Whole wheat boiled noodle

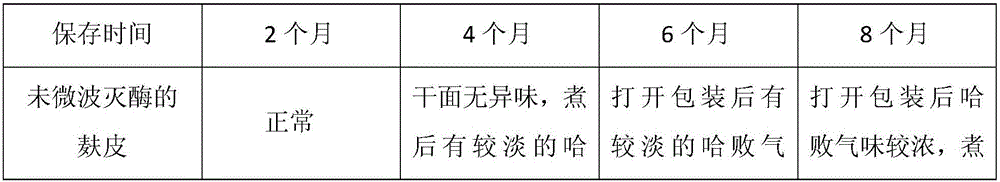

A flour, cornmeal technique applied to whole wheat lo mein. In the field, it can solve the problems of flour acidification, hardening, fatty acid value increase, etc., and achieve the effect of improving quality, reducing water absorption rate, and reducing water addition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

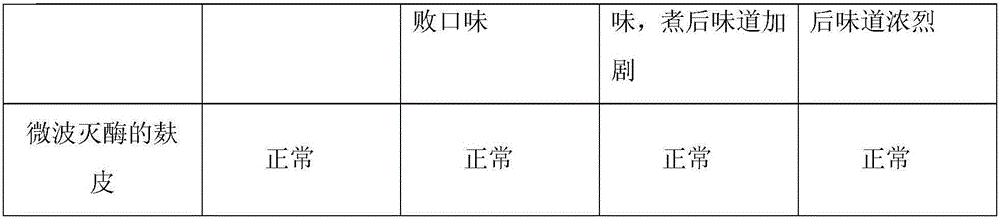

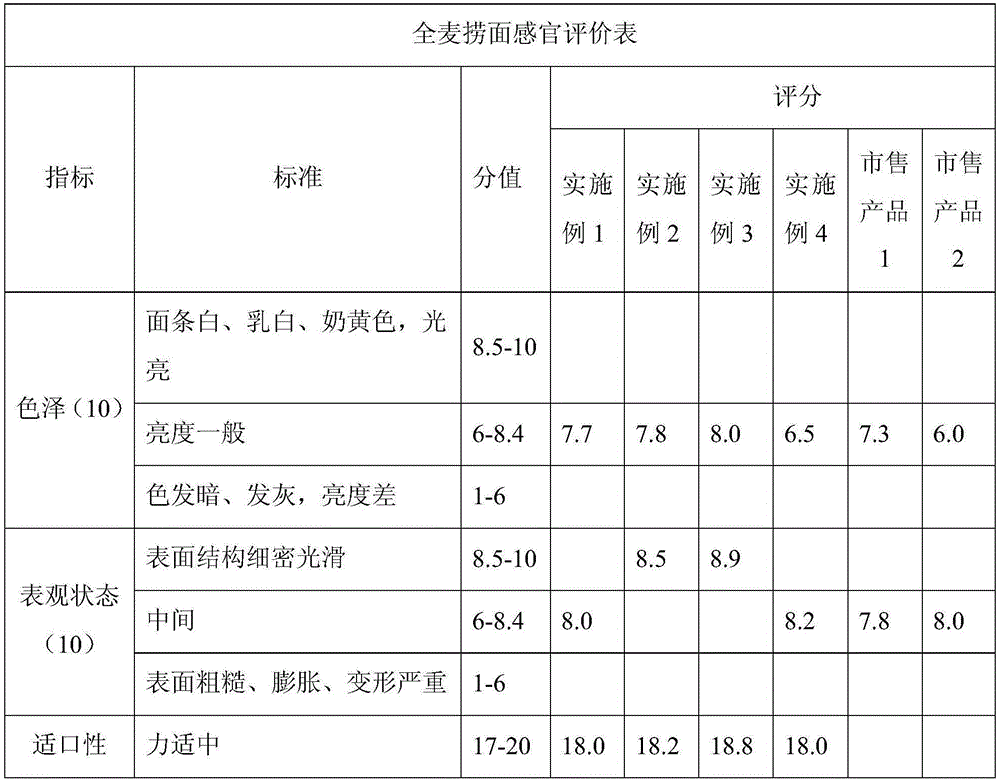

Embodiment 1

[0049] A preparation method for whole wheat lo mein, comprising the steps of:

[0050] Mix 10 parts of cornmeal and 10 parts of bran and steam for 3 minutes at a steam temperature of 100°C and a steam pressure of 1.05kg / cm 2 ; The steamed cornmeal and bran are subjected to microwave enzymatic treatment for 3min, the heating power of the microwave is 3kw, and the frequency is 915MHz; , 2 parts of wheat gluten, 0.08 part of calcium sodium stearoyl lactylate, 2 parts of edible salt and 30 parts of water are mixed evenly to make a dough mixing agent; cornmeal and bran, dough mixing agent and 70 parts of flour will be processed through deactivating enzymes Put it into the noodle mixer and knead the dough for 30 minutes to make the dough; put the prepared noodle at rest for 20 minutes; after the rest, the dough is rolled into a strip that meets the requirements and then cut into strips Drying the sliced noodles at a low temperature of 30°C for 4 hours, and the water content of th...

Embodiment 2

[0052] Mix 8 parts of cornmeal and 5 parts of bran for steaming treatment for 3 minutes, the steam temperature is 110°C, and the steam pressure is 1.1kg / cm 2 ; The cornmeal and bran of steaming treatment are carried out microwave to kill enzyme treatment 5min, and the heating power of microwave is 2kw, and frequency is 915MHz; ), 2 parts of wheat gluten, 0.06 part of calcium sodium stearoyl lactylate, 3 parts of edible salt and 25 parts of water are mixed evenly to make a dough mixing agent; A portion of flour is put into a dough mixer and kneaded for 20 minutes to make a dough; the dough is left to stand for 25 minutes; Cutting into strips; drying the sliced noodles at a low temperature of 30°C for 4 hours, and the water content of the finished noodles is 12%; cutting, measuring and packaging the dried noodles to obtain the finished whole wheat lo mein.

Embodiment 3

[0054] Mix 10 parts of cornmeal and 8 parts of bran and steam for 5 minutes at a steam temperature of 110°C and a steam pressure of 1.05kg / cm 2 ; The cornmeal and bran processed through steaming are carried out microwave enzymatic treatment 4min, and the heating power of microwave is 5kw, and frequency is 915MHz; ), 3 parts of wheat gluten, 0.08 part of calcium sodium stearoyl lactylate, 2 parts of edible salt and 30 parts of water are mixed evenly to make a dough-mixing agent; Put one portion into the dough mixer and knead the dough for 30 minutes to make the dough; put the prepared dough in a standing state for 20 minutes; the dough after standing is multi-stage rolled into a dough strip that meets the requirements and then cut strips; dry the sliced noodles at 30°C for 4.5 hours at low temperature, and the water content of the finished noodles is 15%; cut, measure and pack the dried noodles to obtain the finished whole-grain lo mein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com