Rapid repair mortar and repair process special for autoclaved aerated concrete slab

A technology of repairing mortar and autoclaved aeration, which is applied in the directions of climate sustainability, sustainable waste treatment, solid waste management, etc. The effect of improving the site, repairing efficiency, and reducing the repairing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

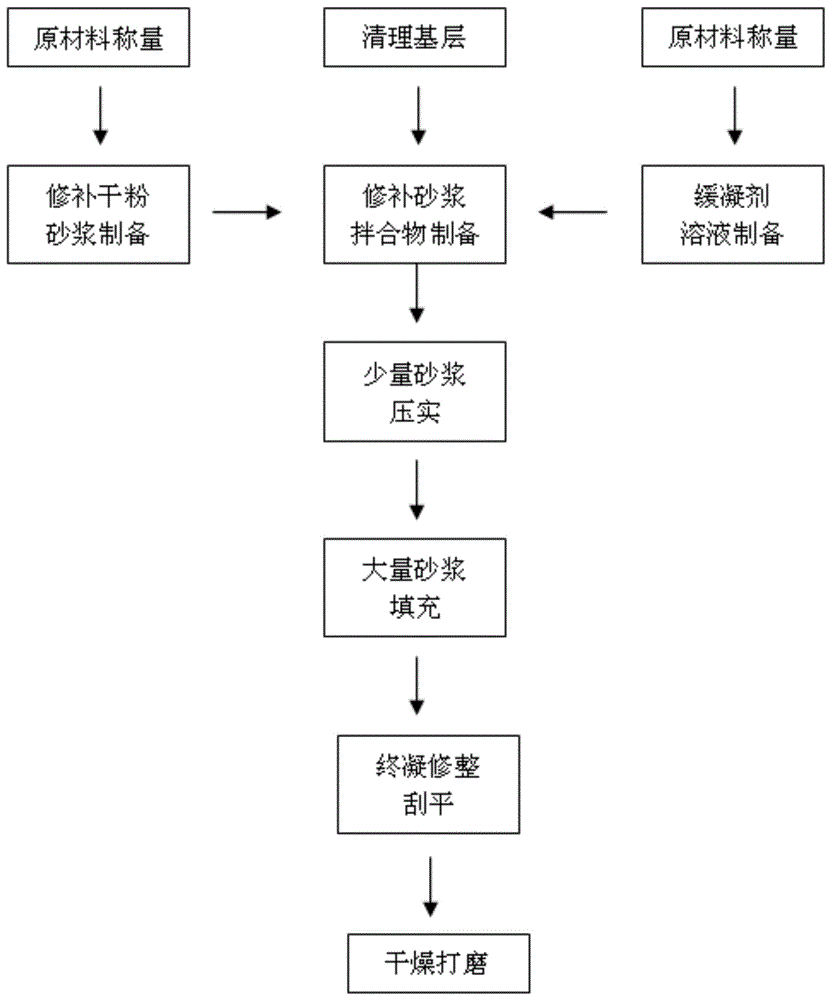

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Mix 60kg of building gypsum powder, 30kg of primary fly ash, 9.1kg of fine sand, 0.8kg of redispersible latex powder and 0.1kg of hydroxypropyl methyl cellulose ether and stir evenly, add 28kg of tap water and stir evenly , That is, repair mortar mixture.

[0034] Test the compressive strength, expansion rate and setting time of the obtained repair mortar mixture according to the standard, and carry out the repair work according to the repair process. The compressive strength is 1.2 MPa greater than that of the aerated concrete plate, and the expansion rate will not increase after 4 hours , the final setting time is 6 minutes, the color of the repair mortar is basically the same as that of the aerated concrete slab after drying, and the repair body has no cracks for 3 months. Compared with the repairing mortars disclosed in CN103951340A and CN102535733A, the final setting time is too short, although the repairing speed is greatly accelerated, but the operatin...

Embodiment 2

[0035] Embodiment 2: 60kg white cement, 30kg primary fly ash, 9.1kg fine sand, 0.8kg redispersible latex powder and 0.1kg hydroxypropyl methyl cellulose ether are mixed and stirred evenly, and 28kg tap water is added and stirred evenly, That is, the repair mortar mixture is obtained.

[0036]Test the compressive strength, expansion rate and setting time of the obtained repair mortar mixture according to the standard, and carry out the repair work according to the repair process. The compressive strength is 2.5 times that of the aerated concrete plate, and the shrinkage rate still increases after 28 days , the final setting time is 4 hours, the color of the repair mortar is basically consistent with that of the aerated concrete slab after drying, and the repair body will have cracks within one month. Compared with the repair mortars disclosed in CN103951340A and CN102535733A, the final setting time does not change, the repair efficiency does not increase significantly, and it i...

Embodiment 3

[0037] Embodiment 3: in the repair dry powder mortar that makes in embodiment 1, add 28kg concentration and be the borax aqueous solution of 0.40% and stir evenly, obtain the repair mortar mixture.

[0038] Test the compressive strength, expansion rate and setting time of the obtained repair mortar mixture according to the standard, and carry out the repair work according to the repair process. The compressive strength is 0.8 MPa greater than that of the aerated concrete plate, and the expansion rate will not increase after 4 hours , the final setting time is 10 minutes, the color of the repair mortar is basically the same as that of the aerated concrete slab after drying, and the repair body has no cracks for 3 months. Compared with the repairing mortars disclosed in CN103951340A and CN102535733A, the final setting time is too short, although the repairing speed is greatly accelerated, but the operating time of the repairing mortar mixture is too short, which is not suitable f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com