Single-transmission line deicing robot and method

A technology for power transmission lines and robots, applied in the installation of electrical components, cables, overhead installation, etc., can solve the problems of high cost and limited capacity, and achieve the effect of improving efficiency, ensuring quality, and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

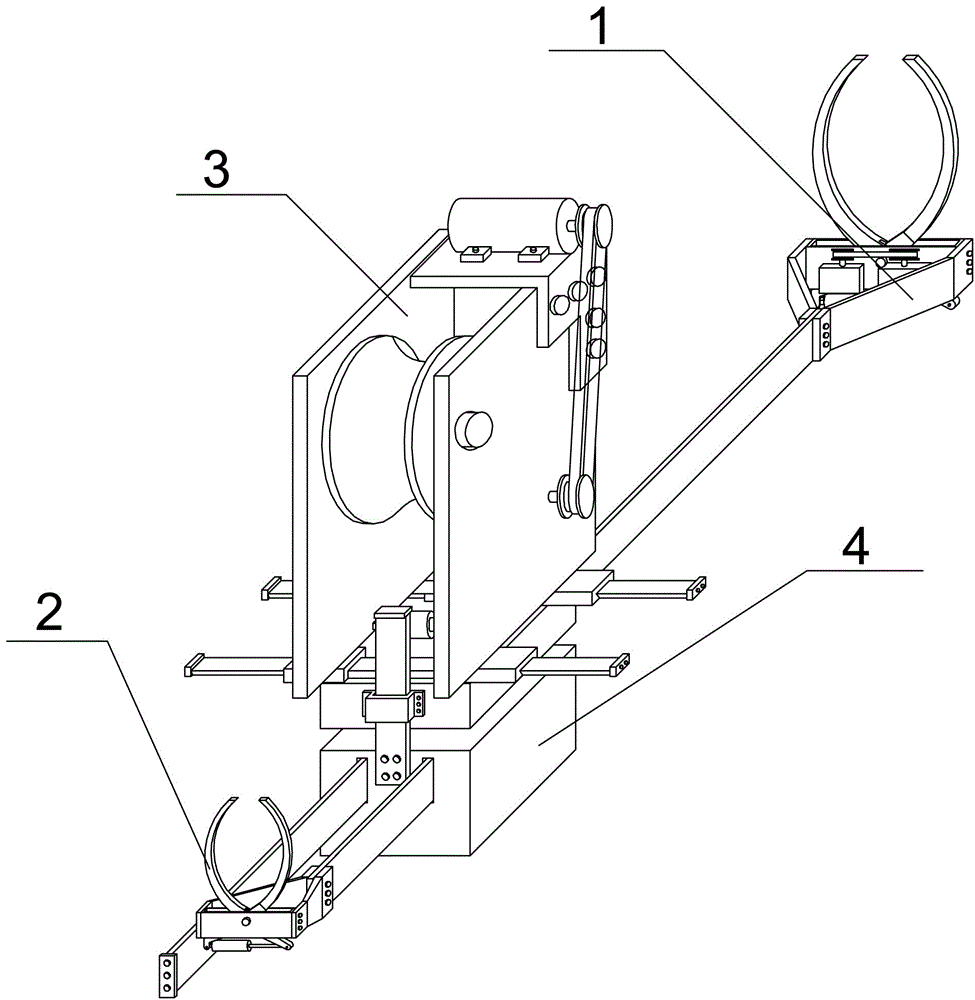

[0041] Such as Figure 1-10 As shown, the single power line deicing robot includes a No. 1 gripper 1, and the No. 1 gripper 1 cooperates with the movement mechanism 4. The No. 2 gripper 2 is installed inside the movement mechanism 4, and the top of the movement mechanism 4 A deicing mechanism 3 is installed.

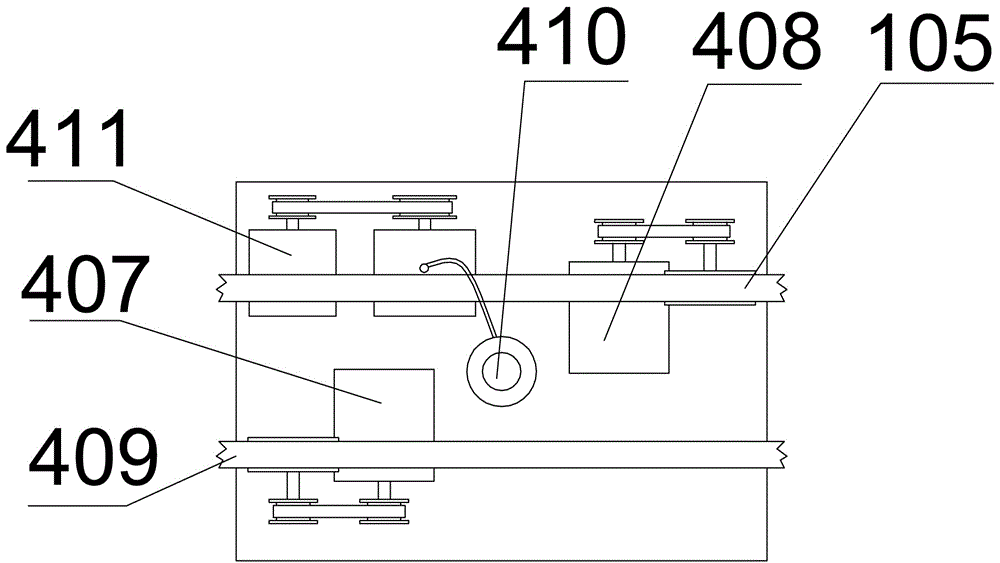

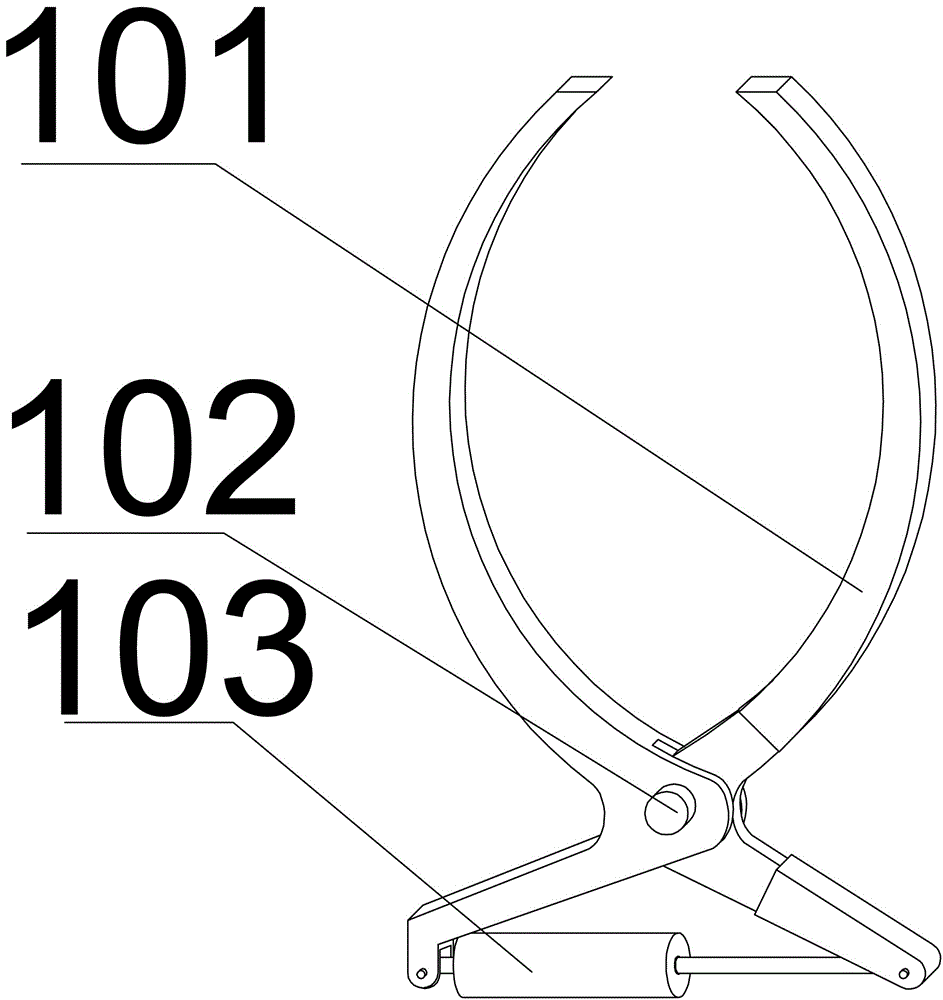

[0042] Further, the No. 1 gripper 1 includes an arc-shaped grab bar 101, the middle parts of the two arc-shaped grab bars 101 are hinged by a pin 102, and the bottom ends of the two arc-shaped grab bars 101 are fixedly connected by a No. 1 hydraulic cylinder 103 , the arc-shaped grab bar 101, the pin shaft 102 and the No. 1 hydraulic cylinder 103 are all arranged inside the No. 1 rectangular box body 106, and a No. 1 connecting rod 104 is fixed on both sides of the No. 1 rectangular box body 106, and two No. 1 connecting rods are connected A long rack 105 is connected to the end of the rod 104 , and a hydraulic drive device 107 is fixed on the side of the No. 1 rectangu...

Embodiment 2

[0050] Adopt the method for deicing of described single power line deicing robot, it comprises the following steps:

[0051] 1) First, the transmission line passes through the roller 303, and the No. 1 gripper 1 is stretched out under the drive of the No. 2 active tooth 408 of the movement mechanism 4, and the arc-shaped grab bar 101 is driven by the No. 1 hydraulic cylinder 103 to clamp the front wire, and then the control The No. 2 driving gear 408 reverses, thereby pulling the deicing mechanism 3 and the moving mechanism 4 to move forward, and at the same time start the No. 1 motor 306 to drive the pulley 308, and the pulley 308 simultaneously drives the No. 1 bevel gear 309 and the No. 2 bevel gear 310 and No. 3 bevel gear 315, drive deicing flywheel 316 by bevel gear, carry out deicing operation by deicing flywheel 316, knock ice bar 312 action and knock on the ice cube on electric wire simultaneously.

[0052] 2) After clearing the ice on a section of wire, the No. 1 gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com