Pneumatic cleaning and drag reduction device for reciprocating coal cutting path of plow head

A technology of coal plow and reciprocating motion is applied in the field of pneumatic cleaning and drag reduction devices for the reciprocating coal cutting path of the plow head of the coal plow, and can solve the problem of low power utilization rate of the electric motor, increased wear of the plow head of the coal plow, Head bottom wear and other problems, to reduce maintenance intensity, improve work efficiency, reduce wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

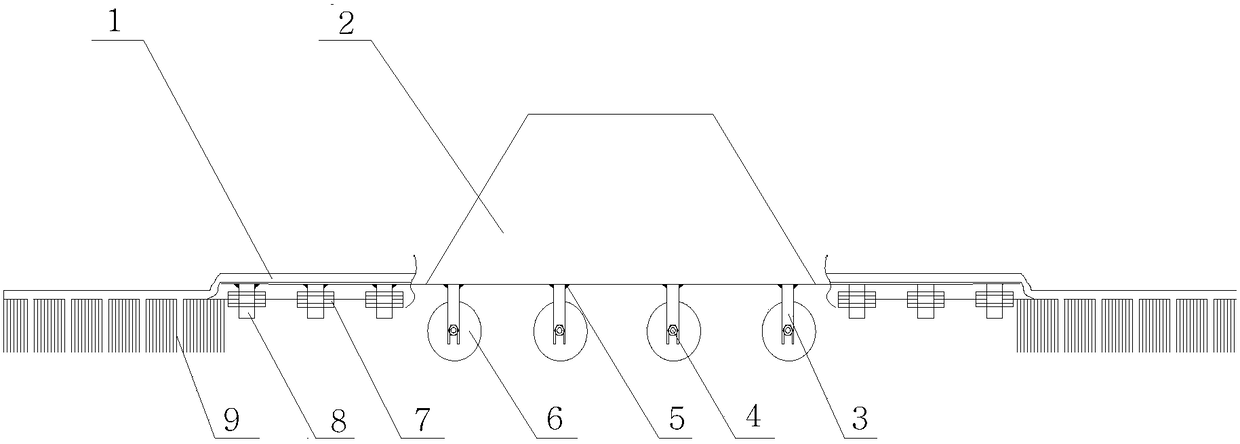

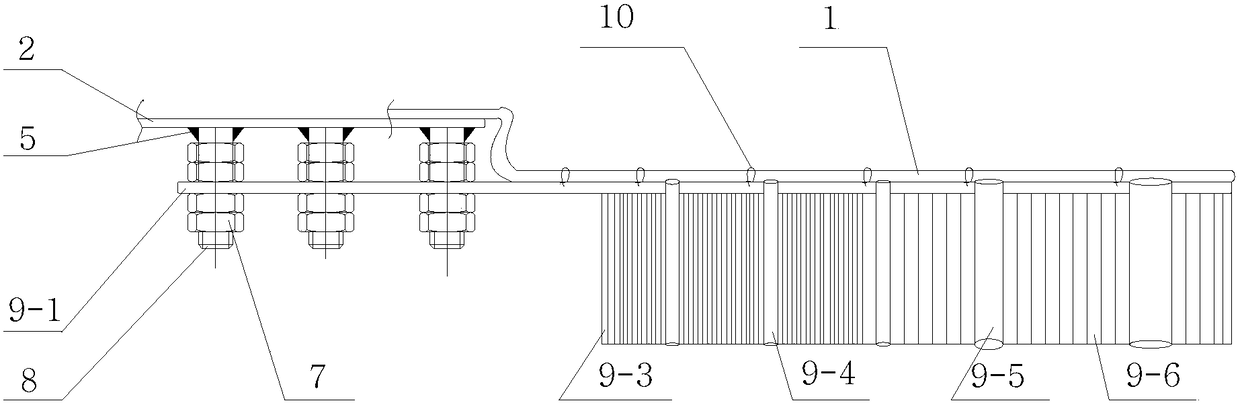

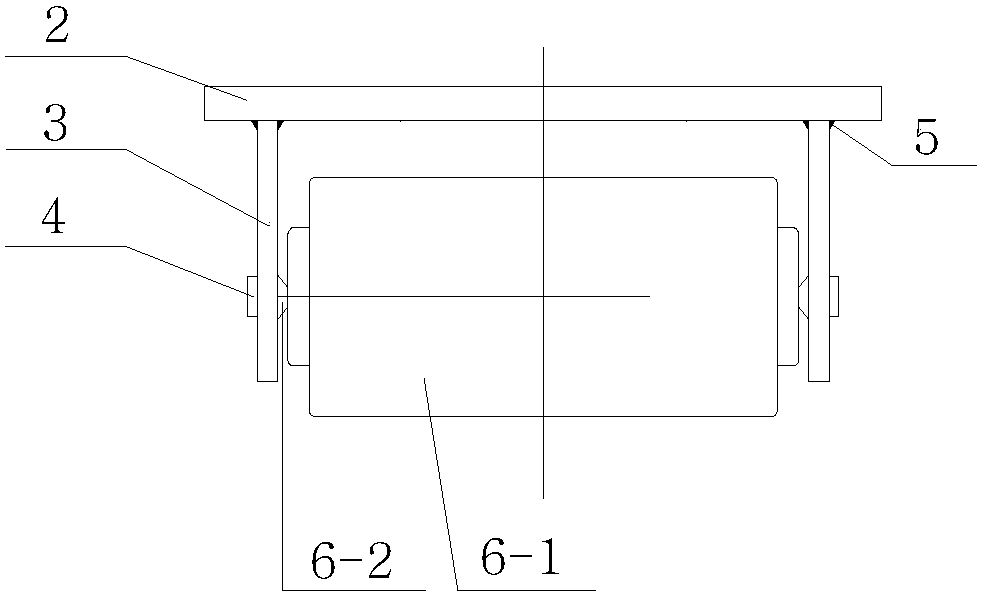

[0022] Working principle: Pneumatic cleaning brush 9 is used to clean the accumulated gravel or coal on the plow head 2 cutting coal reciprocating path during the working process of the coal plow, effectively ensuring the reduction of obstacles in the coal cutting reciprocating path. The group pulley 6 carries the plow head 2 and moves along the coal cutting reciprocating path, so that the sliding friction of the plow head 2 becomes the rolling friction of the drag-reducing pulley 6, reducing the wear of the plow head.

[0023] Equipment composition:

[0024] A plow plow head reciprocating coal cutting path pneumatic cleaning drag reduction device includes a strong pressure gas delivery pipeline 1, welded steel plate 3, drag reduction pulley 6, thread fastening device 7, welded thread column 8, pneumatic cleaning brush 9.

[0025] Working process: such as figure 1 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com