Floatation column intensified separation device with filler structure and separation method

A sorting device and flotation column technology, which is applied in flotation, solid separation, etc., can solve the problem of unstable separation index, and it is difficult to ensure the entrainment and return of uniform non-floatable mineral fine mud with the size of mineralized bubbles in the foam layer. Mixing and dissociation problems, to achieve uniform size, reduce back-mixing and entrainment, and improve the quality of concentrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

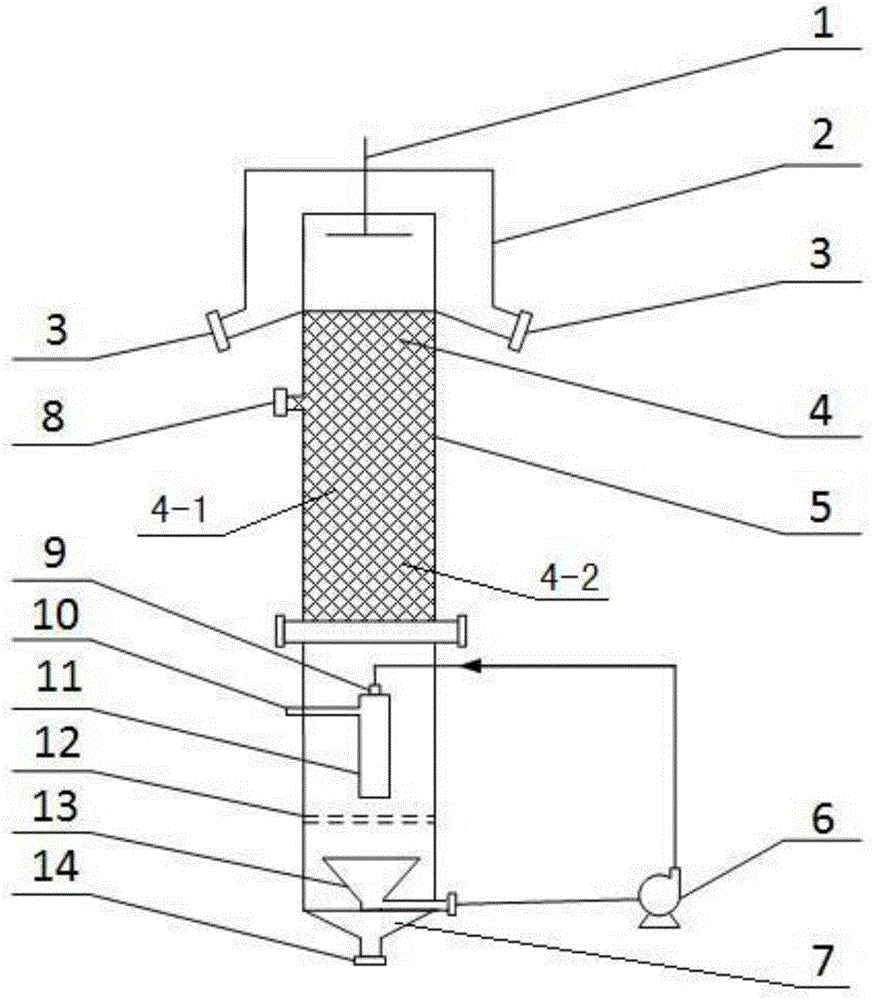

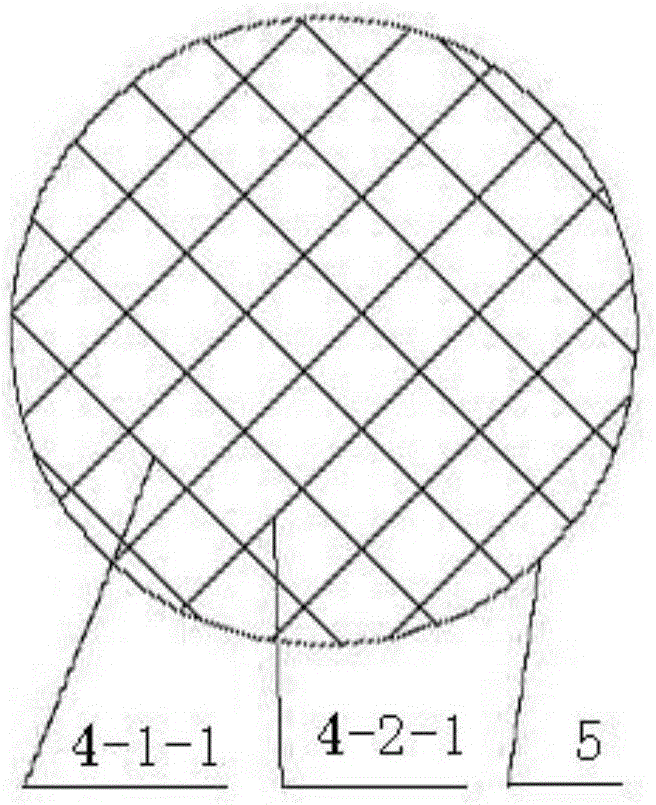

[0036] see Figure 1-Figure 2 , a flotation column enhanced separation device with a packing structure, including a hollow column 5, the top of the column 5 is provided with a foam collection device; the foam collection device includes a foam collection tank 2, a spray device 1 and a concentrate pipe 3 , the foam collection tank 2 is arranged on the top of the cylinder 5, the spray device 1 is arranged on the upper part of the foam collection tank 2, and the concentrate pipe 3 is arranged on the side of the foam collection tank 2;

[0037] In the cylinder 5, there are packing 4, medium ore mineralization pipe 11, sieve plate 12, and medium ore collecting funnel 13 in order from top to bottom; at the bottom of the cylinder 5, there is a discharge port connected with the tailings pipe 14 7. The filler 4 is located at the upper part of the column body 5, and the medium ore mineralization pipe 11, the sieve plate 12, and the medium ore collection funnel 13 are located at the lower...

Embodiment 2

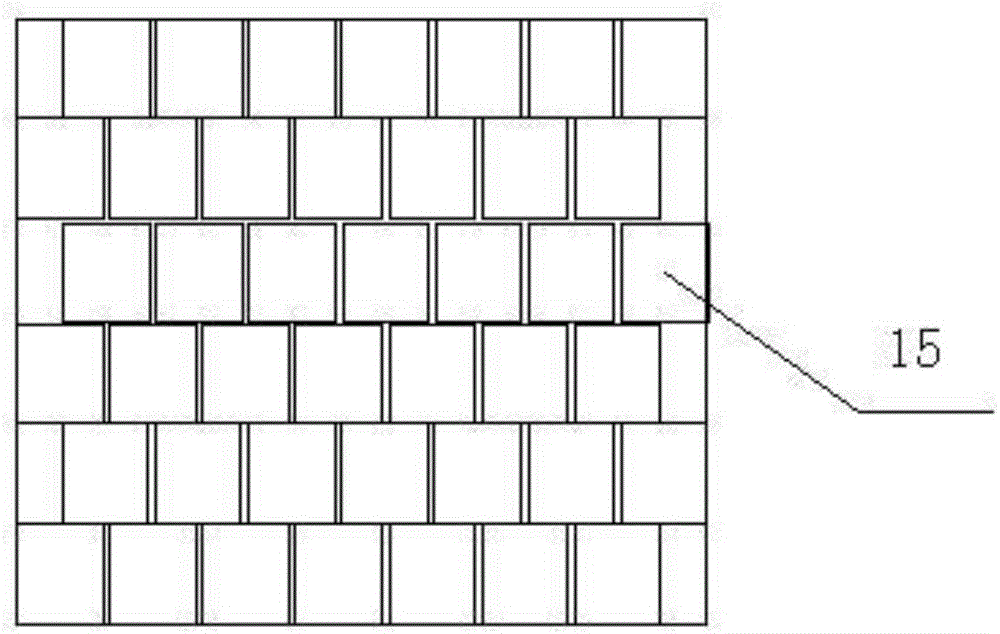

[0042] see image 3 , and the difference from Example 1 is: the packing is composed of several Pall rings, and adjacent Pall rings are stacked and arranged alternately. Several passages formed by the Pall ring can also make the size of the mineralized bubbles passing through the filler uniform, reduce back-mixing and entrainment of non-floatable minerals, and improve the quality of the concentrate. Of course, other fillers can also be used in this application, as long as channels can be formed and mineralized bubbles passing through the filler can be made uniform in size.

[0043] The present invention also provides a method for mineral separation with the above-mentioned flotation column enhanced separation device having a packing structure, comprising the following steps:

[0044] 1) The raw ore pulp that has been prepared by the agent enters the column 5 through the raw ore feeding pipe 8 at a certain pressure, and the raw ore pulp descends under the action of gravity, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com