Walnut shell crushing machine

A shell breaking machine and walnut technology, applied in the fields of shelling, pod removal, food science, etc., can solve problems such as difficult to control the force and angle of knocking, reduce labor intensity, broken nuts and shells, etc., to achieve convenience and popularization. application, reduce labor intensity, and facilitate operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

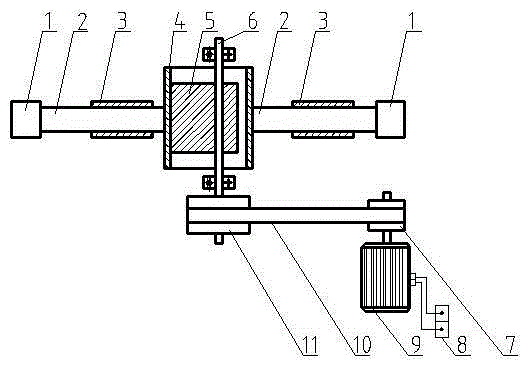

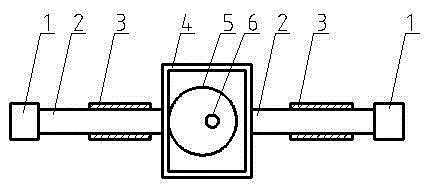

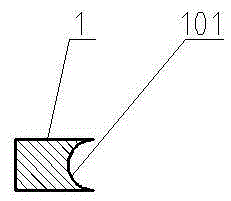

[0014] see Figure 1~Figure 3 The machine is composed of a motor, a power transmission device, an eccentric roller mechanism, a guiding device and a shell breaking device. When the switch (8) is closed and energized, the motor (9) rotates, the driving pulley (7) transmits power to the driven pulley (11) through the timing belt (10), and drives the eccentric roller (5) to rotate through the rotating shaft (6) , when the big end side of the eccentric roller (5) contacts the left side plate of the baffle box (4), the hammer (1) is connected with the baffle box (4) through the connecting rod (2), and the guide sleeve ( 3) Move to the left under the action to break the walnut shell. At this time, fill in the right part of the device; when the big end side of the eccentric roller (5) contacts the right side plate of the baffle box (4), the guide sleeve ( 3) Under the action, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com