Construction method for mountable recyclable foundation pit drainage and protection system

A construction method and technology of protection system, applied in infrastructure engineering, excavation, construction, etc., can solve the problems of increased construction cost, long construction period, material waste, etc., to save manufacturing cost and time cost, save time cost, construction simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

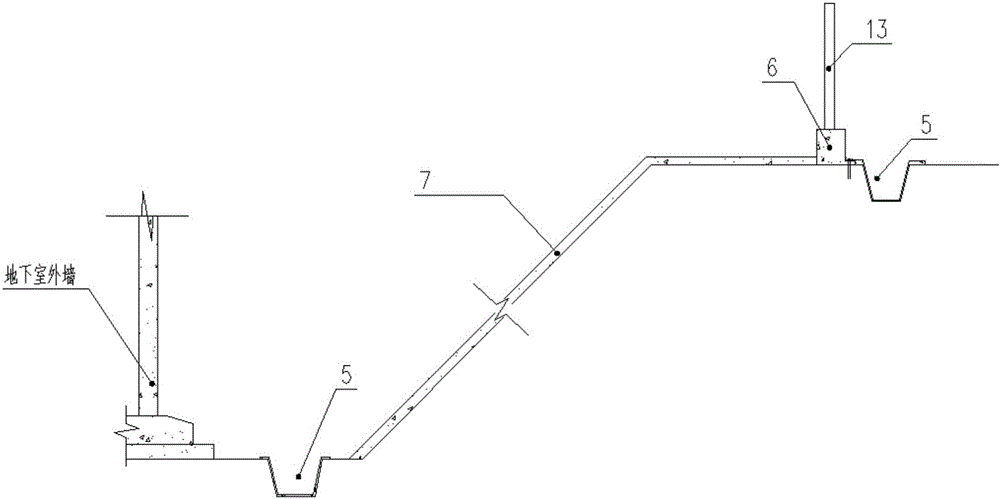

[0039] The water retaining wall 6 prefabricated in the factory is 300mm high, and the middle section of the drainage groove is in an inverted trapezoidal shape. The drainage groove and water retaining device prefabricated in the factory can realize the repeated utilization of the drainage groove and improve the utilization rate of materials; The drainage groove is an inverted trapezoid, the bottom width is 300mm, and the depth is 300mm. There are horizontal ends on both sides of the middle section of the drainage groove, such as Figure 4 and Figure 5 As shown, it is convenient to pick up and put down the drainage tank through the end, and at the same time, it is convenient to support the drainage tank and prolong the service life of the inverted trapezoidal drainage tank 10.

[0040] In the spliced drainage grooves, the bottom side of each drainage groove is horizontally provided with a second protrusion 12, and the other side is provided with a second groove 11, which is ...

Embodiment 2

[0051] The water retaining wall 6 is L-shaped, that is, the water retaining wall 6 includes a vertical section and a horizontal section, the adjacent water retaining walls 6 are coated with sealant, and the adjacent inverted trapezoidal drainage grooves 10 are evenly spaced. Coated with sealant to effectively ensure the sealing performance of the system and avoid leakage through the gap.

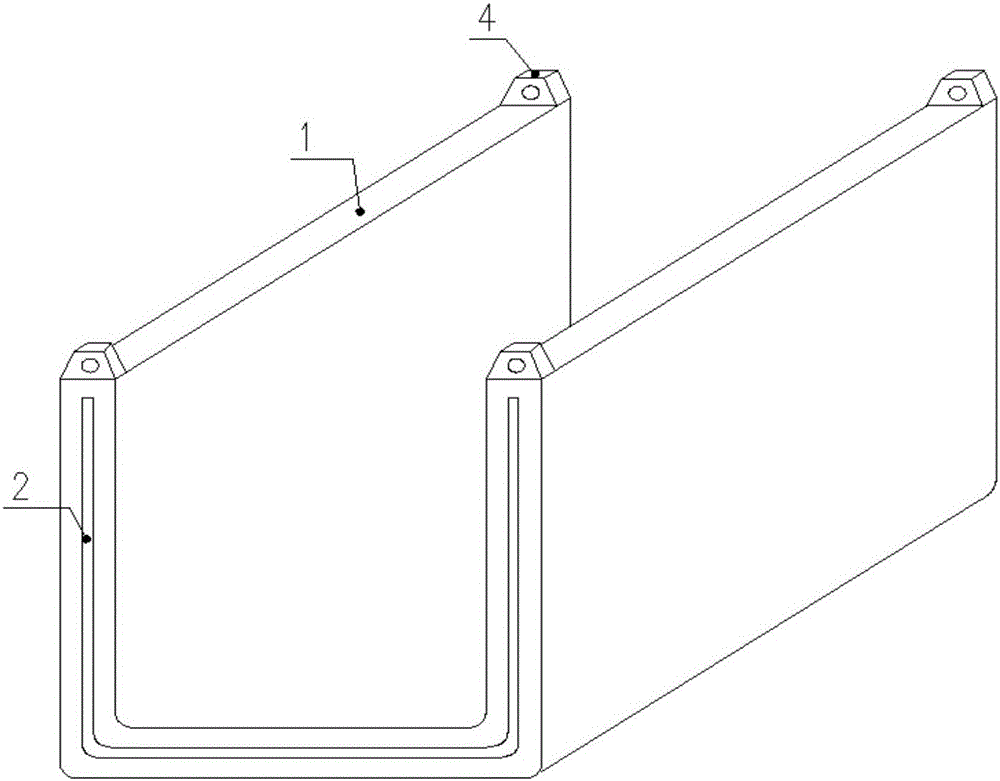

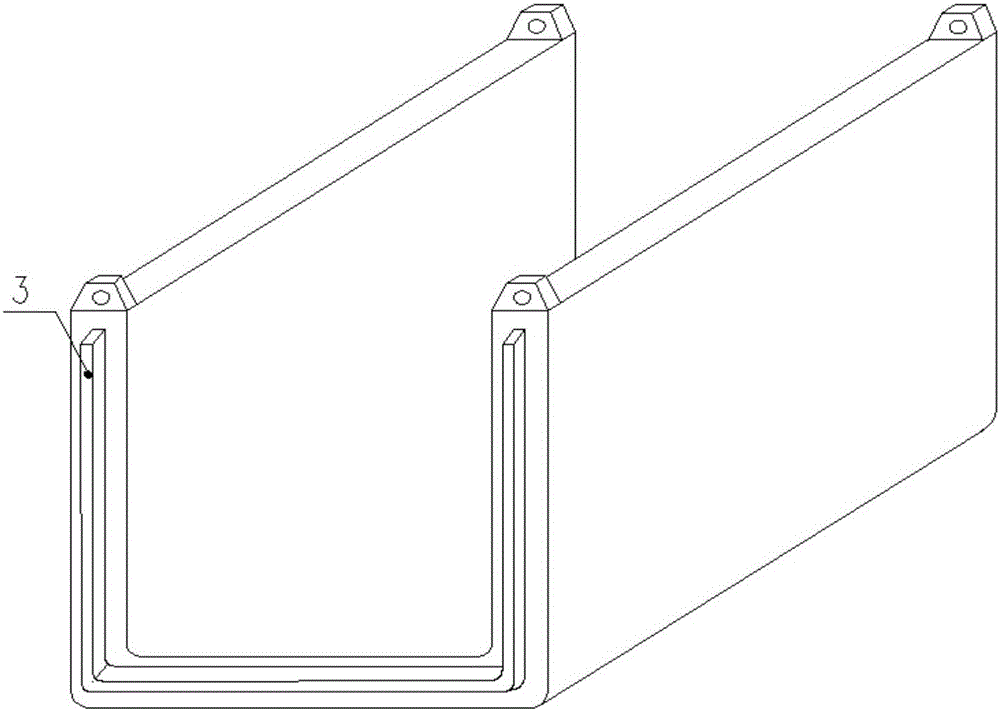

[0052] The middle section of the drainage groove is U-shaped, such as figure 2 and image 3 As shown, the two ends of each drainage groove in the spliced U-shaped drainage groove 1 are provided with a protrusion 3 at one end and a groove 2 at the other end. The setting of the protrusion 3 and the groove 2 not only further ensures rapid splicing , and can improve the sealing performance of the U-shaped drainage groove 1; the top four corners of the U-shaped drainage groove 1 are provided with connecting parts 4, and the adjacent U-shaped drainage grooves 1 are connected to each other thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com