A simple and stable deceleration method for the reaction flywheel of the balloon basket

A technology of reaction flywheel and balloon basket, which is applied in the direction of electric speed/acceleration control, etc., to achieve the effects of improving safety, low investment cost, and avoiding excessive reaction torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Examples of the present invention are described below. But following embodiment only limits to explain the present invention, and protection scope of the present invention should comprise the whole content of claim, and promptly can realize the whole content of claim of the present invention to those skilled in the art through following embodiment.

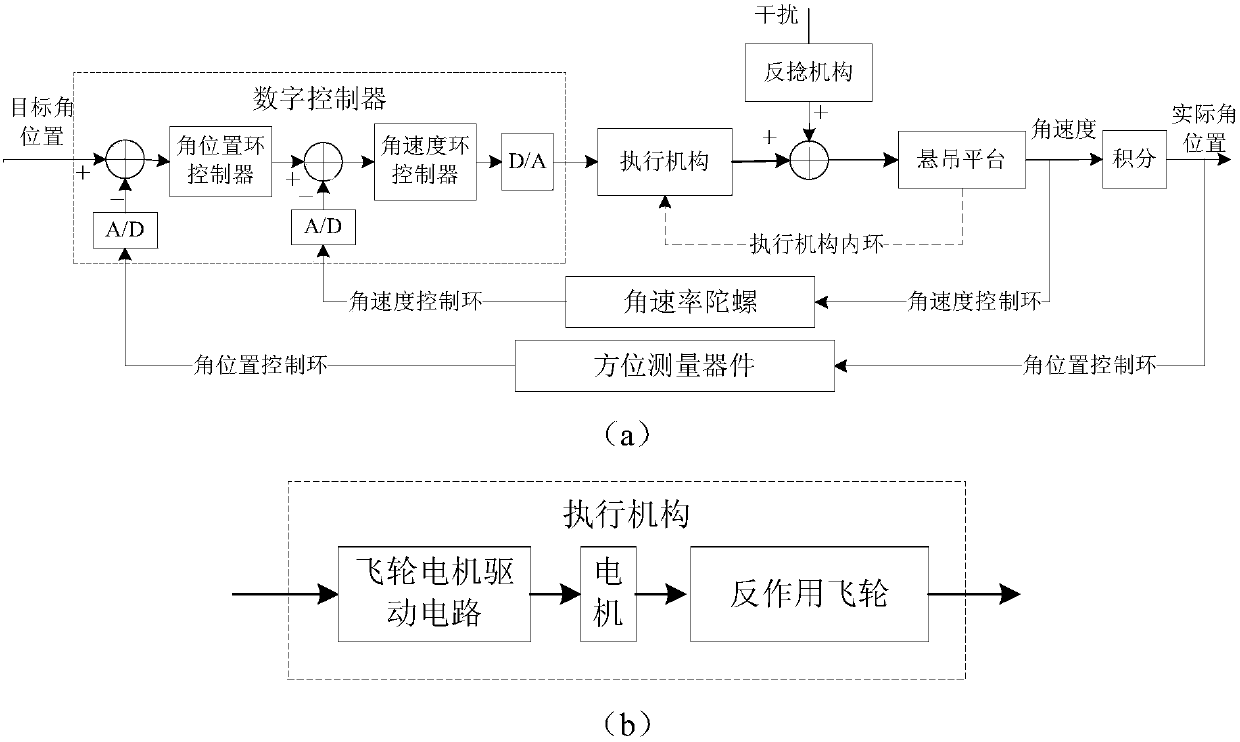

[0025] The present invention will be further described by taking the flywheel deceleration embodiment of a certain balloon basket azimuth control system as an example below.

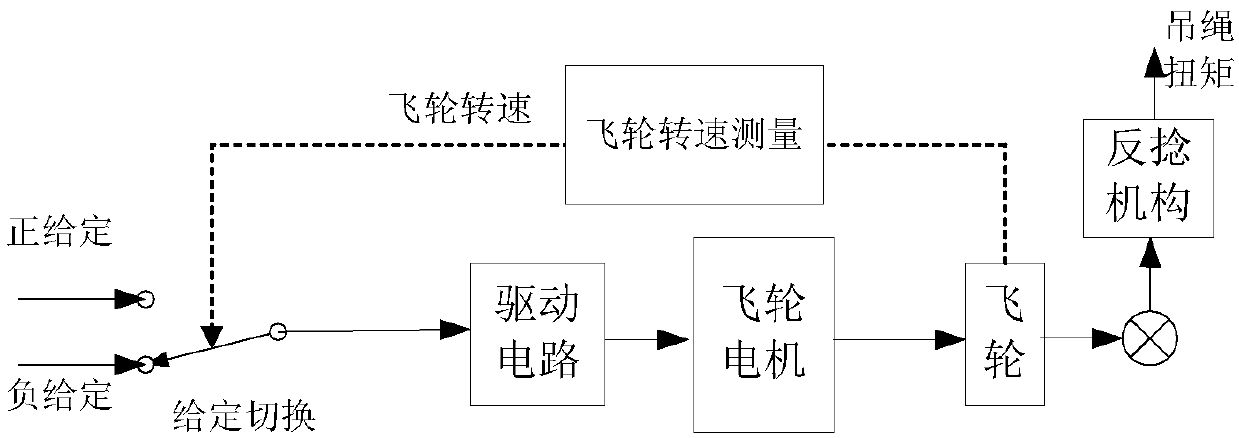

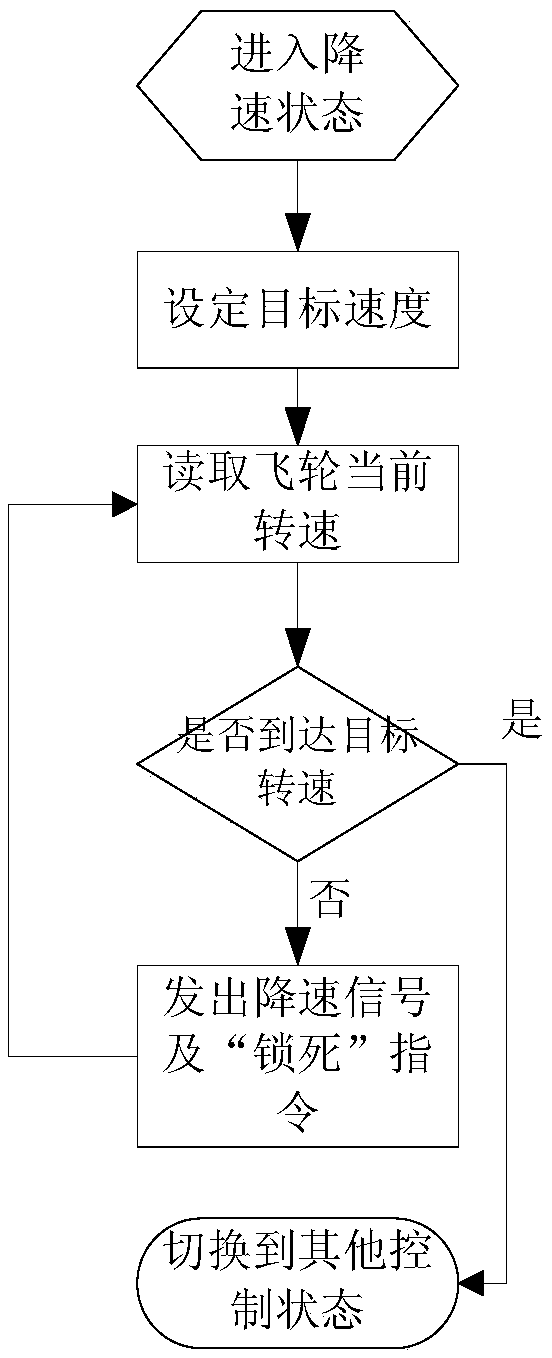

[0026] Such as figure 2 Shown is the structure of the control system when the balloon basket reacts to the flywheel to reduce the speed of the present invention, including the drive circuit, flywheel motor, flywheel, flywheel speed measurement and anti-twisting mechanism. The flywheel speed measurement unit measures the current speed of the flywheel to switch the given value, and the drive circuit converts the given value into a driving voltage and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com