Clamping loading and sealing structure for capacitor sealing strength detection

A technology of strength detection and sealing structure, which is applied in the direction of engine sealing, measuring devices, strength characteristics, etc., can solve the problems of affecting the sealing effect, unreliable sealing, and unsealable, etc., and achieve the effect of reasonable structure, reliable sealing, and reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

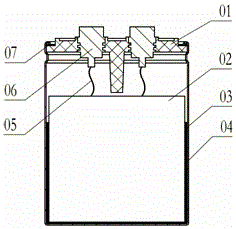

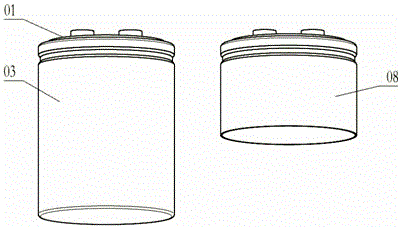

[0029] Such as figure 1 As shown, the aluminum electrolytic capacitor is mainly composed of a cover plate 01, a core package 02, an aluminum shell 03, a fixing glue 04, a pin 05, an aluminum terminal 06, and a sealing ring 07. The core package 02 is made of aluminum foil and electrolytic paper stacked and wound, placed inside the aluminum shell 03, and fixed by fixing glue 04 or thimble; the pin 05 is drawn out from the foil and riveted with the aluminum terminal 06 on the cover plate 01; Realize that the sealing ring 07 on the cover plate 01 is crimped and tightly pressed by the aluminum shell 03 to complete the sealing of the capacitor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com