A hydraulic device and control method for successive supercharging diesel engines based on exhaust gas utilization

A technology of sequential pressurization and hydraulic devices, which is applied in the direction of fluid pressure actuators, mechanical equipment, servo motors, etc., can solve the problems of not using the sequential pressurization system, and achieve the effect of improving utilization rate and alleviating response delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

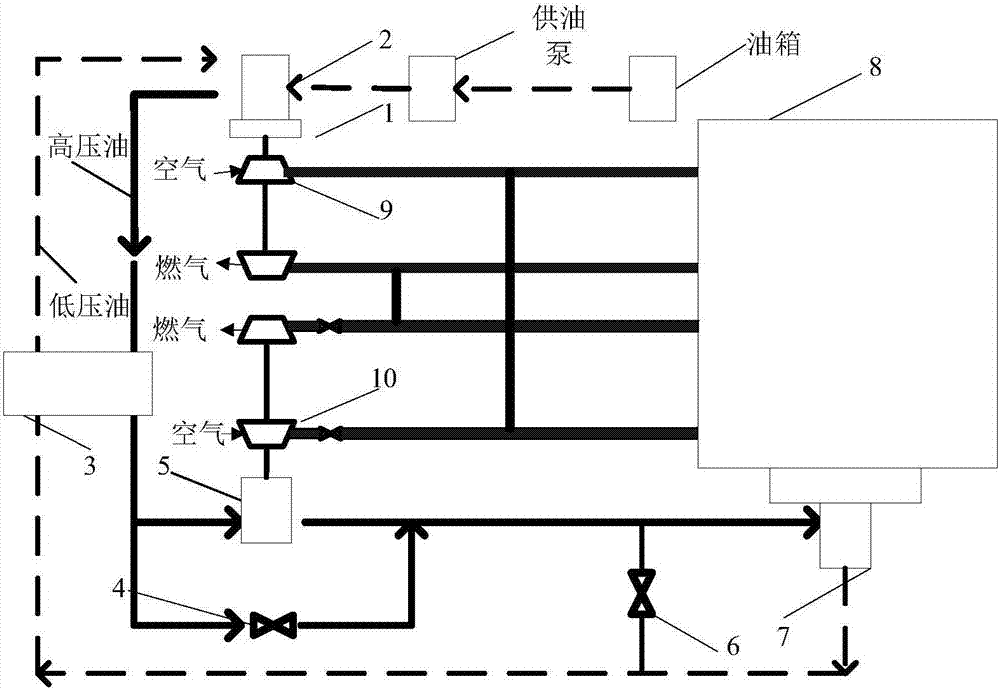

[0020] A sequential supercharging diesel engine hydraulic device based on exhaust gas utilization, characterized in that it includes an oil supply pump, a hydraulic pump 2, a speed reduction mechanism 1, a main control supercharger 9, a controlled supercharger 10, a first hydraulic motor 5, a second Two hydraulic motors 7 and diesel engines 8, the oil supply pump is connected with the hydraulic pump 2, the hydraulic pump 2 is connected with the reduction mechanism 1 and installed on the main control supercharger 9, and the first hydraulic motor 5 is installed on the controlled supercharger 10, the second hydraulic motor 7 is installed on the front end of the auxiliary propulsion crankshaft of the diesel engine 8, and the first hydraulic motor 5 and the second hydraulic motor 7 are also connected in parallel with the first bypass valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com