Bottled culture medium backwashing device

A culture medium and backwashing technology, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of medium infection, easy to breed mold, and affect the output and quality of edible fungus products, and achieve fixed Convenience and the effect of avoiding the threat of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

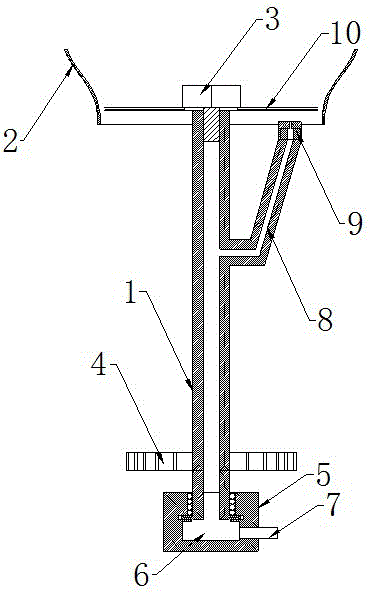

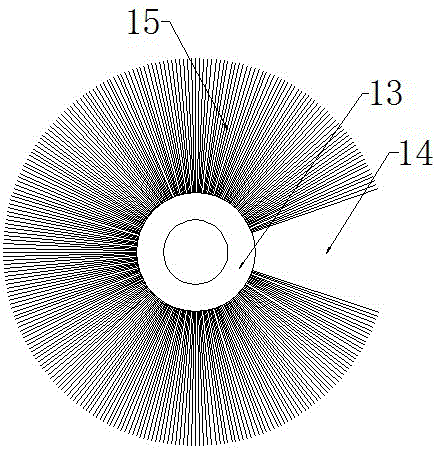

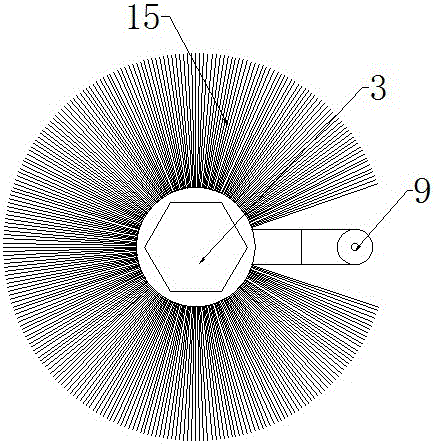

[0027] like figure 1 -Shown in -6: a bottled culture medium backwashing device, including a water supply pipe 1 and a culture medium bottle upside-down notch 2, and the culture medium bottle upside-down notch 2 includes an upper bottle body clamping section 11 and the lower bottle opening section 12, the upside-down notch 2 of the culture medium bottle is arranged on the upper part of the water supply pipe 1, and the water supply pipe 1 is vertically arranged with the ground as a reference plane, and the water supply pipe 1 The upper end of the pipe 1 is provided with an opening, which is blocked by a screw 3. The lower end of the water supply pipe 1 is provided with a transmission gear 4, and the lower end of the water supply pipe 1 is provided with a sealed bearing 5. The sealing A water storage chamber 6 is arranged inside the bearing 5, and a water inlet 7 is also arranged on the side wall of the sealed bearing 5, and the water inlet 7 communicates with the water storage c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com