Tobacco moisture retention performance test method

A moisture retention performance and testing method technology, applied in the field of tobacco, can solve the problem that the test and evaluation of tobacco moisture retention performance cannot take into account thermodynamics and kinetics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

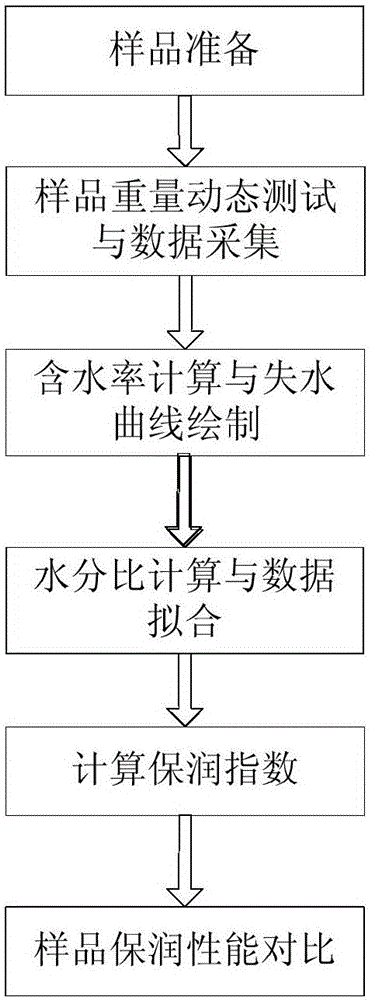

Method used

Image

Examples

Embodiment 1

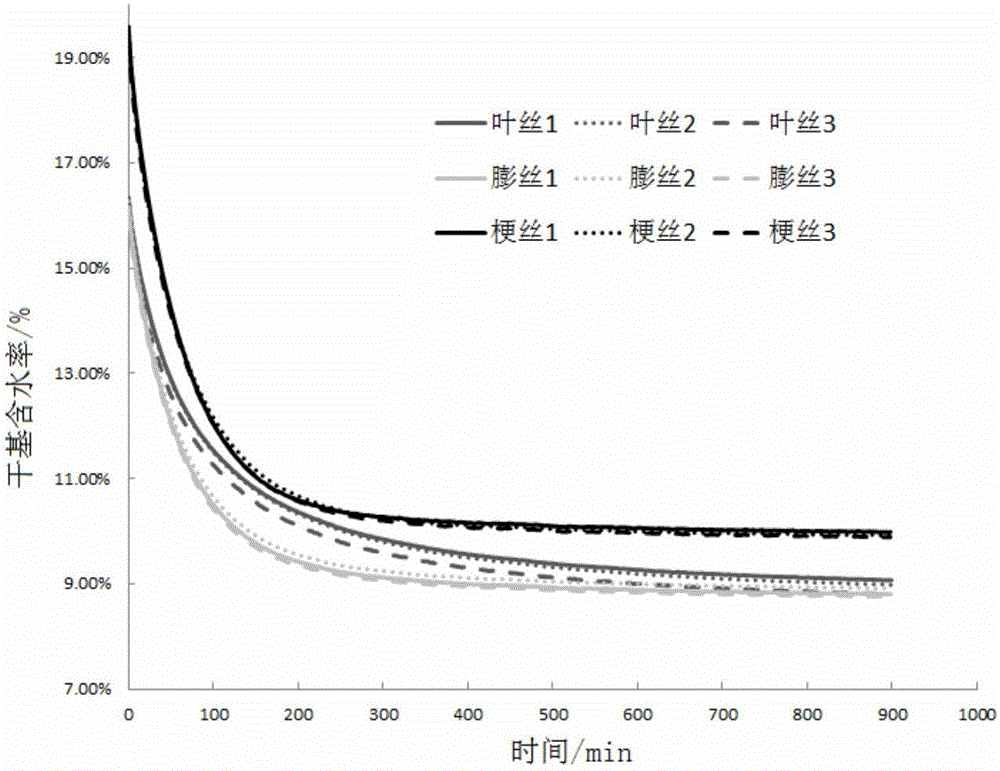

[0048] 1) Sample preparation: Weigh 12g of tobacco samples respectively and place them in sample dishes of known quality. The names and serial numbers of the tobacco samples are as shown in Table 1;

[0049] Table 1 Name list of tobacco samples

[0050] serial number

Tobacco sample name

1

leaf silk 1

2

leaf silk 2

3

leaf silk 3

4

Bulk 1

5

Bulk 2

6

Bulk 3

7

shredded stem 1

8

Shredded stem 2

9

Shredded stem 3

[0051] 2) The tobacco sample is equilibrated for 48 hours in a standard environment; the standard environment is RH=60%, T=22°C;

[0052] 3) Dynamic test of moisture content on dry basis: pre-set the temperature and relative humidity of the air environment in the dynamic moisture analysis climate box to 22°C and 40% respectively, and set the sample mass to be recorded every 20s, with the mass accurate to 0.0001g; After entering 9 tobacco samples, it starts to run a...

Embodiment 2

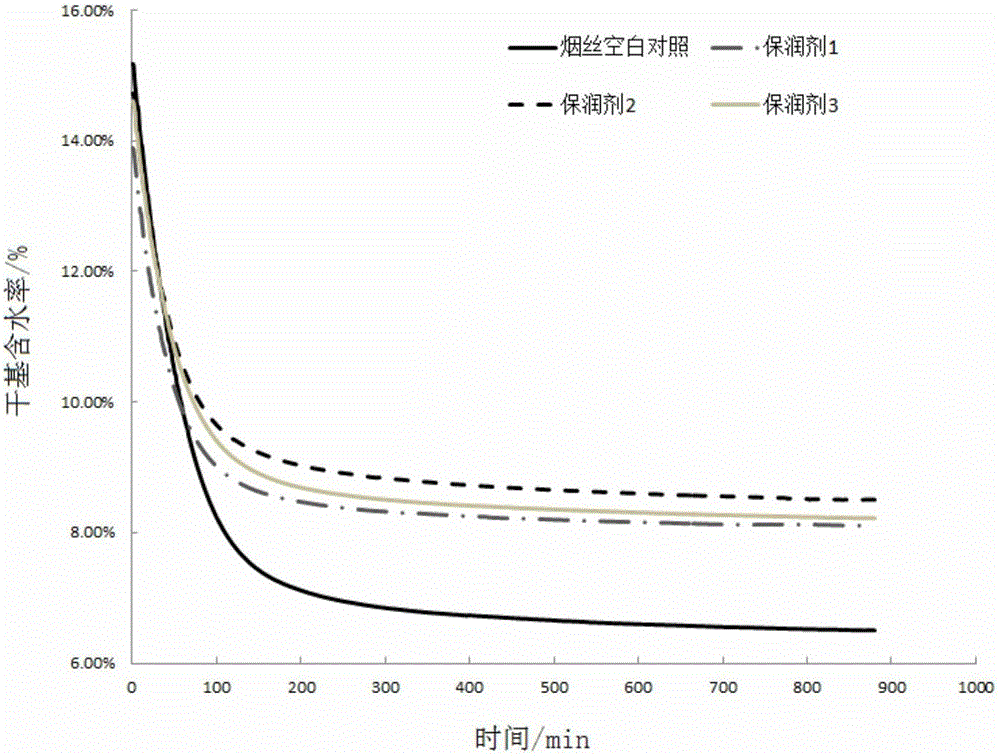

[0058] 1) Sample preparation: Weigh 1g shredded tobacco blank control sample and shredded tobacco sample added with different humectants and place them in a sample dish of known quality to test one by one. The names and serial numbers of the tobacco samples are shown in Table 3;

[0059] Table 3 Name list of tobacco samples

[0060] serial number

Tobacco sample name

1

Tobacco blank control

2

Tobacco + humectant 1

3

Tobacco + humectant 2

4

Tobacco + humectant 3

[0061] 2) The tobacco sample is equilibrated for 48 hours in a standard environment; the standard environment is RH=60%, T=22°C.

[0062] 3) Dynamic test of moisture content on a dry basis: set the temperature and relative humidity of the dynamic moisture tester (DVS) to 22°C and 30% respectively, record the sample mass every 1 minute, the mass is accurate to 0.000001g, and automatically stop and enter the drying process after 15 hours of operation program, get...

Embodiment 3

[0068] 1) Sample preparation: Weigh 10 g of cut stem blank control sample and cut stem sample with humectant added and place them in a sample dish of known quality. The names and serial numbers of the tobacco samples are shown in Table 5;

[0069] Table 5 Name list of tobacco samples

[0070] serial number

Tobacco sample name

1

Shredded stem blank control

2

Shredded stem + moisturizer 1

3

Shredded stem + moisturizer 2

4

Shredded stem + moisturizer 3

[0071] 2) Tobacco samples were equilibrated for 48 hours in a standard environment;

[0072] 3) Dynamic test of moisture content on a dry basis: pre-set the temperature and relative humidity of the air environment in the climate box to 22°C and 40% respectively, and set the sample mass to be recorded every 20s, with the mass accurate to 0.0001g; put 4 tobaccos in sequence Start running after the sample, and stop automatically after running to 48h, and get the tobacco samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com