Tape coiling type intelligent card module SMD packaging structure and manufacturing method thereof

A chip packaging and manufacturing method technology, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., to achieve the effects of thin products, good heat dissipation, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation of the tape and reel smart card module patch packaging structure and manufacturing method provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

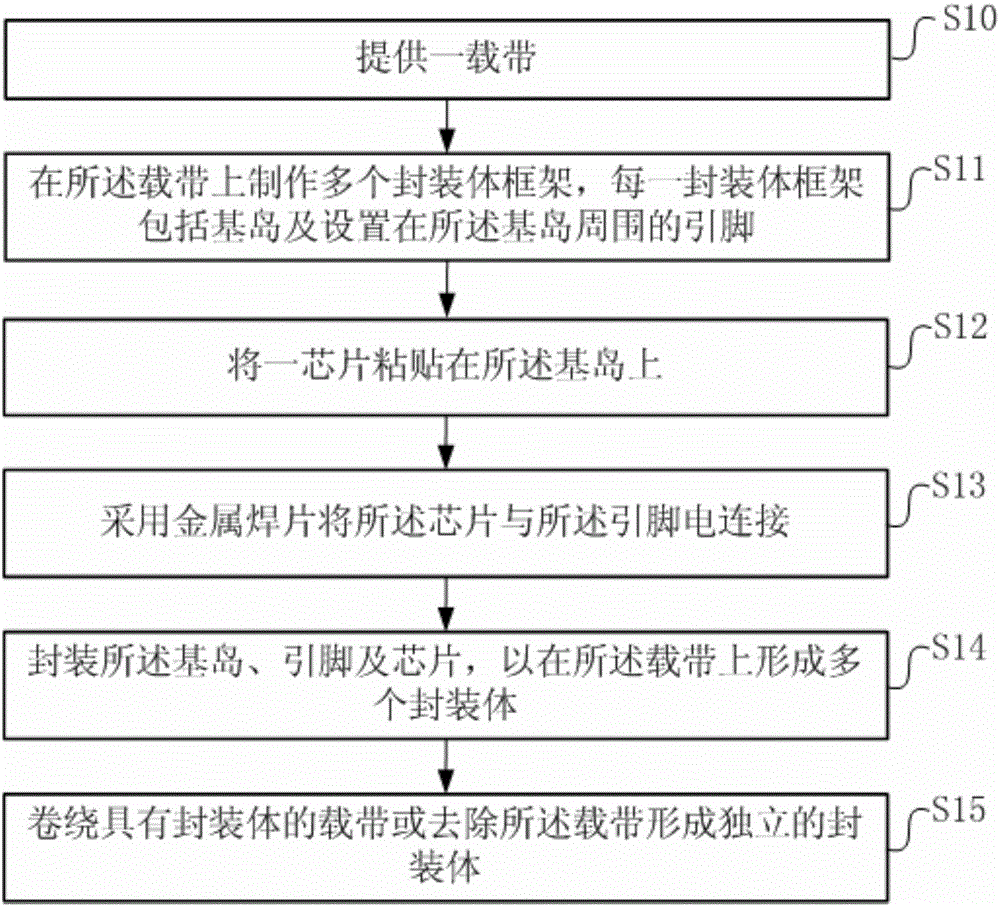

[0028] see figure 1 The manufacturing method of the tape-and-reel smart card module patch packaging structure of the present invention includes the following steps: step S10, providing a carrier tape; step S11, making a plurality of package frames on the carrier tape, each package frame including a base island and the pins arranged around the base island; step S12, paste a chip on the base island; step S13, use metal soldering pieces to electrically connect the chip to the pins; step S14, package the The base island, pins and chips are described to form a plurality of packages on the carrier tape; step S15, winding the carrier tape with the packages or removing the carrier tape to form an independent package.

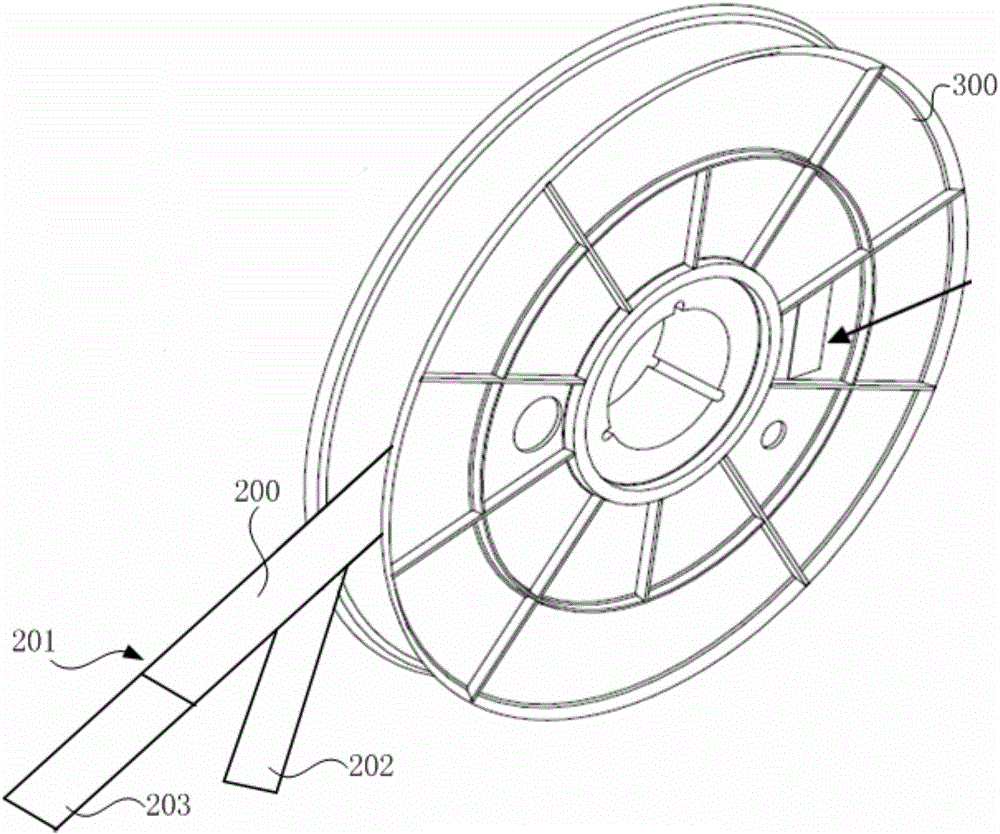

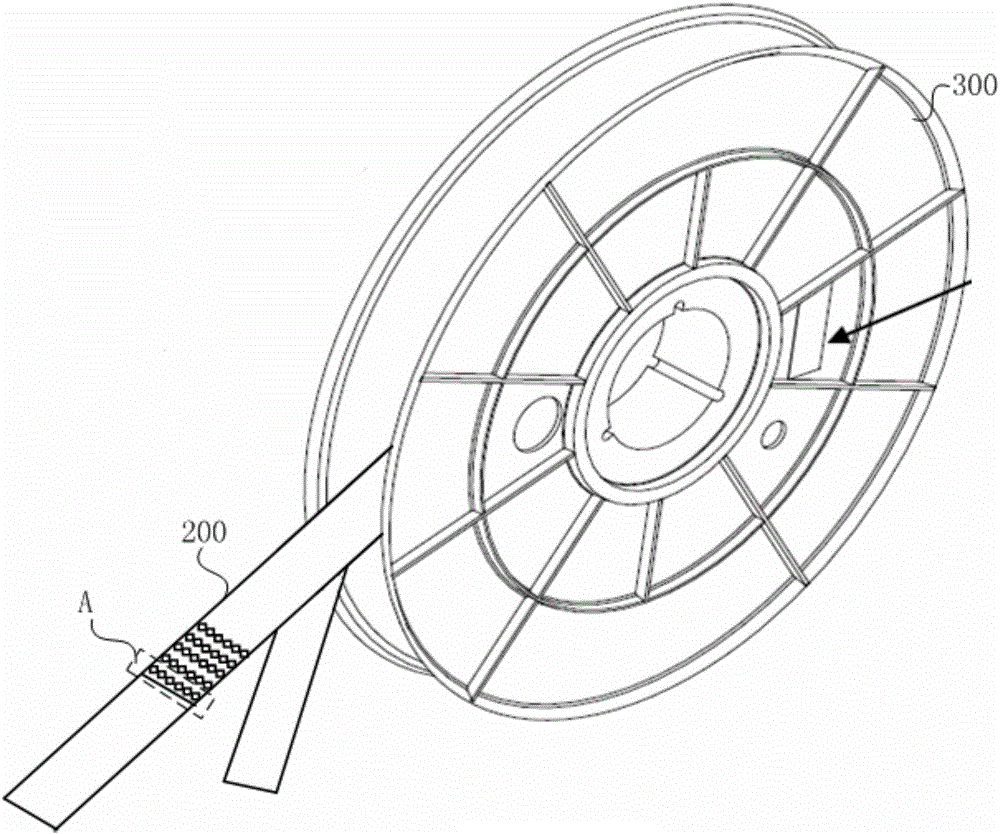

[0029] Figure 2A ~ Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com