Negative electrode material for lithium battery and preparation method of negative electrode material

A negative electrode material, lithium battery technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of not having sufficient mechanical strength, porous silicon is difficult to coat, and is easy to be damaged, and achieves excellent cycle stability and rate Performance, improvement of interface contact performance, effect of suppressing volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A preparation method of a negative electrode material for a lithium battery, comprising the steps of:

[0029] (a) adding nanoporous silicon into nitric acid with a concentration of 16 mol / L, and stirring until completely dissolved to obtain a nanoporous silicon solution;

[0030] (b) adding nano-graphene and sodium lignosulfonate into water, and stirring until the nano-graphene is completely dissolved to obtain a nano-graphene solution;

[0031] (c) Add 0.1mol / L NaOH solution to neutralize nitric acid in the nanoporous silicon solution, and gradually add until no precipitation occurs;

[0032] (d) filtering and washing the precipitate in step (c) to neutrality, and then adding it to the graphene nano-solution in step (b), and oscillating with ultrasonic waves to completely disperse the precipitate in the graphene nano-solution to obtain mixture;

[0033] (e) Heat the mixed solution to 80°C for 2 hours, then lower it to room temperature, add 10% hydrochloric acid to t...

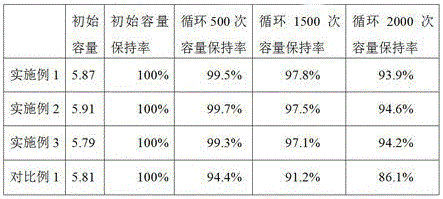

Embodiment 1

[0045] The lithium battery negative electrode material in this embodiment has a three-layer structure: the inner layer is nanoporous silicon, the outer layer is nanographene, and the middle layer is graphite. Among them, the nanoporous silicon has a particle size of 100nm and a pore size of 25nm; the nanographene has a particle size of 3nm; and the graphite is sintered graphite.

[0046] A preparation method of lithium battery negative electrode material is as follows:

[0047] (a) adding nanoporous silicon into nitric acid with a concentration of 16 mol / L, and stirring until completely dissolved to obtain a nanoporous silicon solution;

[0048](b) adding nano-graphene and sodium lignosulfonate into water, and stirring until the nano-graphene is completely dissolved to obtain a nano-graphene solution;

[0049] (c) Add 0.1mol / L NaOH solution to neutralize nitric acid in the nanoporous silicon solution, and gradually add until no precipitation occurs;

[0050] (d) filtering an...

Embodiment 2

[0054] The lithium battery negative electrode material in this embodiment has a three-layer structure: the inner layer is nanoporous silicon, the outer layer is nanographene, and the middle layer is graphite. The nanoporous silicon has a particle size of 200nm and a pore size of 35nm; the nanographene has a particle size of 8nm; and the graphite is sintered graphite.

[0055] A preparation method of lithium battery negative electrode material is as follows:

[0056] (a) adding nanoporous silicon into nitric acid with a concentration of 16 mol / L, and stirring until completely dissolved to obtain a nanoporous silicon solution;

[0057] (b) adding nano-graphene and sodium lignosulfonate into water, and stirring until the nano-graphene is completely dissolved to obtain a nano-graphene solution;

[0058] (c) Add 0.1mol / L NaOH solution to neutralize nitric acid in the nanoporous silicon solution, and gradually add until no precipitation occurs;

[0059] (d) filtering and washing t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com