Hull breaking machine for astragalus sinicus seeds and operating method thereof

A technology of vetch seeds and shell breaker, which is applied in the directions of seed and rhizome treatment, cleaning methods and utensils, chemical instruments and methods, etc. problems, to achieve the effect of improving shell breaking efficiency, improving germination rate and improving germination quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

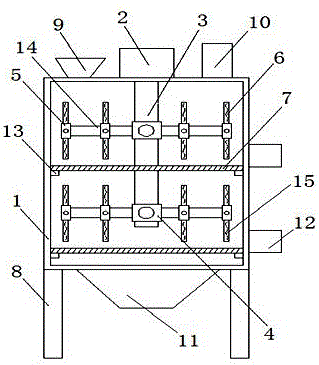

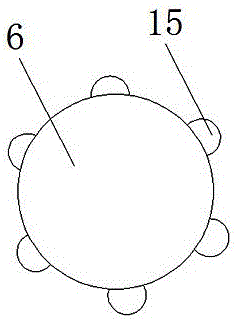

[0020] as attached figure 1 , 2 Shown in and 3, a shell breaking machine of milk vetch seeds comprises shell breaking chamber 1, motor 2, rotating shaft 3, mounting block 4, positioning block 5, stirring 6 bars and vibrating screen 7, is characterized in that: The shell breaking chamber 1 described above is arranged on the bracket 8, and the shell breaking room 1 is provided with a feed inlet 9, a dust outlet 10, a miscellaneous outlet 11, and a material outlet 12, and the shell breaking chamber 1 inner wall is provided with The vibration motor 13 can discharge the dust produced in the shell breaking process of milk vetch seeds through the dust outlet 10 from the shell breaking chamber 1, and the unsaturated milk vetch seeds can be discharged from the shell breaking room 1 through the miscellaneous outlet 11, thereby It can improve the cleanliness of milk vetch seeds after shell breaking, the motor 2 is arranged on the outer wall of the shell breaking room 1, the rotating sha...

Embodiment 2

[0026] as attached figure 1 , 2 Shown in and 4, a shell breaking machine of milk vetch seeds comprises shell breaking chamber 1, motor 2, rotating shaft 3, mounting block 4, positioning block 5, stirring 6 bars and vibrating screen 7, is characterized in that: all The shell breaking chamber 1 described above is arranged on the bracket 8, and the shell breaking room 1 is provided with a feed inlet 9, a dust outlet 10, a miscellaneous outlet 11, and a material outlet 12, and the shell breaking chamber 1 inner wall is provided with The vibration motor 13 can discharge the dust produced in the shell breaking process of milk vetch seeds through the dust outlet 10 from the shell breaking chamber 1, and the unsaturated milk vetch seeds can be discharged from the shell breaking room 1 through the miscellaneous outlet 11, thereby It can improve the cleanliness of milk vetch seeds after shell breaking, the motor 2 is arranged on the outer wall of the shell breaking room 1, the rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com