Vacuum pump system and method for operating a vacuum pump system

A vacuum pump and catheter technology, applied in the direction of pumps, pump components, rotary piston pumps, etc., can solve problems such as high energy consumption, achieve energy saving, achieve the effect of pumping capacity, and high pumping capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

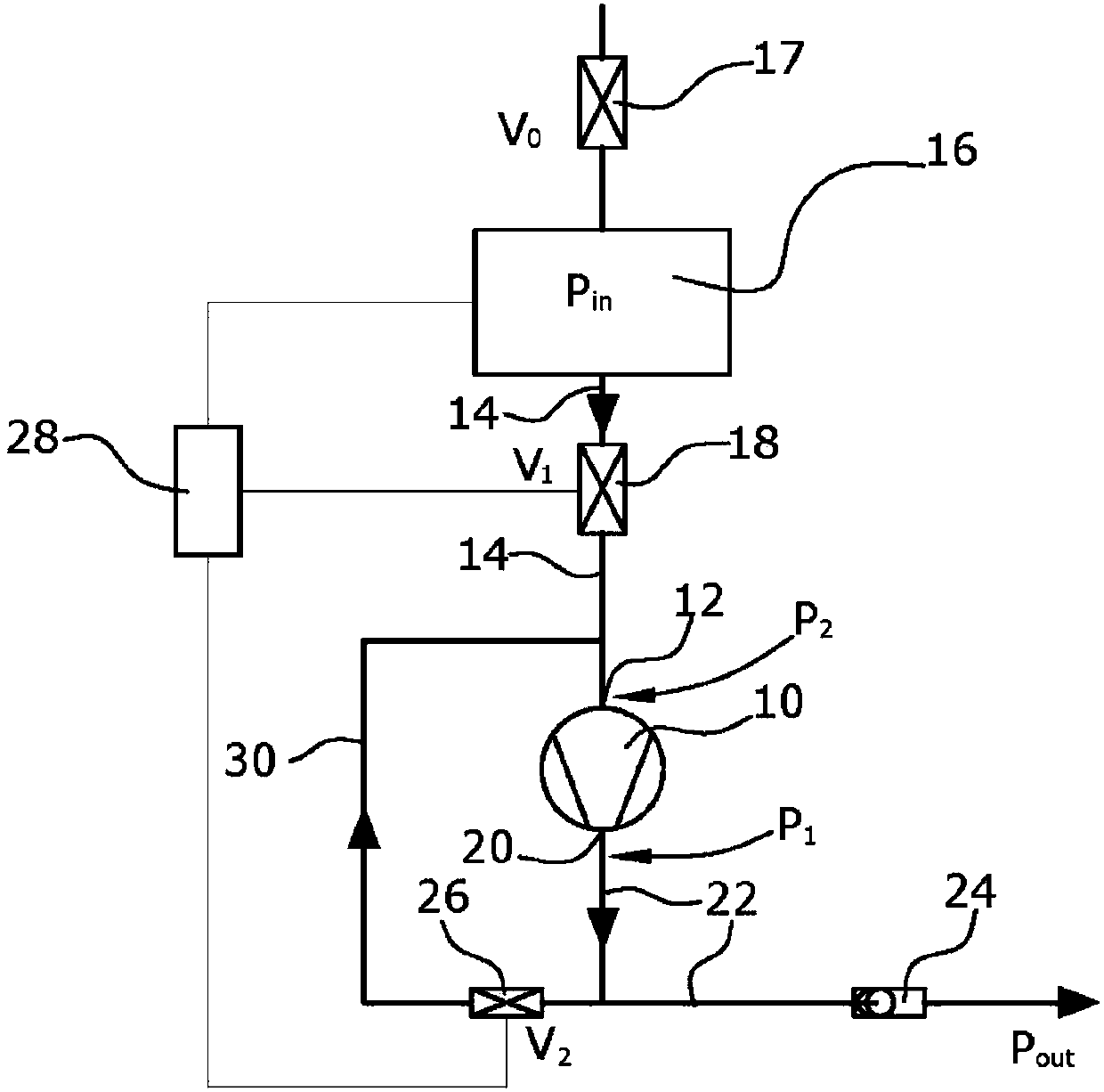

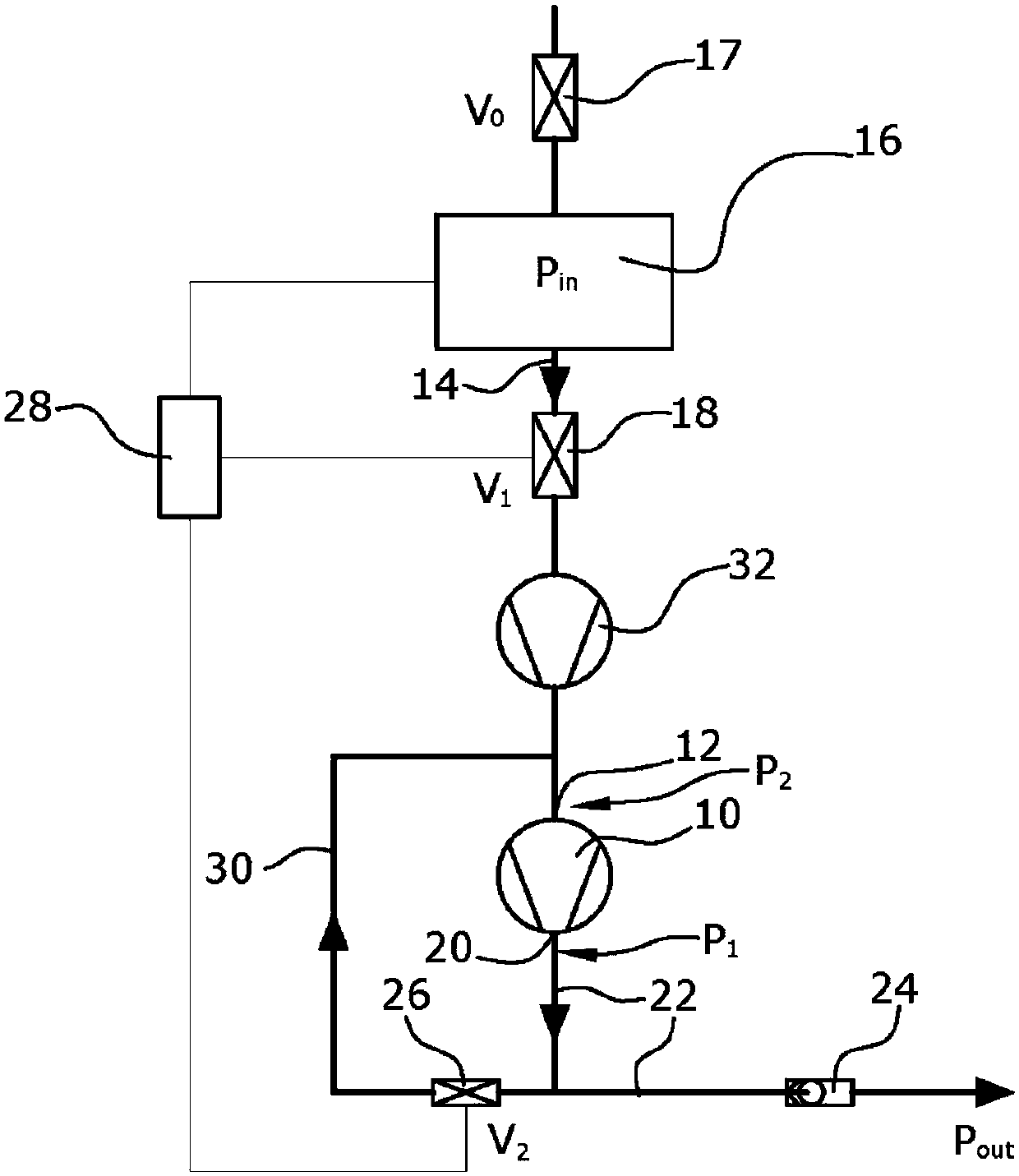

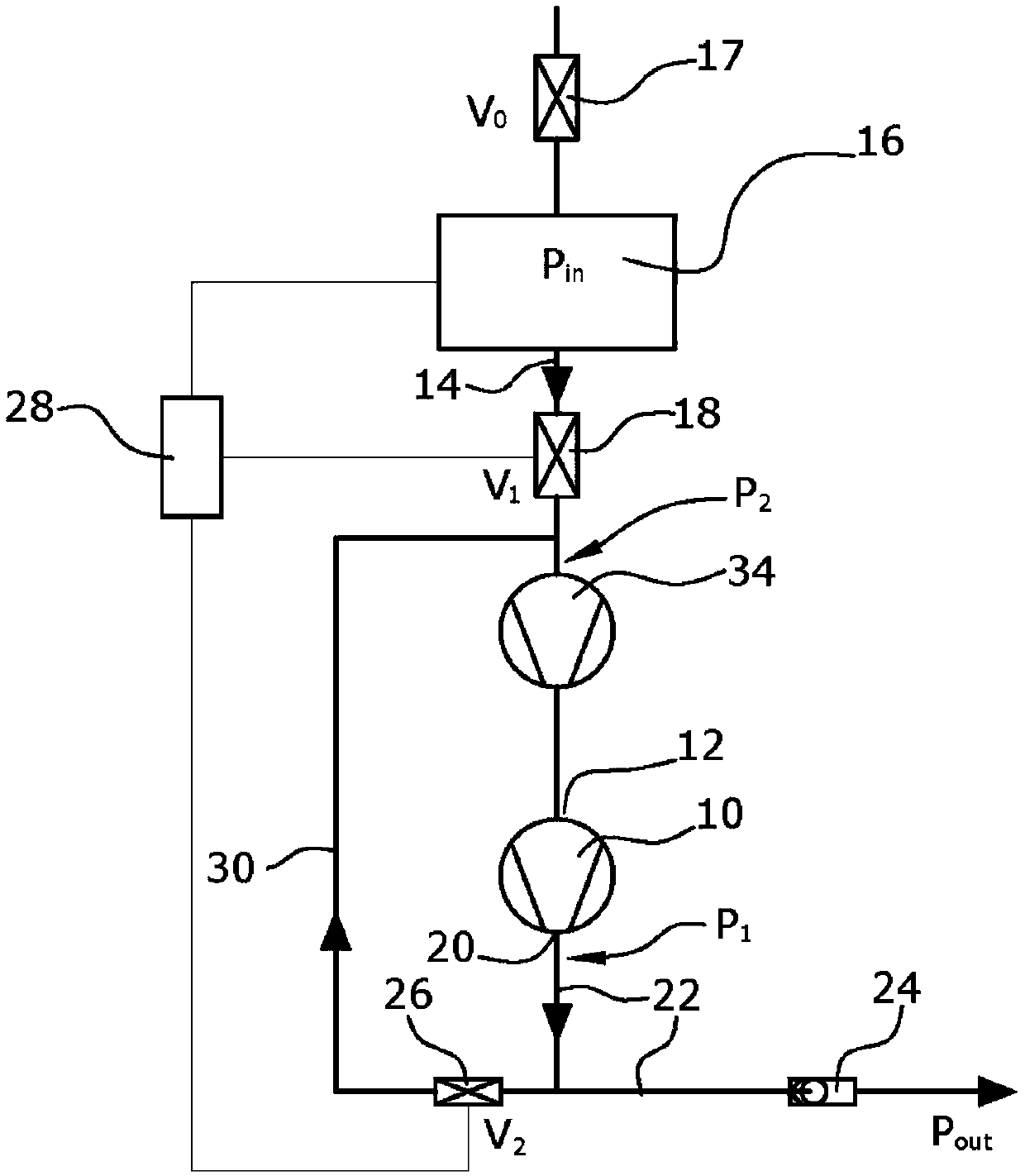

[0037] figure 1 The vacuum pump shown in includes a screw pump 10. The inlet 12 of the vacuum pump is connected via an inlet conduit 14 to a chamber, such as a lock chamber or process chamber 16 . Chamber 16 has a valve 17 (valve V 0 ) to close the import. Inlet valve 18 (valve V 1 ), specifically the controllable inlet valve is arranged in the inlet conduit 14 .

[0038] The outlet 20 of the vacuum pump 10 is connected to an outlet conduit 22 in which a check valve 24 is arranged. Outlet line 22 may be immediately connected to the atmosphere or to an exhaust system having a predetermined system pressure. The system pressure can be above or below atmospheric pressure.

[0039] Further, the outlet conduit 22 is connected to the inlet conduit 14 via a bypass conduit 30 . Bypass valve 26 (valve V 2 ) is in particular an electrically switchable bypass valve arranged in the bypass conduit 30 . Further, a control device 28 is provided, which is connected to at least the inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com