Trolley gantry stabilizing system for dust collector

A technology for dust collectors and car doors, which is used in wellbore lining, tunnel lining, underground chambers, etc., can solve problems such as poor stability and anti-vibration amplitude, safety accidents, etc., and achieve good stability and anti-amplitude effect. Good anti-vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

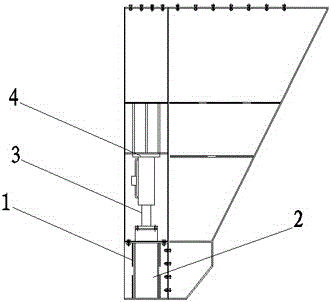

[0008] see figure 1 , a trolley door frame stabilization system for a dust collector, which includes an outer jacket 1, an inner jacket 2, a jacking cylinder 3, and a jacking cylinder seat 4, the outer jacket 1 is provided with an inner jacket 2, and the inner jacket 2 is provided with a top Lifting oil cylinder 3, jacking oil cylinder 3 top is provided with jacking oil cylinder seat 4.

[0009] In the present invention, the jacket is arranged in the lower longitudinal beam of the mast, an inner sleeve is arranged inside the jacket, a jacking oil cylinder is arranged above the inner jacket, and a jacking cylinder seat is arranged above the jacking oil cylinder. , when it is necessary to jack up the template, first operate the inner sleeve to drive the jacking cylinder to move downward until the inner sleeve is stable, then operate the jacking cylinder to move upward, and the jacking cylinder drives the jacking cylinder seat to move together until the jacking cylinder seat is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com