Preparation method of nitrogen-doped rutile tio2/c negative electrode material for sodium ion battery

A sodium-ion battery and rutile-type technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of short cycle life and low negative electrode capacity, achieve long cycle life, improve conductivity, and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

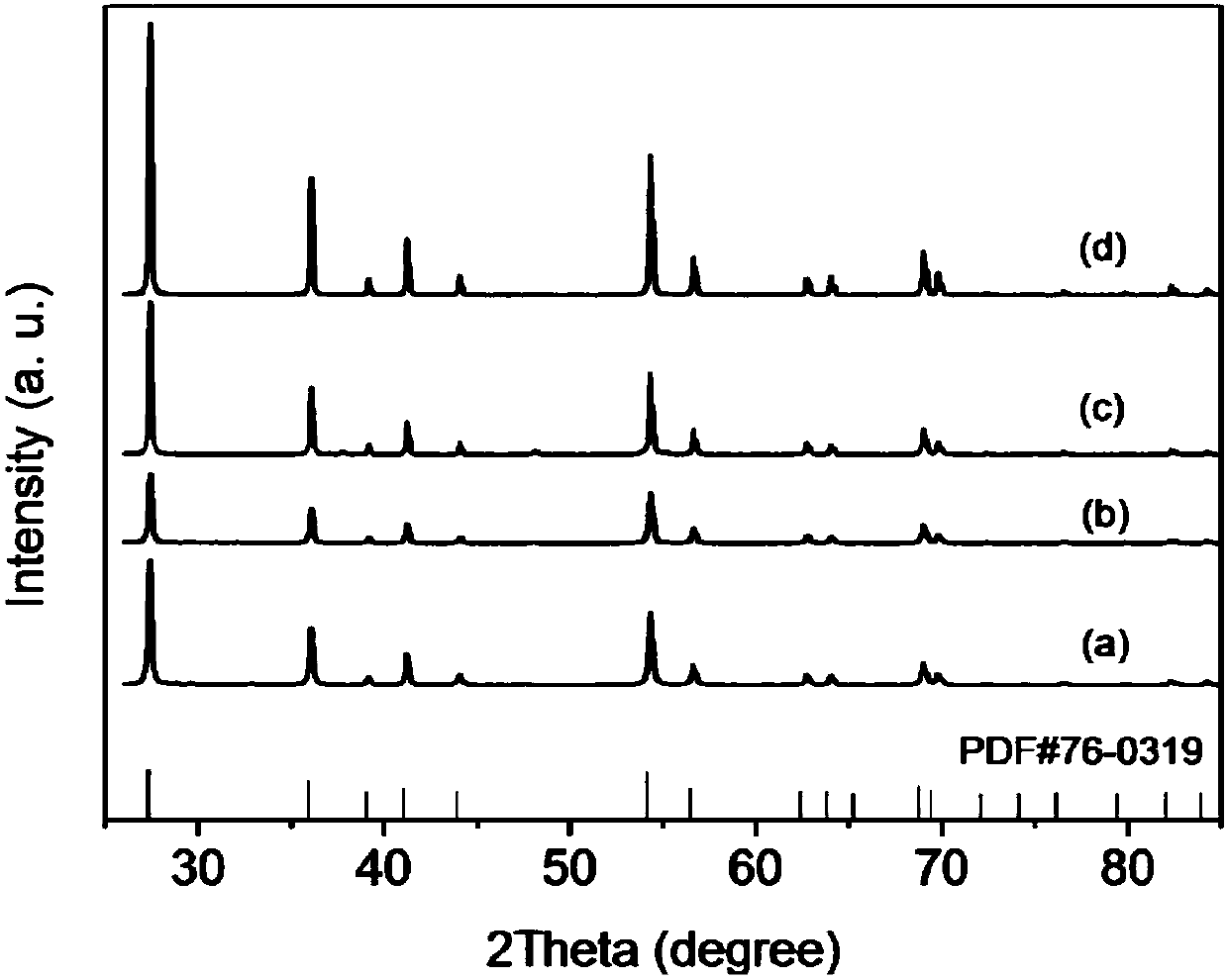

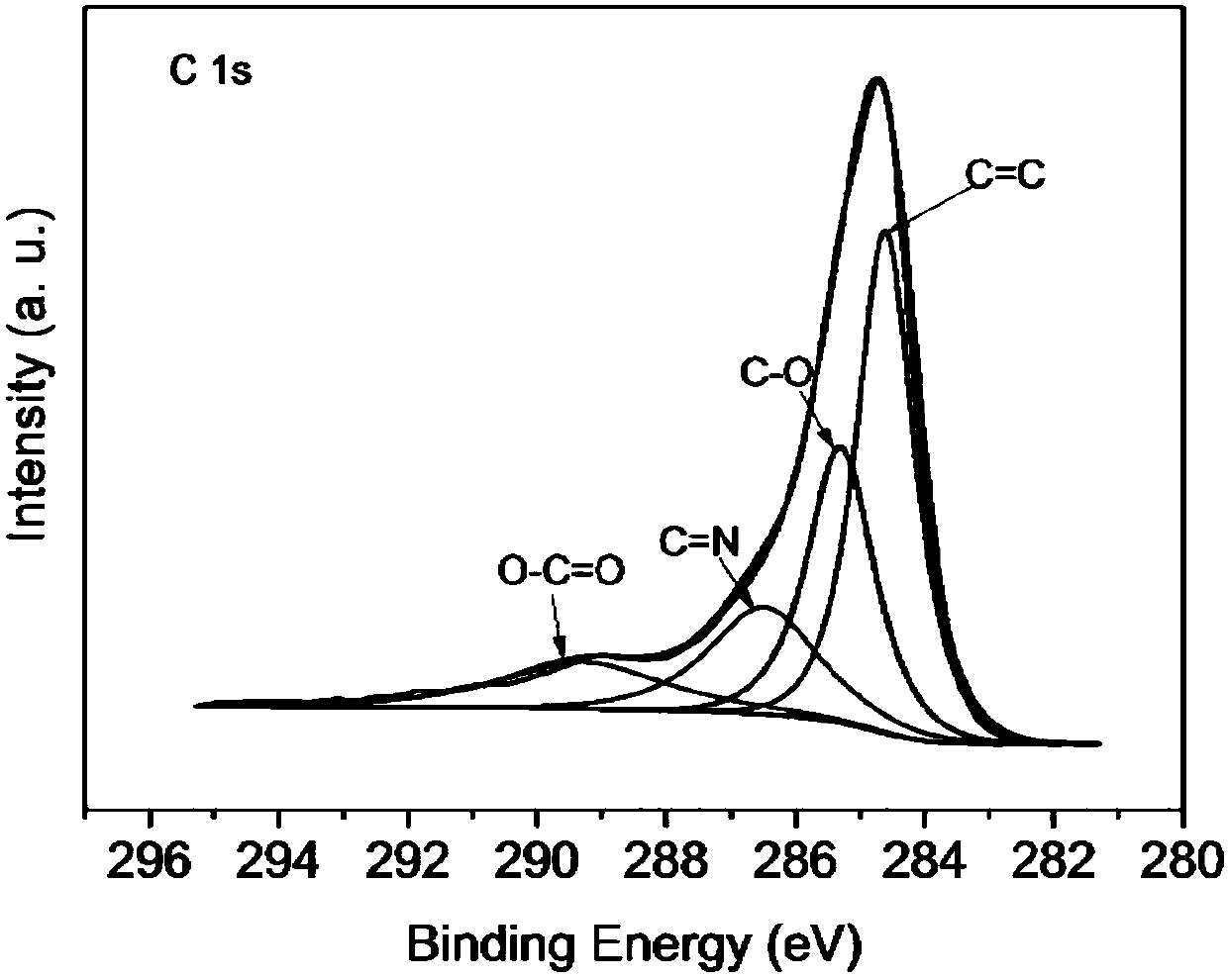

[0031] Dissolve 3.4g of tetrabutyl titanate, 0.8g of melamine and 0.08g of phenolic resin in 60mL of absolute ethanol. After fully stirring, the solution was placed in a planetary ball mill, and ball milled at a speed of 360 r / min for 4 hours. After the ball milling, the solvent was evaporated to dryness to obtain a precursor. The precursors were placed in a tube furnace under Ar / H 2 Under a protective atmosphere, the temperature was raised to 800°C at a heating rate of 10°C / min, and sintered for 6 hours to obtain the target material. Its XRD such as figure 1 as shown in a. It can be seen from the figure that the target material is TiO in rutile phase 2 , the space group is P42 / mnm(136). figure 2 It is a transmission electron microscope picture of the material, and it can be seen that the material is a nano-particle with a small size, and the size of the particle is between 5-50 nm. It is obvious from the TEM image that a layer of carbon is coated around the composite ma...

Embodiment 2

[0034] Dissolve 3.4g of tetrabutyl titanate and 0.2g of phenolic resin in 60ml of ethanol. After fully stirring, the solution was placed in a planetary ball mill, and ball milled at a speed of 360 r / min for 4 hours. After the ball milling, the solvent was evaporated to dryness to obtain a precursor. The precursors were placed in a tube furnace under Ar / H 2 Under a protective atmosphere, the temperature was raised to 800°C at a heating rate of 10°C / min, and sintered for 6 hours to obtain rutile TiO 2 / C Composite. Its XRD such as figure 1 as shown in b. It can be seen from the figure that the target material is TiO in rutile phase 2 , the space group is P42 / mnm(136).

[0035] The pole pieces were prepared according to the method of Example 1 and the batteries were assembled for testing. Figure 4 b records the capacity retention diagram of the battery for the first 50 cycles at a rate of 0.5C. It can be seen from the figure that the second discharge capacity of the batter...

Embodiment 3

[0037] Dissolve 3.4 g of tetrabutyl titanate in 60 mL of ethanol. After fully stirring, the solution was placed in a planetary ball mill, and ball milled at a speed of 360 r / min for 4 hours. After the ball milling, the solvent was evaporated to dryness to obtain a precursor. The precursor was placed in a tube furnace under an Ar protective atmosphere, and the temperature was raised to 800 °C at a heating rate of 10 °C / min, and sintered for 6 h to obtain rutile TiO 2 Material. Its XRD such as figure 1 as shown in c. It can be seen from the figure that the target material is TiO in pure rutile phase 2 , the space group is P42 / mnm(136). Table 2 reports that the carbon content of the material prepared in Example 3 was 0%.

[0038] Tests were carried out after preparing pole pieces and assembling batteries according to the method in Example 1. Figure 4 c records the capacity retention diagram of the battery for the first 50 cycles at a rate of 0.5C. It can be seen from the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com