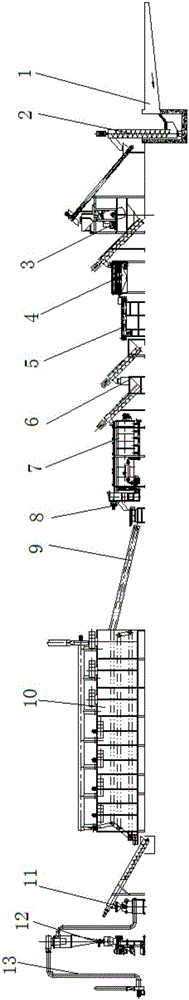

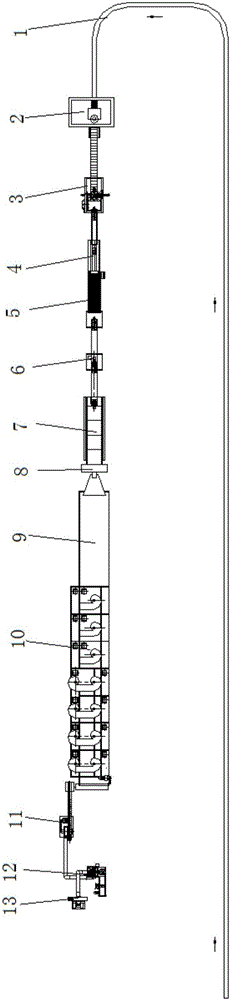

Complete production equipment for whole potato flour

A technology of raw potato powder and complete sets of equipment, applied in the direction of food science, etc., to achieve the effect of reducing loss rate, reducing production cost, and low equipment investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Selection of raw materials: Choose pure varieties, mature and fresh potatoes, and strictly remove the germinated, green and mildewed parts. Its length is 50-200 mm, and its diameter is 50-100 mm.

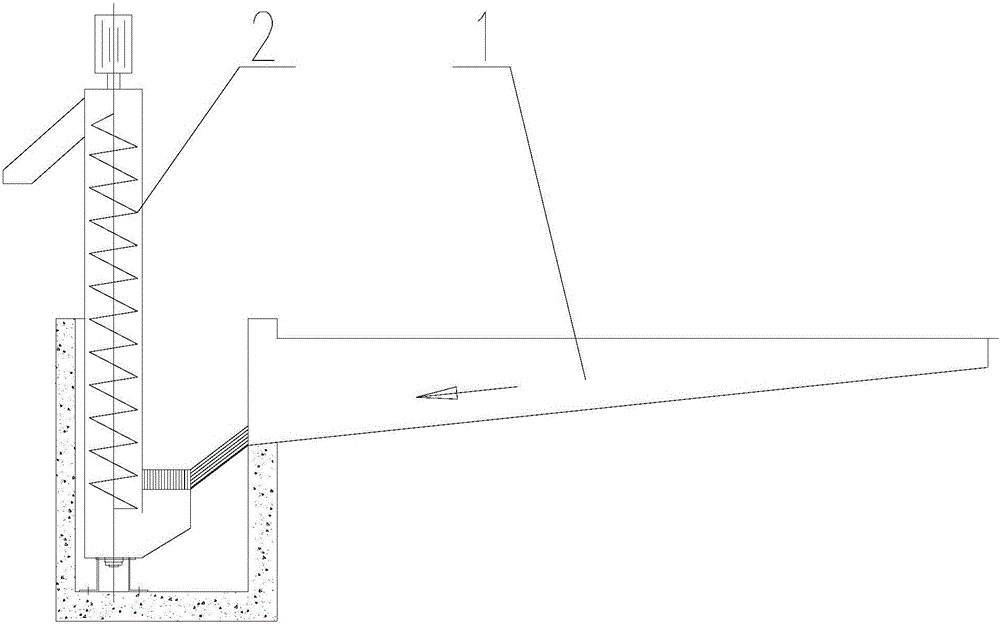

[0046] (2) Water cleaning and transportation: Under the action of water flow, the raw materials are transported from the warehouse to the spiral destoner elevator in the production workshop, and at the same time, the mud and sand on the surface of the raw materials are preliminarily cleaned.

[0047] (3) Spiral lifting and stone removal: Utilizing the difference in specific gravity between the stone and the raw material, the stone sinks to the bottom and separates from the raw material, and the raw material suspended in the water is sucked by the spiral blade, lifted to a certain height, and sent to the entrance of the scraper elevator.

[0048] (4) Scraper lifting: Raw materials are lifted by the scraper and sent to the steam blasting machine.

[0049] (5) Steam skin ex...

Embodiment 2

[0062] (1) Selection of raw materials: Choose pure varieties, mature and fresh potatoes, and strictly remove the germinated, green and mildewed parts. Its length is 50-200 mm, and its diameter is 50-100 mm.

[0063] (2) Water cleaning and transportation: Under the action of water flow, the raw materials are transported from the warehouse to the spiral destoner elevator in the production workshop, and at the same time, the mud and sand on the surface of the raw materials are preliminarily cleaned.

[0064] (3) Spiral lifting and stone removal: Utilizing the difference in specific gravity between the stone and the raw material, the stone sinks to the bottom and separates from the raw material, and the raw material suspended in the water is sucked by the spiral blade, lifted to a certain height, and sent to the entrance of the scraper elevator.

[0065] (4) Scraper lifting: Raw materials are lifted by the scraper and sent to the steam blasting machine.

[0066] (5) Steam skin ex...

Embodiment 3

[0079] (1) Selection of raw materials: Choose pure varieties, mature and fresh potatoes, and strictly remove the germinated, green and mildewed parts. Its length is 50-200 mm, and its diameter is 50-100 mm.

[0080] (2) Water cleaning and transportation: Under the action of water flow, the raw materials are transported from the warehouse to the spiral destoner elevator in the production workshop, and at the same time, the mud and sand on the surface of the raw materials are preliminarily cleaned.

[0081] (3) Spiral lifting and stone removal: Utilizing the difference in specific gravity between the stone and the raw material, the stone sinks to the bottom and separates from the raw material, and the raw material suspended in the water is sucked by the spiral blade, lifted to a certain height, and sent to the entrance of the scraper elevator.

[0082] (4) Scraper lifting: Raw materials are lifted by the scraper and sent to the steam blasting machine.

[0083] (5) Steam skin ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com