Chemical modified titanium dioxide photocatalyst and preparation method thereof

A technology of titanium dioxide and photocatalyst, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., to achieve the effect of improving activation performance, simple preparation method, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

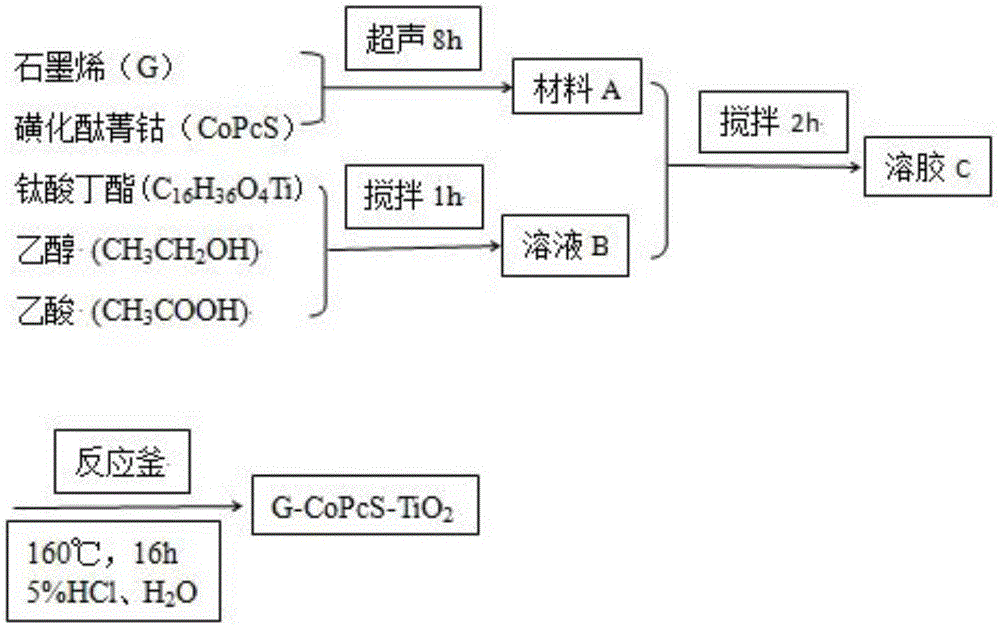

[0028] A preparation method of a chemically modified titanium dioxide photocatalyst, comprising the steps of:

[0029] Step 1: Add 6 mg of graphene and 300 mg of sulfonated cobalt phthalocyanine to 36 mL of deionized water, centrifuge after ultrasonic reaction for 8 hours and remove the supernatant, and dry to obtain 14.2 mg of graphene-sulfonated cobalt phthalocyanine composite;

[0030] Step 2, slowly drop 17mL of butyl titanate into the mixture of 34ml of ethanol and 4.8mL of acetic acid while stirring, finish dropping in 60 minutes, and mix evenly to obtain solution B;

[0031] Step 3: Add 14.2 mg of graphene-sulfonated cobalt phthalocyanine composite into the mixed solution B while stirring, and stir magnetically for 2 hours to obtain a sol;

[0032] Step 4, put the sol in a 100mL reaction kettle, react at 160°C for 16h, rinse the product with 50mL of hydrochloric acid and deionized water with a concentration of 5% by mass, and then dry it in an oven at 80°C for 8 hours,...

Embodiment 2

[0034] A preparation method of a chemically modified titanium dioxide photocatalyst, comprising the steps of:

[0035] Step 1: Add 6 mg of graphene and 300 mg of sulfonated cobalt phthalocyanine into 36 mL of deionized water, centrifuge after ultrasonic reaction for 10 hours, remove the supernatant, and obtain 14.2 mg of graphene-sulfonated cobalt phthalocyanine composite after drying;

[0036] Step 2, slowly drop 17mL of butyl titanate into the mixture of 34ml of ethanol and 4.8mL of acetic acid while stirring, finish dropping in 60 minutes, and mix evenly to obtain solution B;

[0037] Step 3: Add 14.2 mg of graphene-sulfonated cobalt phthalocyanine composite into the mixed solution B while stirring, and stir magnetically for 2 hours to obtain a sol;

[0038] Step 4, put the sol in a 100mL reactor, react at 200°C for 20h, wash the product with 50mL of hydrochloric acid and deionized water with a concentration of 5% by mass, and then dry it in an oven at 80°C for 8 hours, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com