Device and method for cultivating diatom

A culture device and culture method technology, applied in the field of microbiology, can solve the problems of unguaranteed quality, unstable physical and chemical factors, low biomass production, etc., and achieve the effect of saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] In this example, two kinds of benthic diatoms were cultured, that is, algae species one: Nitzschia sp., algae species two: Amphora coffeeeformis

[0057] Algae cultivation steps: use F / 2 medium to cultivate algae; culture at 30-38°C until the concentration of algae is 0.1g / L.

[0058] F / 2 medium adds the following elements per liter of seawater: NaNO 3 75mg,NaH 2 PO4·2H 2 O5.65mg, Na 2 EDTA 4.16mg, FeCl 3 ·6H 2 O 3.15mg, Na 2 SiO 3 9H 2 O 20mg, CuSO 4 ·5H 2 O 0.01mg, ZnSO 4 ·7H 2 O 0.022mg, CoCl 2 ·6H 2 O 0.01mg, MnCl 2 4H 2 O0.18mg, Na 2 MoO 4 2H 2 O 0.006mg, Vitamin B 12 0.0005mg, Vitamin B1 0.1mg, Biotin 0.0005mg.

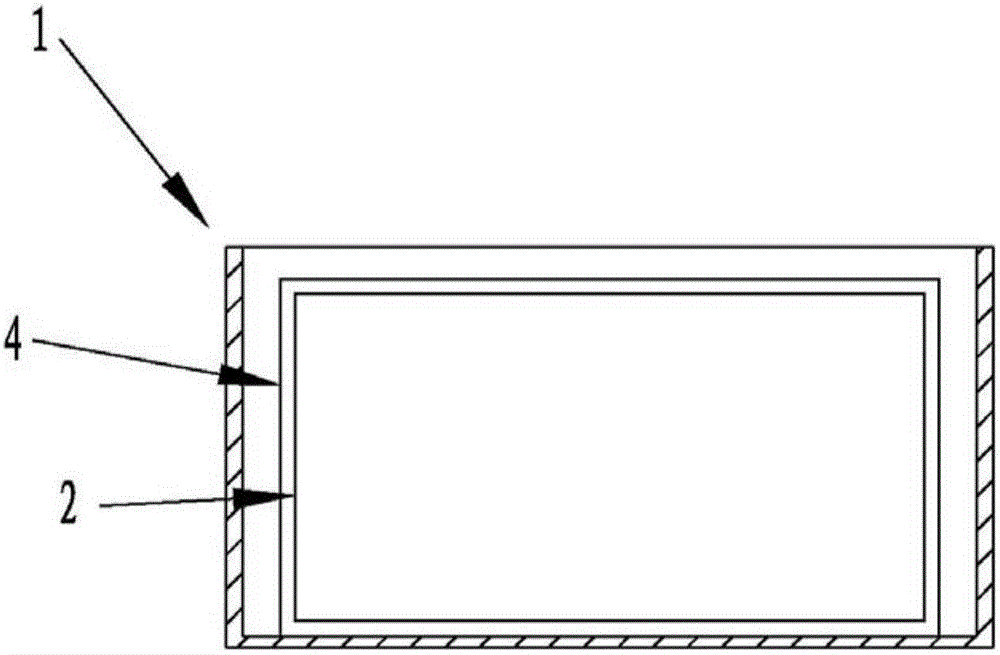

[0059] Large-scale cultivation steps: use a 50L translucent plastic box as a culture container, add 40L of F / 2 seawater medium into the container, pour 100mg (wet weight) of algae seeds into the medium, and put 40-80 mesh polyethylene yarn The net is fixed on the plastic frame to form a diatom attachment board for diatom attachment...

Embodiment 2

[0063] In this embodiment, culture experiments were carried out on Amphora coffeaeformis and Amphora exigua.

[0064] Algae cultivation steps: use F / 2 medium to cultivate algae; culture at 30-38°C until the concentration of algae is 0.1g / L.

[0065] Large-scale cultivation steps: Add 40 liters of F / 2 culture medium to a 50-liter culture container, the salinity of F / 2 culture medium is 35‰ to 55‰, and the algae cultured in the previous step are divided into the culture volume of the algae species and F / 2 The medium volume ratio is 1:100 and placed in the culture container, and the PC board is fixed on the plastic frame to form a diatom attachment plate for diatom attachment, and multiple diatom attachment plates are vertically placed on the attachment frame at intervals of 3 cm , blow air to the diatom attached plate, make the temperature of the seawater culture medium 35-38 ℃, irradiate the light on the diatom attached plate, the light intensity is 20μmol.m -2 .s -1 , so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com