Chlorine fastness improver, and preparation method and application thereof

A booster and chlorine-resistant technology, which is applied in the field of textile dyeing and finishing, can solve the problems of fabric hand feeling and shade negative impact, fabric color change, and poor washability, etc., to improve chlorine color fastness, fabric color change, Good washing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

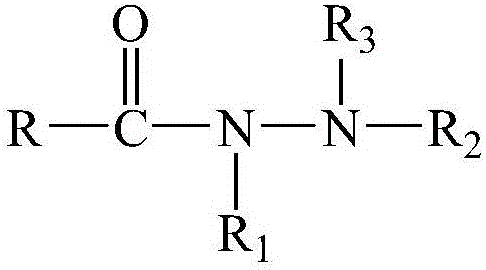

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1, preparation and application of chlorine-resistant promotion agent

[0053] 1. Preparation

[0054] Add 2 parts of sodium dodecylbenzenesulfonate to 81 parts of deionized water, stir and dissolve, then add 15 parts of dodecyl dicarboxylic acid dihydrazide, stir evenly, then transfer to a sand mill, and use 600 Sanding at a speed of rev / min for 10 hours, then adding 2 parts of polyacrylate, stirring at a speed of 150 rev / min for 2 hours. After discharging, the chlorine-resistant enhancer is obtained.

[0055] The appearance of the chlorine-resistant enhancer prepared in this example is: a milky white dispersion, which consists of: 2% polyacrylate, 15% hydrazide derivatives, 2% dispersant, and 81% deionized water.

[0056] 2. Application

[0057] Continue dyeing and finishing the chlorine-resistant enhancer nylon and spandex swimsuit fabric prepared above, the steps are as follows:

[0058] (1) padding: the chlorine-resistant promoting agent prepared by t...

Embodiment 2

[0060] Embodiment 2, the preparation and application of chlorine resistance promoting agent

[0061] 1. Preparation

[0062] Mix 1 part of dispersant NNO, 6 parts of isonicotinic acid hydrazide and 10 parts of suberic acid dihydrazide, and then add 1 part of fatty alcohol polyoxyethylene ether [C 13 h 27 (CH 2 CH 2 O) 9 H] and 79.5 parts of deionized water solution, after stirring evenly, then transferred to a sand mill, sanded at a speed of 800 rpm for 8 hours, then added 2.5 parts of polyacrylate, at a speed of 100 rpm Stir at speed for 3 hours. After discharging, the chlorine-resistant enhancer is obtained.

[0063] The appearance of the chlorine-resistant enhancer prepared in this example is: a milky yellow dispersion liquid, and its composition is: 2.5% of polyacrylate, 16% of hydrazide derivatives, 2% of dispersant, and 79.5% of deionized water.

[0064] 2. Application

[0065] Continue dyeing and finishing the chlorine-resistant enhancer nylon and spandex swimsu...

Embodiment 3

[0068] Embodiment 3, the preparation and application of chlorine resistance promoting agent

[0069] 1. Preparation

[0070] Add 0.5 parts of fatty alcohol polyoxyethyl ether sodium sulfate and 2.5 parts of coconut oil fatty acid diethanolamide into 78 parts of deionized water, stir and dissolve, then add 5 parts of azelaic acid dihydrazide and 13 parts of isophthalic dihydrazide, After stirring evenly, it was transferred to a sand mill and sanded at a speed of 400 rpm for 20 hours, then 1.5 parts of polyacrylate was added and stirred for 1.5 hours at a speed of 200 rpm. After discharging, the chlorine-resistant enhancer is obtained.

[0071] The appearance of the chlorine-resistant enhancer prepared in this example is: a milky white dispersion, which consists of: 1.5% polyacrylate, 18% hydrazide derivatives, 2.5% dispersant, and 78% deionized water.

[0072] 2. Application

[0073] Continue dyeing and finishing the chlorine-resistant enhancer nylon and spandex swimsuit fab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com