C30 tailing sand anti-washout concrete and preparing method thereof

A technology of tailings sand and concrete, which is applied in the field of building materials, can solve the problems of inability to meet the requirements of underwater construction and low concrete strength, and achieve the effects of reducing concrete costs, low production costs, and easy-to-obtain materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

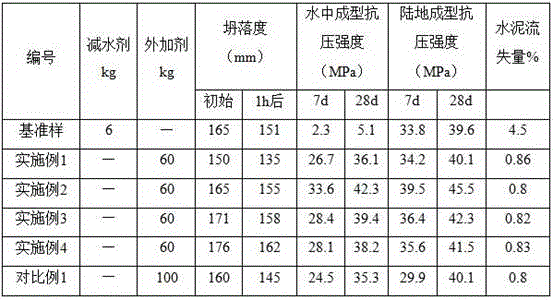

Examples

Embodiment 1

[0034] This embodiment provides a C30 tailings sand anti-dispersion concrete. The amount of materials per cubic concrete is as follows: 300 kg of cement, 100 kg of activated tailings, 350 kg of coarse tailings, 400 kg of machine-made sand, 1100 kg of stone, 150 kg of water, and 60 kg of admixture.

[0035] The preparation method of the above-mentioned C30 tailings sand anti-dispersion concrete comprises the following steps:

[0036] 1) Screening: Take the tailings sand according to the amount of the material, and obtain two kinds of tailings sand with a size of less than 80 μm or more than 80 μm through screening, and the tailings sand with a size of more than 80 μm is coarse tailings sand;

[0037] 2) Calcination: calcining tailings sand below 80 μm at 600-800°C for 3 hours, and cooling to room temperature for 0.5-2 hours;

[0038] 3) Weighing: Take cement, machine-made sand, stone, water, admixture, active tailings sand, and coarse tailings sand according to the amount of ma...

Embodiment 2

[0049] This embodiment provides a kind of C30 tailings sand anti-dispersion concrete. The amount of each material in each cubic concrete is as follows: the amount of each material in each cubic concrete is 240 kg of cement, 160 kg of activated tailings sand, 300 kg of coarse tailings sand, 450 kg of machine-made sand, and 1056 kg of melon seeds. , water 160kg, admixture 60kg.

[0050] The preparation method of the above-mentioned C30 tailings sand anti-dispersion concrete is the same as that of Example 1.

[0051] The composition and preparation method of the above-mentioned admixture are the same as in Example 1.

Embodiment 3

[0053] This embodiment provides a C30 tailings sand anti-dispersion concrete. The amount of materials in each cubic concrete is as follows: 280 kg of cement, 120 kg of activated tailings sand, 450 kg of coarse tailings sand, 300 kg of machine-made sand, 950 kg of melon seeds, 130 kg of water, and 60 kg of admixture .

[0054] The preparation method of the above-mentioned C30 tailings sand anti-dispersion concrete is the same as that of Example 1.

[0055] The composition and preparation method of the above-mentioned admixture are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com