Dynamic membrane anaerobic-aerobiotic wastewater treatment method based on microbiological fuel cell

A sewage treatment method and fuel cell technology, applied in the field of sewage treatment, can solve the problems of high investment cost, low efficiency, and large equipment footprint, and achieve the effects of high operating costs, increased concentration, and large power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

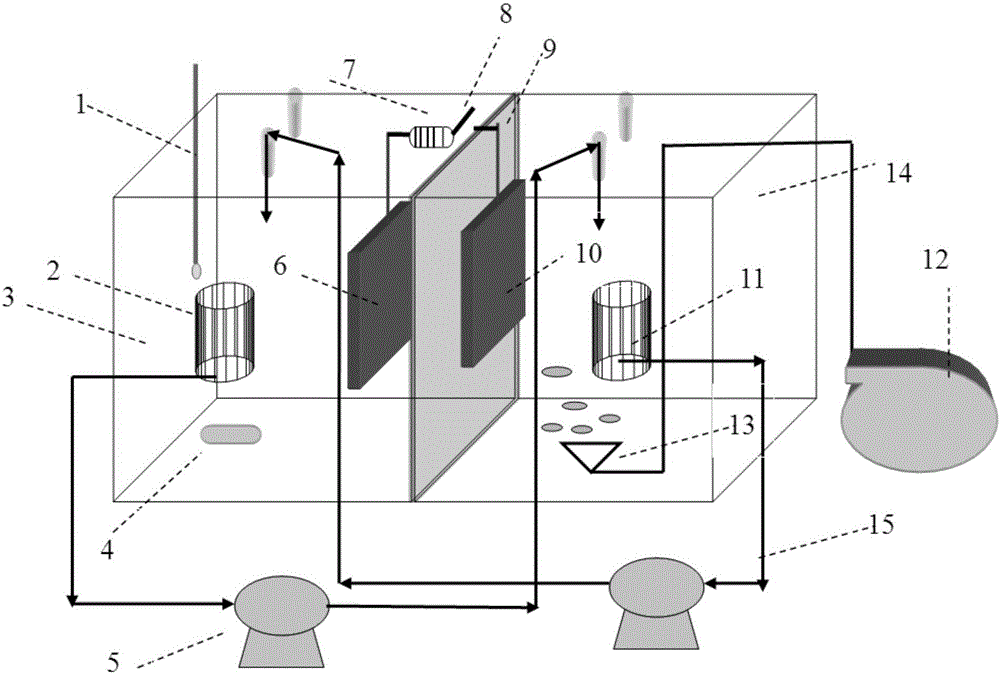

Method used

Image

Examples

Embodiment I

[0043] Embodiment I (1~3)

[0044] Type of waste water: Domestic sewage. According to the influent organic load, the hydraulic retention time and circulation flow rate are determined, so that the domestic sewage is circulated through the dynamic membrane in the anaerobic tank and the aerobic tank respectively to complete the degradation of anaerobic and aerobic microorganisms, and the different degradation times are measured. COD, SS, DO, pH value, temperature and other indicators of the water body in the pool.

Embodiment II

[0045] Embodiment II (1~3)

[0046] Wastewater type: printing and dyeing wastewater. According to the influent organic load, the hydraulic retention time and circulation flow rate are determined, so that the domestic sewage is circulated through the dynamic membrane in the anaerobic tank and the aerobic tank respectively to complete the degradation of anaerobic and aerobic microorganisms, and the different degradation times are measured. COD, SS, DO, pH value, temperature and other indicators of the water body in the pool.

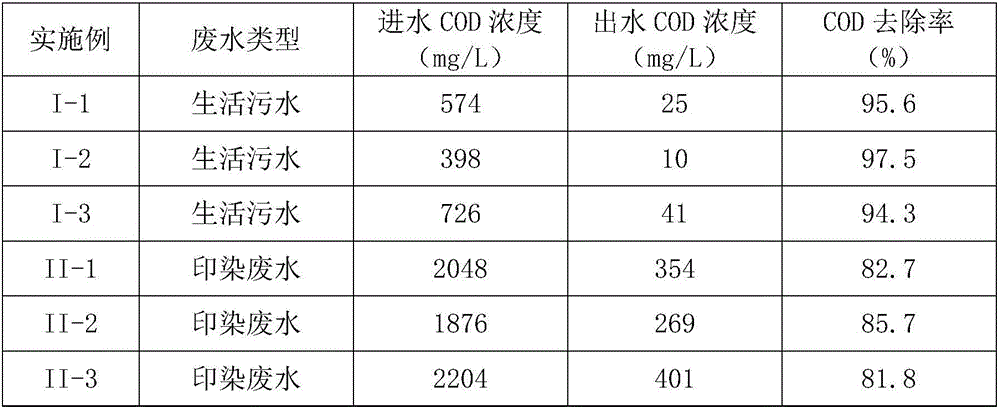

[0047] The domestic sewage and printing and dyeing wastewater treatment effects of Embodiment I and Embodiment II are shown in Table 1.

[0048] Table 1

[0049]

[0050] In order to realize the standard discharge of waste water, recycle electric energy and realize the effective utilization of resources, the present invention combines microbial fuel cell technology and dynamic membrane technology to realize the simultaneous degradation of pollutants i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com