Novel bucket washing brush

A bucket and bucket clamping technology, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as friction and scratches on the inner wall of the bucket, waste of manpower and material resources, and slow speed, so as to improve hygiene quality and save energy. The effect of manpower and material resources and fast cleaning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

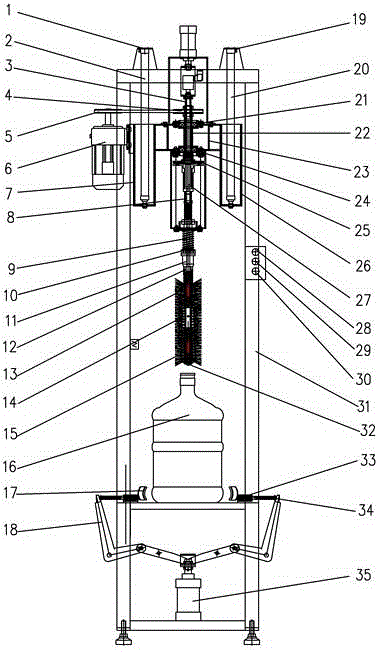

[0014] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , a new type of bucket washing brush, mainly composed of a bucket clamping device, a lifting device, a frame, a bucket brush and a rotating device, etc. It is characterized in that: the upper ends of the cylinders (2), (20) are respectively installed on the cylinder base (1), (19) The upper and lower ends are connected with the lifting bridge (7), (26), the upper end of the driving shaft fixing seat (23) is installed with the upper bearing seat of the driving shaft (21), and the lower end is installed with the lower bearing seat of the driving shaft (24). Both sides are respectively connected with the lifting bridge (7), (26), the lifting bridge (7) is connected with the motor (6), the belt pulley (5) is connected with the motor (6), and the driving shaft (22) is respectively installed on the upper and lower sides. The upper bearing seat (21) and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com