Soldering tin smoke purifier

A purifier and flue gas technology, applied in chemical instruments and methods, welding equipment, auxiliary devices, etc., can solve the problems of poor air permeability of filters, limited adsorption capacity, discounted adsorption effect, etc., and achieve small airflow resistance and strong absorption capacity. , high purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

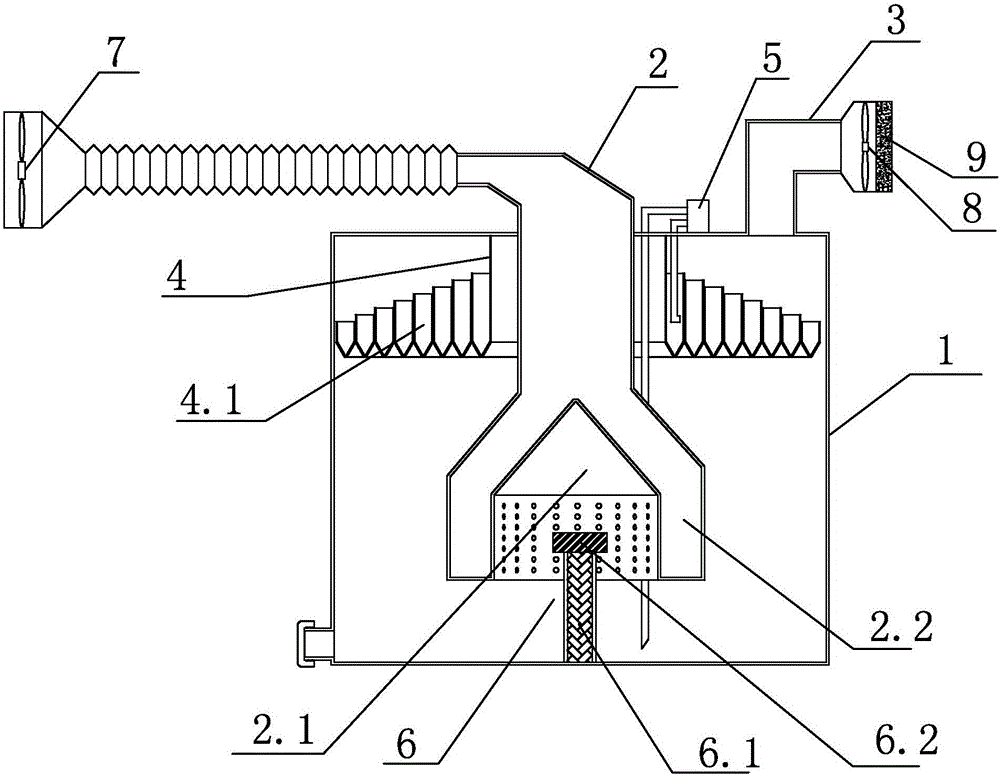

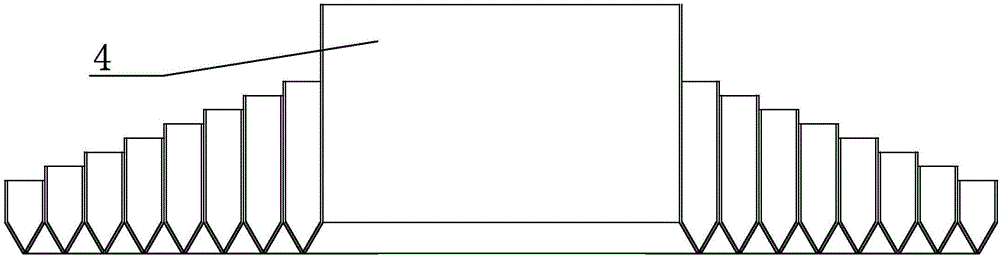

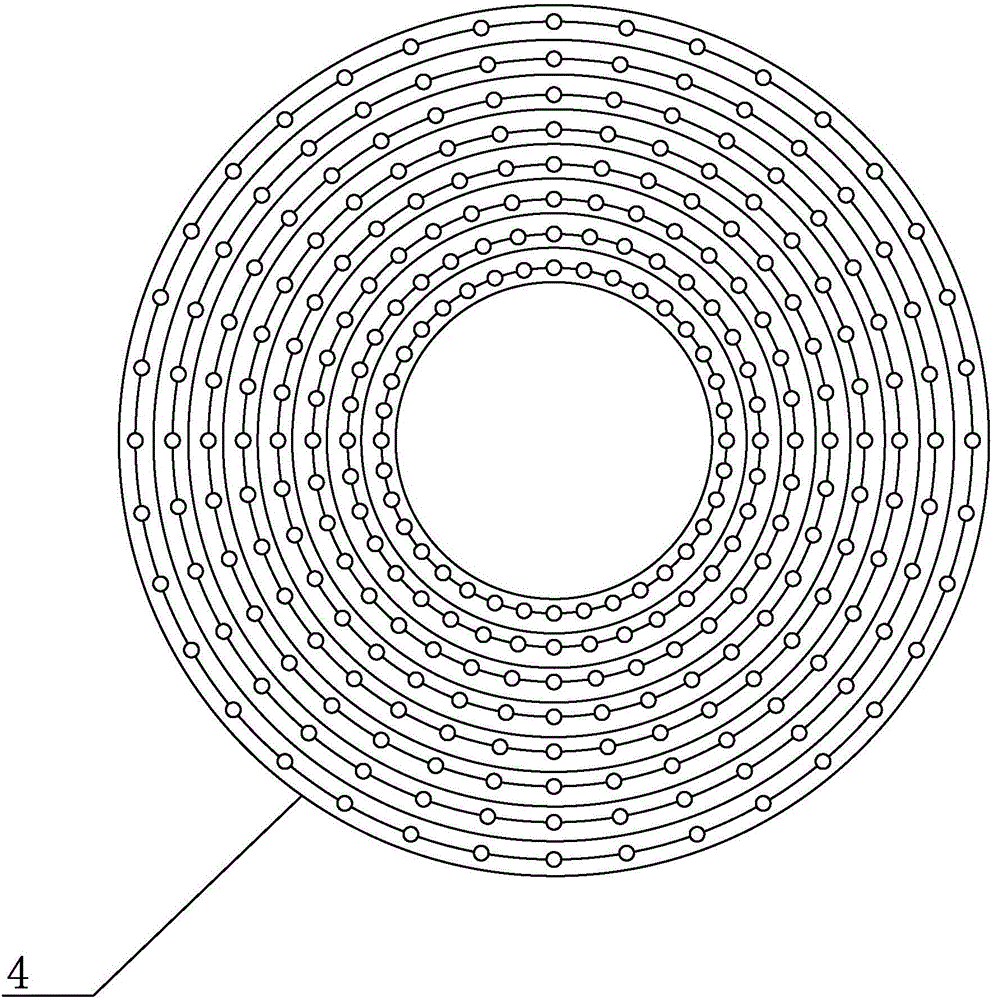

[0022] Such as Figure 1-4 As shown, a solder fume purifier includes a purification box 1, an air inlet pipe 2 extending through the top plate of the purification box 1 into its interior, and an exhaust pipe 3 communicated with the purification box 1; The outer wall of the trachea 2 is sealed and connected with the top plate of the purification box 1; the end surface of the air outlet of the air inlet pipe 2 is concaved into a cavity 2.1, and the outer wall of the air inlet pipe 2 surrounds the wall of the cavity 2.1 to form a cavity. cavity 2.2; the cavity wall of the concave cavity 2.1 is provided with some exhaust holes; the top plate of the purification box 1 is provided with a liquid distributor 4 and is used to pump the liquid at the bottom of the purification box 1 into the liquid The water pump 5 of the distributor 4; the bottom of the liquid distributor 4 is provided with a number of drain holes distributed along the circumference of the inlet pipe 2; the cavity 2.1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com