Method for testing bisimide vulcanizing agent

A technology of bisimide and vulcanizing agent is applied in the field of analysis and testing, which can solve the problems of complex vulcanization reaction, and achieve the effects of simple sample preparation, fast testing speed and small sample consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A 20.0 mg sample of 1,3-(citraconimidomethyl)benzene (Perkalink 900) was weighed and added to an agate mortar. Then add 2.0 mg of zinc oxide, 1.0 mg of stearic acid, 1.0 mg of sulfur, and 4.0 mg of vulcanization accelerator NS, and grind the above solids thoroughly to make them evenly mixed.

[0037] Weigh two crucibles of similar weight, one as a reference crucible and one as a sample crucible. Weigh 5.0 mg of the sample prepared above and add it into the sample crucible. Put the reference crucible and sample crucible into the DSC instrument. Nitrogen gas at a flow rate of 50 mL / min was introduced into the DSC. The DSC test conditions are set at a heating rate of 5°C / min, and the temperature range is 100°C to 200°C.

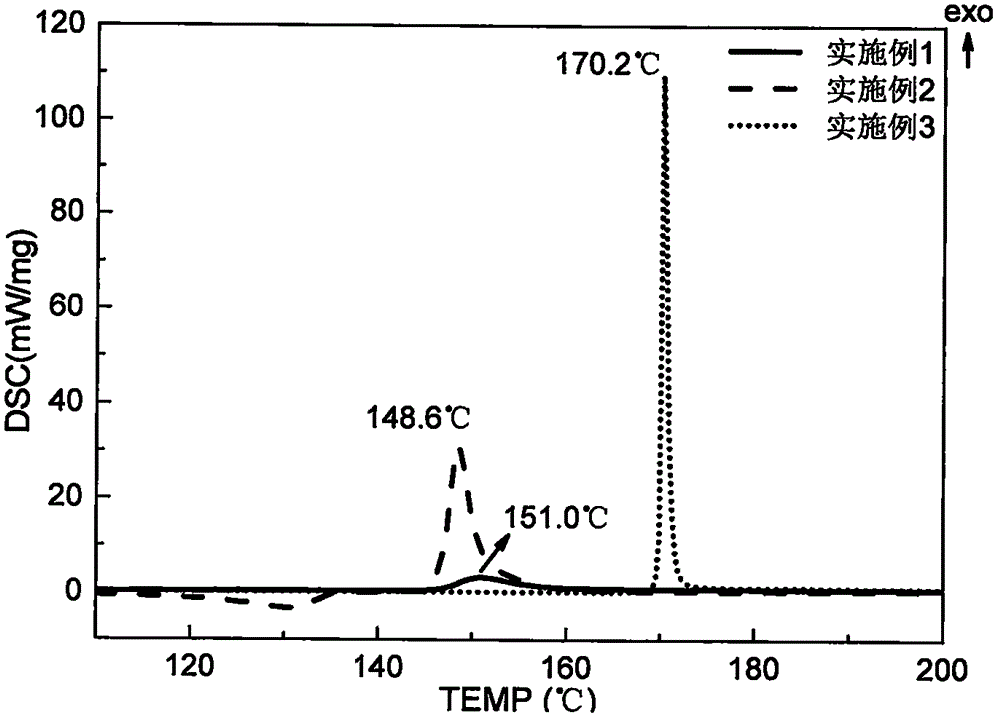

[0038] The measured DSC spectrum is shown in the accompanying drawing, figure 1 .

Embodiment 2、3

[0040] Sample preparation method and DSC test conditions are the same as in Example 1, and the specific sample preparation formula is shown in Table 1

[0041] Table 1 Example 2~3 sample preparation formula (consumption of each component: mg)

[0042] Example 2 Example 3 1,6-Bismaleimidohexane (BMH) 20.0 N, N'-m-phenylene bismaleimide (PDM) 20.0 Zinc oxide 2.0 2.0 stearic acid 1.0 1.0 sulfur 1.0 1.0 Vulcanization accelerator NS 4.0 4.0

[0043] Table 2 Maximum exothermic peak temperature

[0044] exothermic peak, ℃ Exothermic peak area, J / g Example 1 151.0 22.14 Example 2 148.6 192.05 Example 3 170.2 176.13

[0045] figure 1 And in table 2, it can be seen that embodiment 1, 2, 3 all have reaction exothermic peaks, illustrate that they all can react with sulfur. Embodiment 1, 2 reaction exothermic temperature is lower, and their activity with sulfur reaction is higher, reacts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com