Precision turning method of high-steep aspheric surface with arc-edge diamond tool

A diamond tool, high steepness technology, used in instruments, digital control, control/regulation systems, etc., to reduce manufacturing costs, avoid single-axis installation and control errors, and reduce processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the present invention. within the scope of protection.

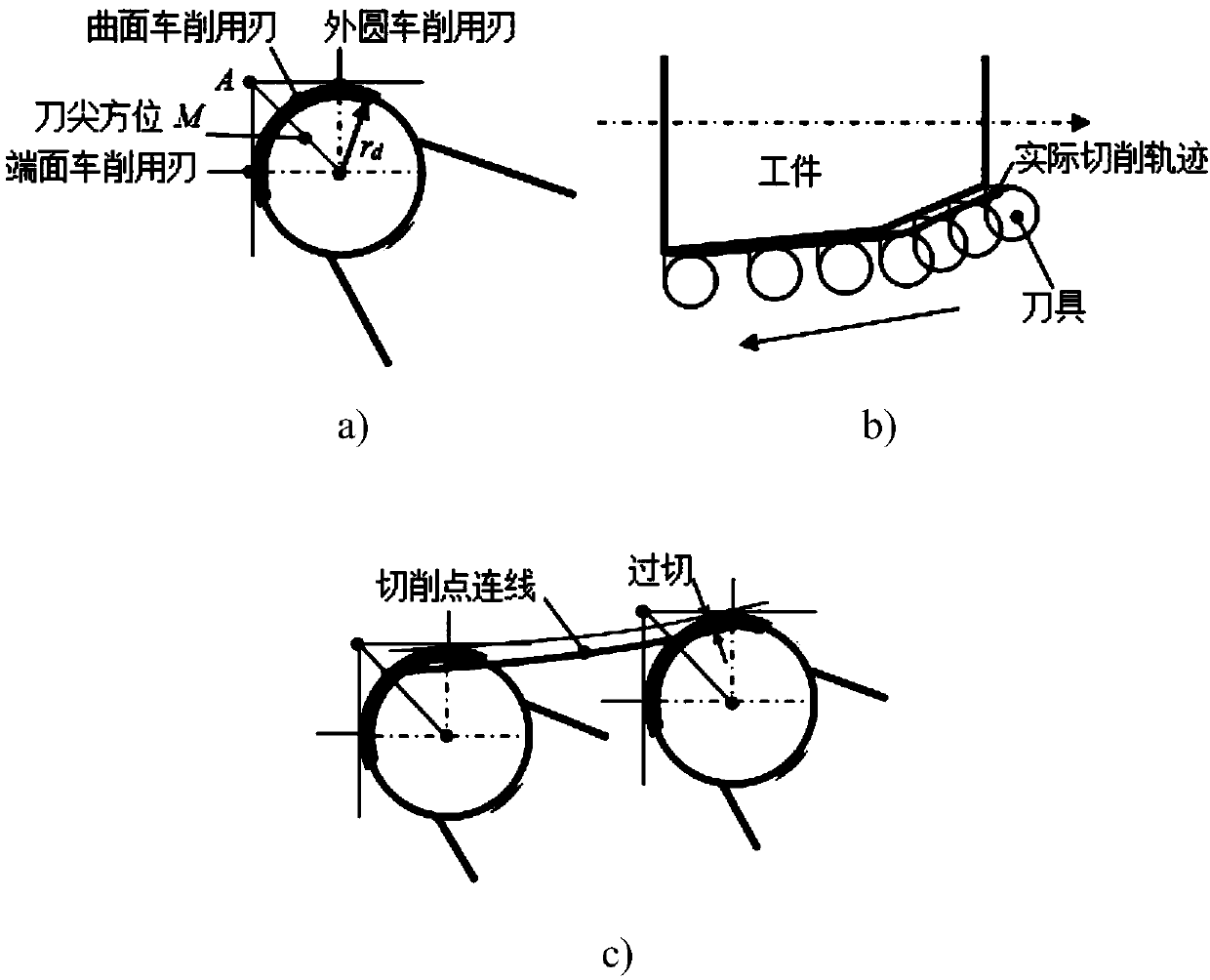

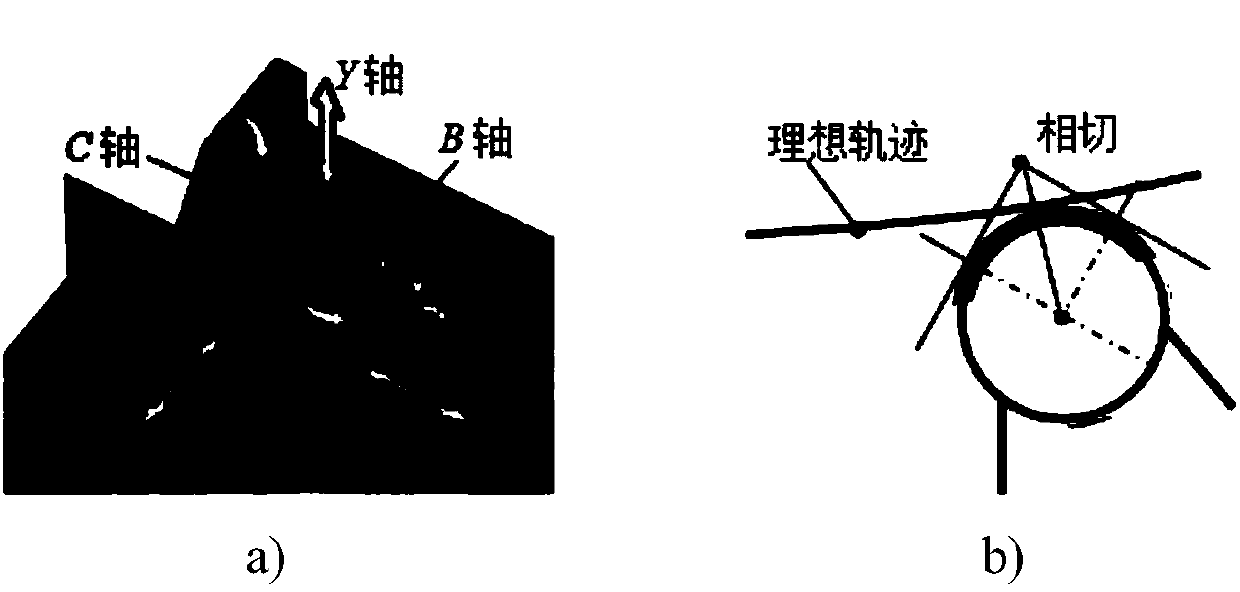

[0040] Under the condition of not increasing the rotation of the B axis, if you want to realize the tangent between the meridional profile curve of the tool and the workpiece at the interpolation point through the interpolation of the X and Z axes, and complete the high-precision turning of the steep aspheric surface, you can choose The arc edge diamond tool with high arc is completed. At present, the arc of the diamond tool edge can be 0.1-0.2μm, such as image 3 As shown, when the arc of the tool edge is tangent to the workpiece, the shape error caus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com