A kind of preparation method of aluminum oxide flocculant inverse microemulsion

The technology of inverse microemulsion and flocculant is applied in the preparation of sodium acrylate-acrylamide flocculant inverse microemulsion, and in the field of preparation of stable inverse microemulsion, and can solve the problems that heat is difficult to release, intensify, and rise as soon as possible. Achieve the effect of low oil-water ratio, slowing down the polymerization rate and increasing the molecular weight of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

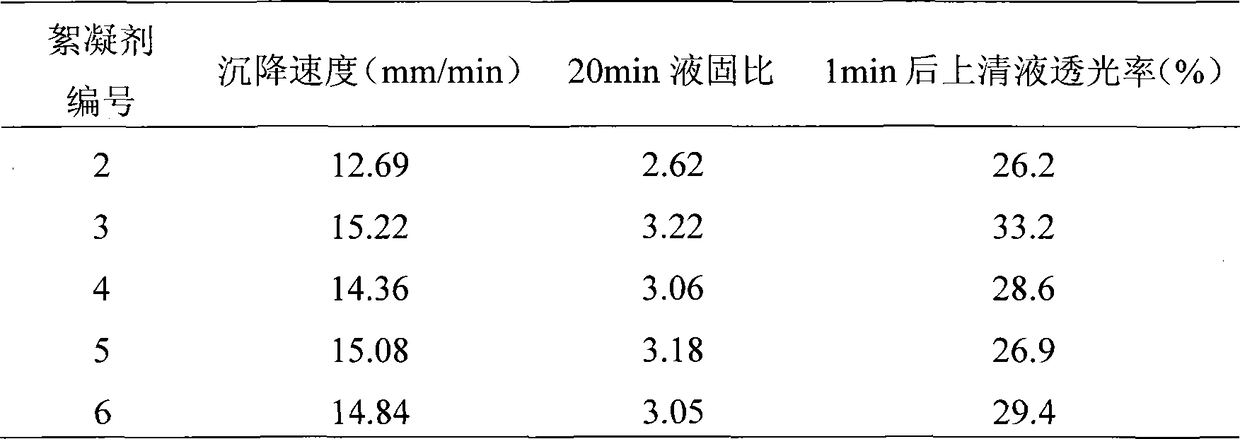

Image

Examples

Embodiment 1

[0022] Weigh 20g of AEO-9 and dissolve it in 100mL of dichloroethane, add 2g of ethyl acrylate, and heat up to reflux. 0.02g AIBN (azobisisobutyronitrile) was dissolved in 5mL toluene, the toluene solution of initiator AIBN (azobisisobutyronitrile) and 10g of N-vinyl n-butyl ether were slowly added dropwise, and kept Reflux for 10 hrs, stop the reaction, and distill off the solvent and residual monomers under reduced pressure to obtain a self-made graft emulsifier.

Embodiment 2

[0024] Weigh 45.9g of acrylic acid and 30g of acrylamide, dissolve them in 23.2g of distilled water, cool to 15°C, add 50% sodium hydroxide solution dropwise under stirring to neutralize to pH 5.5, and control the neutralization temperature to 6 dalton.

Embodiment 3

[0026]Weigh 45.9g of acrylic acid and 30g of acrylamide, dissolve them in 23.2g of distilled water, cool to 15°C, add 50% sodium hydroxide solution dropwise under stirring to neutralize to pH 6.0, and control the neutralization temperature to 7 dalton.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com