A Manipulator System with High Controllability

A manipulator, highly advanced technology, applied in the field of manipulator system, achieves the effects of novel structure, simple structure and lightening the weight of the pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

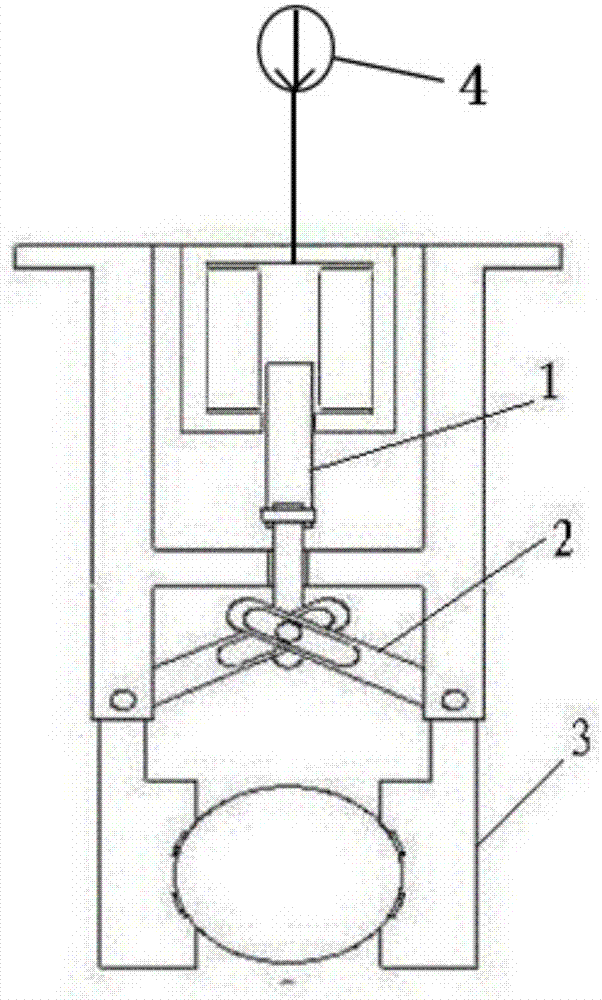

[0031] Such as figure 1 A manipulator system with a high degree of controllability is shown, including a driving part 1, a transmission part 2 and a finger part 3, the driving part 1 is connected through the transmission part 2 and drives the finger part 3, and the driving part 1 It is a hydraulic cylinder, and the finger part 3 includes at least two gripping mechanical fingers; the hydraulic cylinder is supplied with oil by an oil supply pump; the oil supply pump is a giant magnetostrictive pump 4 . The transmission part 2 is two mutually hinged plates. The two transmission parts 2 are provided with slide grooves. The end of the driving part 1 is connected with two transmission parts 2 at the same point. The transmission part 2 is two mutually hinged plates. The two transmission parts 2 are provided with slide grooves. The end of the driving part 1 is connected with two transmission parts 2 at the same point.

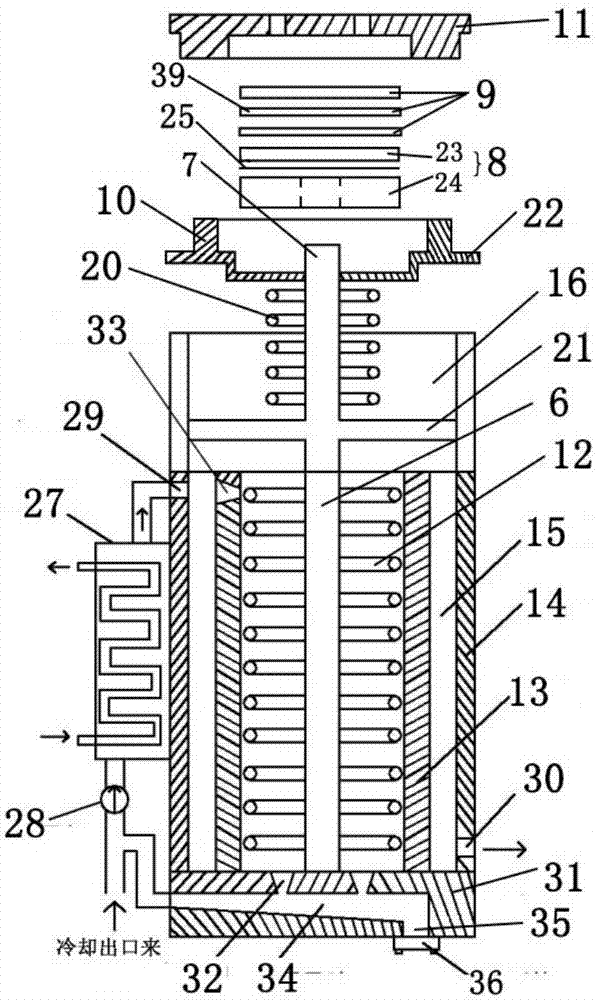

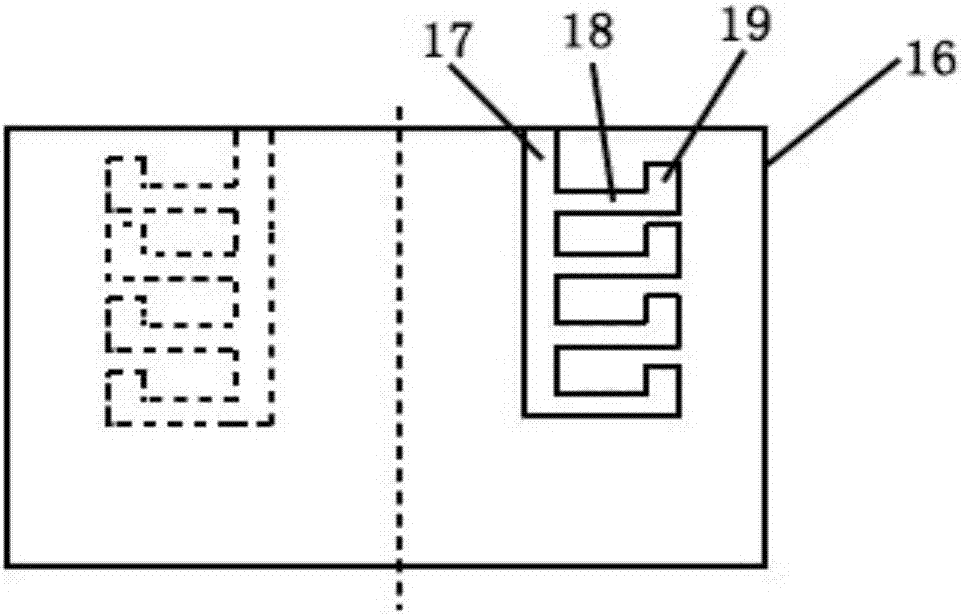

[0032] Such as figure 2 As shown, the giant magnetostricti...

Embodiment 2

[0042] Such as figure 1 A manipulator system with a high degree of controllability is shown, including a driving part 1, a transmission part 2 and a finger part 3, the driving part 1 is connected through the transmission part 2 and drives the finger part 3, and the driving part 1 It is a hydraulic cylinder, and the finger part 3 includes at least two gripping mechanical fingers; the hydraulic cylinder is supplied with oil by an oil supply pump; the oil supply pump is a giant magnetostrictive pump 4 . The transmission part 2 is two mutually hinged plates. The two transmission parts 2 are provided with slide grooves. The end of the driving part 1 is connected with two transmission parts 2 at the same point.

[0043] Such as figure 2 As shown, the giant magnetostrictive pump 4 is installed vertically as a whole, including a pump body, a giant magnetostrictive rod 6, an output shaft 7, a piston assembly 8, a one-way valve assembly 9, a pressure member 10, an end cover 11, and ...

Embodiment 3

[0053] Such as figure 1 A manipulator system with a high degree of controllability is shown, including a driving part 1, a transmission part 2 and a finger part 3, the driving part 1 is connected through the transmission part 2 and drives the finger part 3, and the driving part 1 It is a hydraulic cylinder, and the finger part 3 includes at least two gripping mechanical fingers; the hydraulic cylinder is supplied with oil by an oil supply pump; the oil supply pump is a giant magnetostrictive pump 4 . The transmission part 2 is two mutually hinged plates. The two transmission parts 2 are provided with slide grooves. The end of the driving part 1 is connected with two transmission parts 2 at the same point.

[0054] Such as figure 2 As shown, the giant magnetostrictive pump 4 is installed vertically as a whole, including a pump body, a giant magnetostrictive rod 6, an output shaft 7, a piston assembly 8, a one-way valve assembly 9, a pressure member 10, an end cover 11, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com