Potato planting machine

A potato planter and frame technology, applied to potato planters, planting methods, plant protection covers, etc., can solve the problems of increased labor time, low degree of automation, and large labor load, and achieve reduced labor time and high degree of automation , the effect of reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

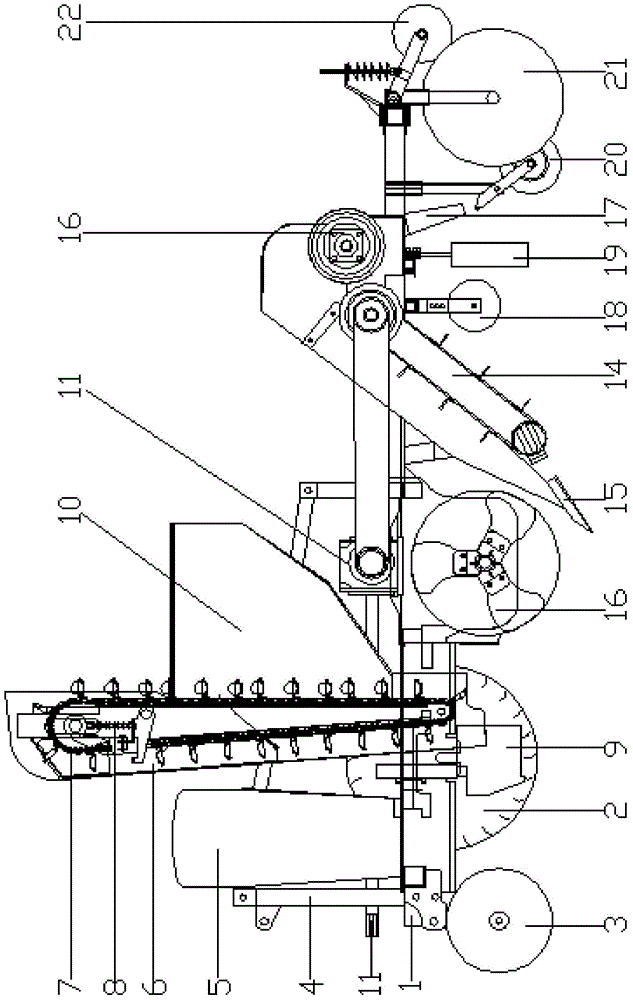

[0010] According to attached figure 1 Described, potato planting machine, comprises frame 1, fertilization ditching disc 3, seed shoe ditching device 9, fertilizer box 5, promotes seed protection groove 6, seed box 10, ridging device 13, ditching shovel 15, lifting Soil lifting device 14, spreading film roller 19, auger soil sending device 16, pressing film wheel 20 and pressing wheel 22, the position of the beam on both sides of the frame 1 is correspondingly provided with a ground wheel device 2 near the front beam, and the frame 1. The lower part of the center position of the front beam is provided with a fertilization ditching disc 3, and a vertical traction device 4 is installed on the frame 1 front beam top which is equal to the distance from the left and right sides of the fertilization ditching disc 3, and the frame 1 top near the traction device 4 is installed There are two groups of symmetrical fertilizer boxes 5, and the rear sides of the fertilizer boxes 5 are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com