Synthesis method of large-area two-dimensional composite nano-material

A composite nanomaterial and a synthesis method technology are applied in the field of synthesis of large-area two-dimensional composite nanomaterials, can solve problems such as influence on use, etc., and achieve the effects of simple operation, excellent photocatalytic degradation of organic matter and photocatalytic hydrogen production, and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for synthesizing large-area two-dimensional composite nanomaterials. First, thermally decompose amine precursors. The temperature of thermal decomposition is 400-700° C., and the heating time is 1-12 hours to synthesize C 3 N 4 nanosheets; the synthesized C 3 N 4 Nanosheets, amine solvents, cadmium salts, sulfur salts are mixed with water, stirred and ultrasonically dispersed to make them fully dispersed, heated and reacted, and centrifuged; the temperature of the heating reaction is 120-220°C, and the heating time is 6-6 48 hours; the rotational speed of the centrifuge is 100-14000 rpm until the pH of the product is neutral.

[0020] The mass volume ratio of the amine precursor to the amine solvent is 1 to 60:2 to 100; the volume ratio of the water to the amine solvent is 1:0.8 to 3; the added amount of the cadmium salt is 0.01 to 2.5 mol / L, the amount of sulfur salt added is 0.01~2.5mol / L.

[0021] The amine precursor is one or more combinations of melami...

Embodiment 2

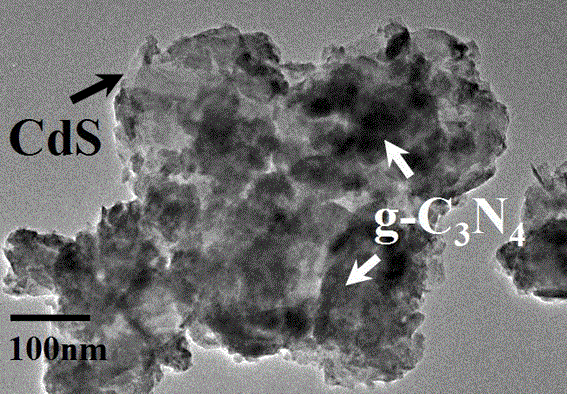

[0026] 30g of melamine was heated and decomposed at 600°C for 4 hours to synthesize C 3 N 4 nanosheets; then the C 3 N 4 Nanosheets, 20mL diethylenetriamine, 0.05mol / L cadmium nitrate, 0.05mol / L sulfur powder and 20mL water were mixed, stirred for 30 minutes, ultrasonicated for 30 minutes to fully disperse, heated at 150°C for 10 hours, and centrifuged to obtain Large-area two-dimensional composite nanomaterials.

[0027] Its TEM spectrum is as figure 1 As shown, the hydrogen production can reach 123 μmol each time the total volume of the system is 10ml.

Embodiment 3

[0029] Heat and decompose 50g of urea at 550℃ for 6 hours to synthesize 3 N 4 nanosheets; then the C 3 N 4 Nanosheets, 30mL triethylenetetramine, 0.1mol / L cadmium nitrate, 0.15mol / L dithizone and 10mL water were mixed, stirred for 30 minutes, ultrasonicated for 50 minutes to fully disperse, heated at 160°C for 12 hours, centrifuged Obtain large-area two-dimensional composite nanomaterials.

[0030] The hydrogen production can reach 148 μmol each time based on the total volume of the system being 10ml.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com