Lithium battery pack utilizing phase-change material to realize temperature control

A phase change material and temperature control technology, which is applied to battery pack components, secondary batteries, circuits, etc., can solve the problem of uneven heat conduction, improve performance, facilitate miniaturization and improve design, and occupy less space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

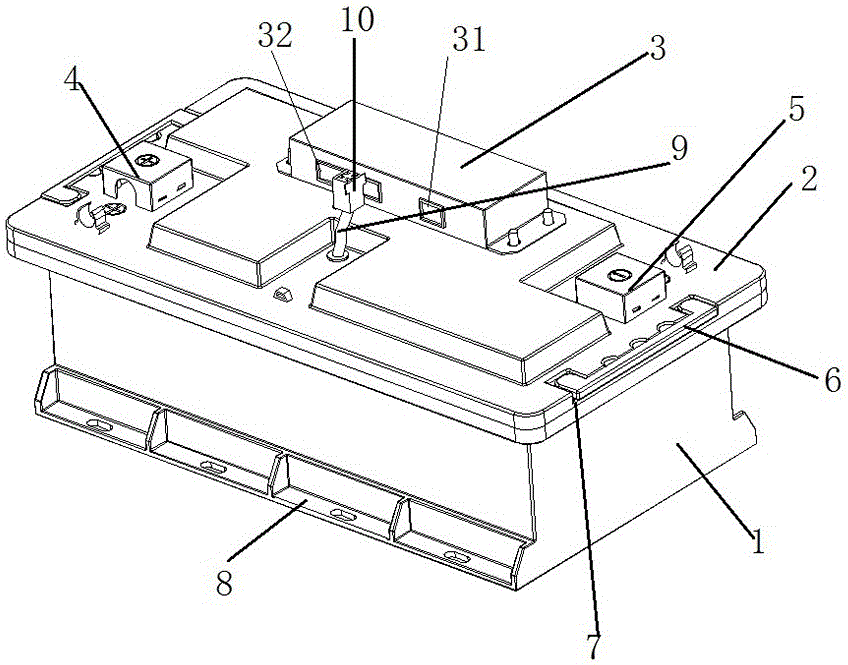

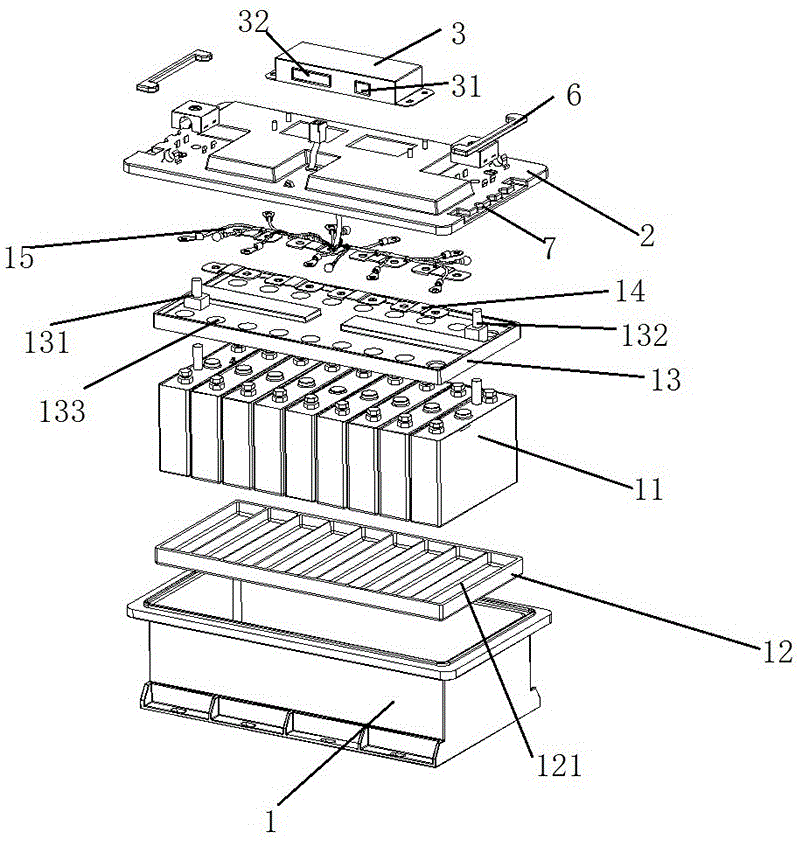

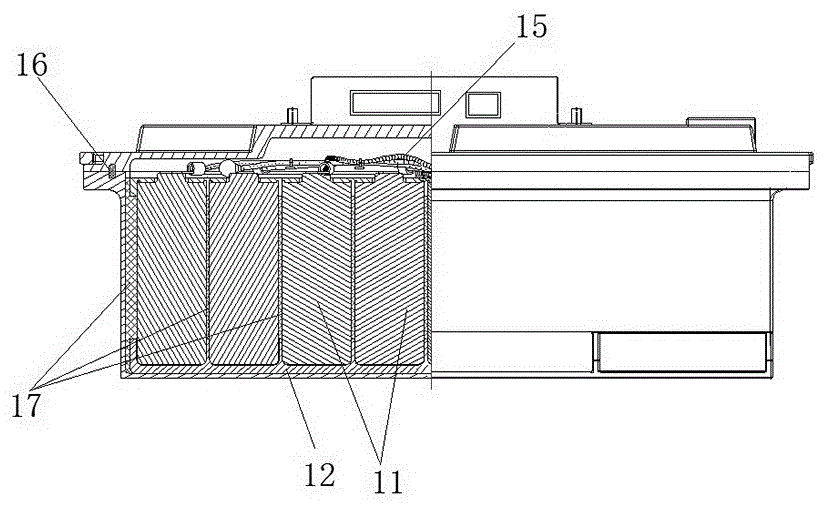

[0028] The specific embodiment of the lithium battery pack utilizing phase change material to realize temperature control provided by the present invention, such as Figure 1 to Figure 6 As shown, the lithium battery pack includes a lower case 1 and an upper case 2 that are hermetically assembled to form an inner cavity, and a partition plate 13 is arranged in the inner cavity to divide the inner cavity into an upper cavity and a lower cavity, The lower cavity is a sealed cavity, and a plurality of lithium batteries 11 are fixedly arranged in the sealed cavity through the battery holding structure, and each lithium battery 11 is respectively coated with a heat conductor to form a lithium battery unit. The heat conductor in this embodiment Specifically, it is a heat-conducting film, which is in the form of thermosetting colloid. The surface of the battery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com