Process for extracting astaxanthin from prawn shells

An extraction process, astaxanthin technology, is applied in the field of astaxanthin extraction from shrimp shells, which can solve the problems of low astaxanthin extraction effect, difficulty in expanding production, and long time consumption, and achieve low cost, short extraction time, small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] 1) Soak the shrimp shells in 1mol / L hydrochloric acid, place on a shaker and shake until no bubbles are generated, then filter off the hydrochloric acid, rinse the shrimp shells with distilled water until neutral, then dry them with a freeze dryer, and crush them into powder. Cross 100 mesh molecular sieves to obtain shrimp shell powder for subsequent use;

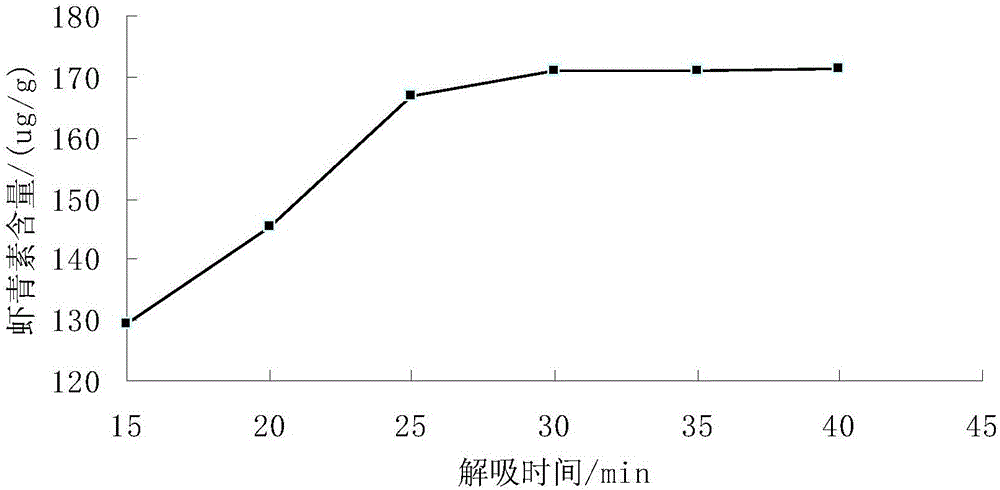

[0095] 2) Put 1g of shrimp shell powder in a flask, add 8mL of 90v / v% ethanol, stir well, and desorb for 25min; L of sodium hydroxide solution, extracted for 6 min, filtered, and the filter residue was repeated once for the above extraction operation, and the extract was collected (the extract was clear and transparent, bright in color);

[0096] 3) The obtained extract was extracted with dichloromethane, and the extract phase was collected and dried to obtain 0.145 g of astaxanthin. After calculation, the extraction rate is 14.5%.

Embodiment 2

[0098] 1) Soak the shrimp shells in 1.5mol / L hydrochloric acid, place on a shaker and shake until no bubbles are generated, then filter off the hydrochloric acid, rinse the shrimp shells with distilled water until neutral, then dry them with a freeze dryer and grind them into powder , through a 100-mesh molecular sieve to obtain shrimp shell powder, which is set aside;

[0099] 2) Put 1g of shrimp shell powder in a flask, add 16mL of 100v / v% ethanol, stir well, and desorb for 40min; then place the flask in a constant temperature tank at 70°C, and add 30mL of it, which is preheated to 70°C to a concentration of 0.5mol / L potassium hydroxide solution, extract for 8min, filter, and the filtrate is the extract (the extract is clear and transparent, bright in color);

[0100] 3) The obtained extract was extracted with dichloromethane, and the extract phase was collected and dried to obtain 0.150 g of astaxanthin. After calculation, the extraction rate is 15.0%.

Embodiment 3

[0102] 1) Soak the shrimp shells in 1.2mol / L hydrochloric acid, place on a shaker and shake until no bubbles are generated, then filter off the hydrochloric acid, rinse the shrimp shells with distilled water until neutral, then dry them with a freeze dryer and grind them into powder , through a 100-mesh molecular sieve to obtain shrimp shell powder, which is set aside;

[0103] 2) Put 1g of shrimp shell powder in a flask, add 10mL of 70v / v% ethanol, stir well, and desorb for 35min; then place the flask in a constant temperature bath at 72°C, and add 20mL of it, which is preheated to 72°C to a concentration of 1.5mol / L of calcium hydroxide solution, extract for 4min, filter, repeat the above-mentioned extraction operation twice for the filter residue, and collect the extract (the extract is clear and transparent, bright in color);

[0104] 3) The obtained extract was extracted with chloroform, and the extract phase was collected and dried to obtain 0.143 g of astaxanthin. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com