Polishing equipment for glass reinforced plastic pipe

A glass steel pipe and equipment technology, applied in the field of glass steel pipe grinding and polishing equipment, can solve the problems of the danger of polishing machines, high labor intensity, time-consuming and laborious, etc., and achieve the effects of high labor intensity, low production cost, and reasonable and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

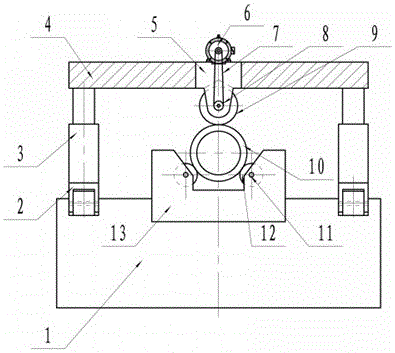

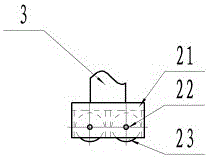

[0015] Such as figure 1 As shown, this specific embodiment adopts the following technical solutions: a glass steel pipe grinding and polishing equipment, including a base 1, a longitudinal movement mechanism 2, an oil cylinder 3, a beam 4, a polishing frame 5, a motor 6, a belt 7, and a driven pulley 8. Polishing wheel 9, glass steel pipe 10, connecting shaft 11, support wheel 12 and support frame 13; there are two longitudinal movement mechanisms 2, and the bottoms of the longitudinal movement mechanisms 2 are respectively movably connected to the left and right side guide grooves on the base 1 Among them, the upper side of the longitudinal moving mechanism 2 is fixedly connected with the oil cylinder 3; the two sides of the bottom of the beam 4 are respectively fixedly connected with the top of the oil cylinder 3; the polishing frame 5 is fixedly connected with the center of the beam 4; the motor 6 is fixedly connected At the top of the polishing frame 5; the polishing wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com