Tower type garage

A garage and tower technology, applied in the field of garages, can solve the problems of complex construction cost, occupation of fire protection equipment, and large area occupied by vehicle driving passages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings. Obviously, the described embodiments are only some of the embodiments of the invention.

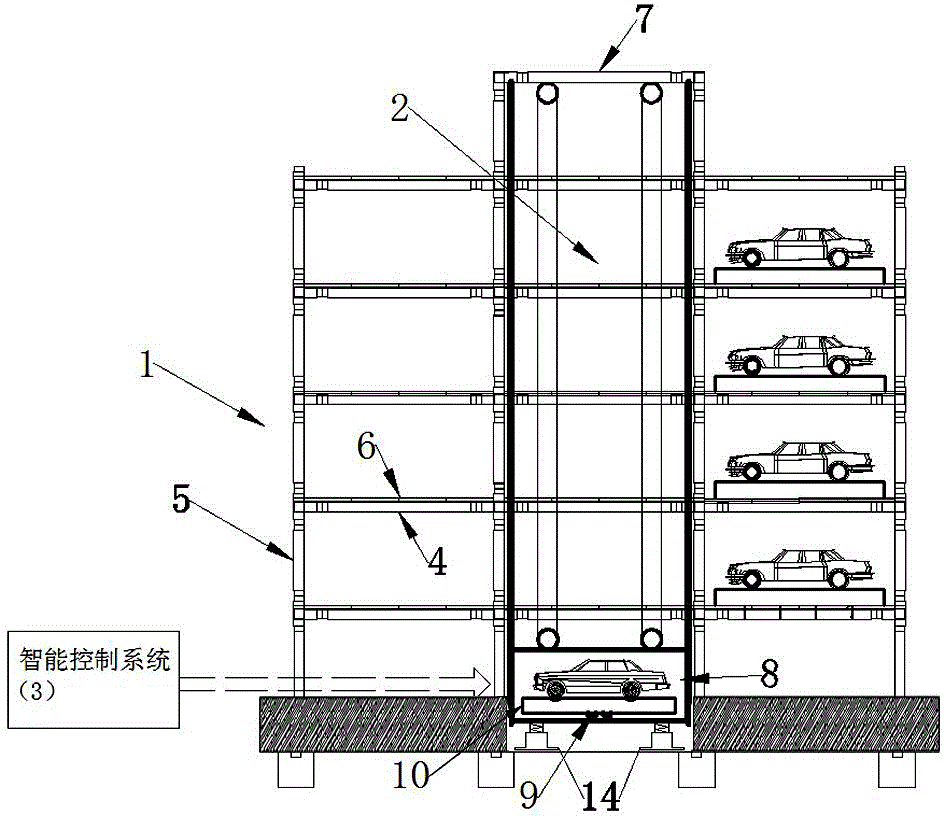

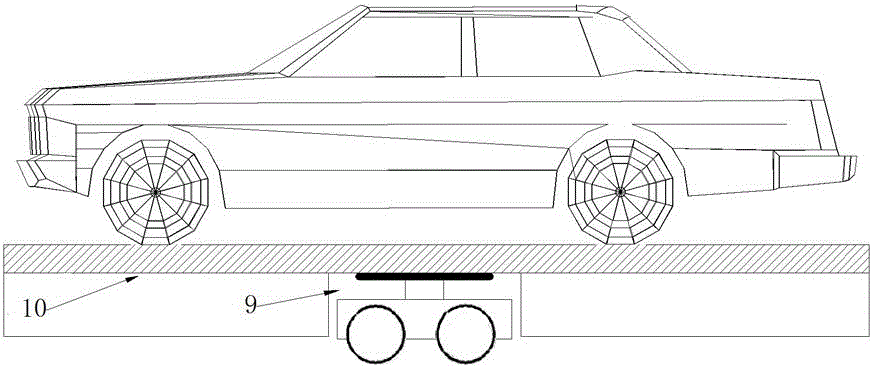

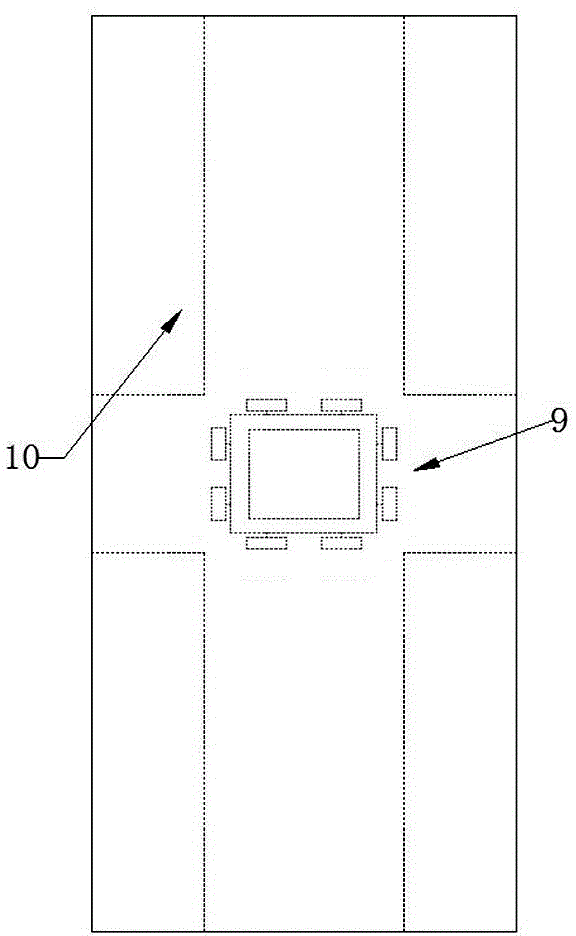

[0033] Such as figure 1 with figure 2 , image 3 Examples shown, such as figure 1 As shown in the tower garage, the main structure 1 of the garage is a multi-layer structure composed of beams 4, columns 5 and floors 6. The main structure 1 is ordinary reinforced concrete, steel concrete, prestressed concrete, steel pipe concrete, steel or pressure One type or a combination of two or more types of steel plates. The geometric center of the main structure 1 is provided with an elevator shaft 7, and a hoist elevator 2 is installed in the elevator shaft 7 to transport vehicles up and down. The mobile transport device 9 and the movable car pallet 10 are operated under the control of the intelligent control system 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com