Moving chassis for indoor service robot

A service robot and mobile chassis technology, which is applied in the direction of motor vehicles, power units, electric power units, etc., can solve the problems of complex structure of multi-wheel chassis, easy detachment of driving wheels from the ground, poor moving stability, etc., and achieve filterability and passability The effect of lifting, smooth movement, good reliability and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

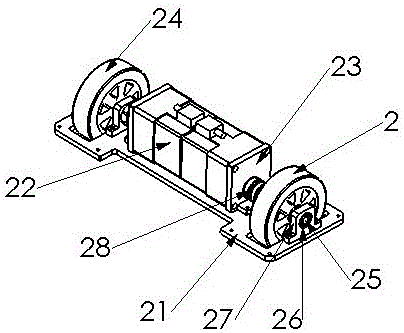

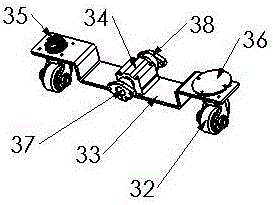

[0024] Such as Figure 1-5 As shown, a mobile chassis of an indoor service robot includes a base plate 1, a drive mechanism 2, a universal wheel mechanism 3, a sensing system 5, and a power supply system 6. The drive mechanism 2 includes a drive base plate 21, and two Group drive motor 22 and drive wheel 24, two groups of drive motors 22 and drive wheel 24 mirror image settings mutually; Universal wheel mechanism 3 comprises universal wheel base 31, is arranged on two groups of universal wheels 32, The universal wheel stays 33 fixedly connected to two sets of universal wheels 32, the universal wheel stays 33 are rotatably connected to the universal wheel base 31 through a linear bearing 34, and the upper surfaces of the two ends of the universal wheel stays 33 are respectively provided with a Spring 35, the upper end of spring 35 is fixedly provided with a spring pressure plate 36, and spring pressure plate 36 is fixed on the caster base 31; Sensing system 5 comprises navigati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com