Water-borne epoxy primer

A water-based epoxy and water-based epoxy resin technology, applied in the field of coatings, can solve the problems of zinc fume harmful to human health, zinc powder cannot be stored for a long time, zinc fever and other problems, and achieve excellent anti-corrosion performance, high mechanical strength and good adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

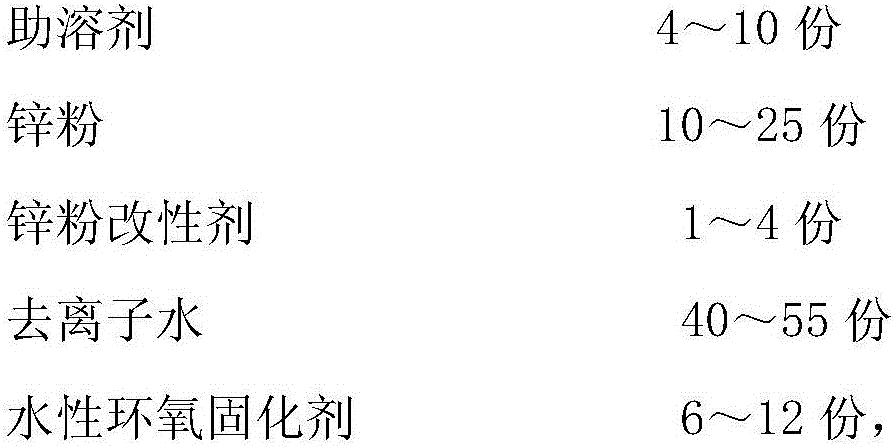

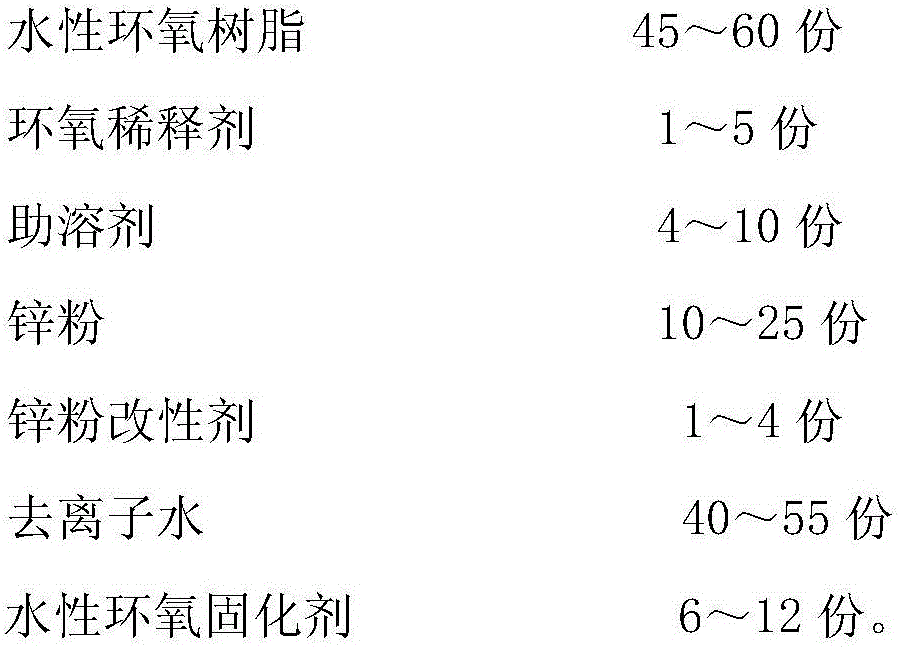

Method used

Image

Examples

Embodiment 1

[0026] (1) Modification of zinc powder

[0027] Add 0.8 kg of calix[6]arene and 0.1 kg of isophorone diisocyanate to 18 kg of dimethylformamide, mechanically stir and reflux for 4 hours, add 5 kg of nano-sized zinc powder to the above system, and continue to stir and reflux After 12 hours, the solvent was recovered, filtered, washed, dried, and pulverized to obtain modified zinc powder;

[0028] (2) 50 parts by weight of E-44 water-based epoxy resin, 4 parts by weight of AGE epoxy reactive diluent, and 7 parts by weight of propylene glycol methyl ether are fully mixed, then add the modified zinc powder 18 parts obtained in the step (1) wherein parts by weight, stirred at 65°C for 30 minutes to obtain component A;

[0029] (3) After fully mixing 9 parts by weight of the water-based epoxy curing agent and 50 parts by weight of deionized water, package it separately as component B.

[0030] After curing to form a film, the coating properties were tested as shown in Table 1.

Embodiment 2

[0032] (1) Modification of zinc powder

[0033] Add 1.0 kg of calix[8]arene and 0.1 kg of isophorone diisocyanate to 18 kg of dimethylformamide, mechanically stir and reflux for 4 hours, add 5 kg of nano-sized zinc powder to the above system, and continue to stir and reflux After 12 hours, the solvent was recovered, filtered, washed, dried, and pulverized to obtain modified zinc powder;

[0034] (2) with embodiment 1;

[0035] (3) with embodiment 1.

[0036] The film-forming process was the same as in Example 1, and the coating performance was tested as shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com