Multi-shaft motion controller and control method of closed-loop PWM pulse

A multi-axis motion and control method technology, applied in the direction of program control, computer control, general control system, etc., can solve the problems that it is difficult to ensure timely response to interrupt events, cannot achieve high-precision pulse output, and poor high-speed control capabilities. Achieve the effects of easy expansion of applications, simplified board peripheral circuits, and low hardware costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

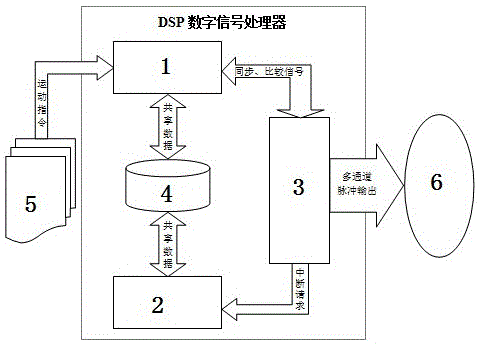

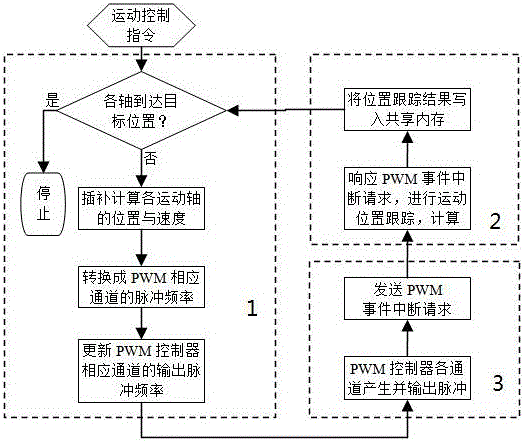

[0021] Preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings, referring to the appended Figures 1 to 2 As shown, the present invention is realized by the following technical solutions, including main processor core 1, upper computer 5, servo drive 6, connected by serial bus between upper computer 5 and main processor core 1, and motion instruction data is transmitted to the main computer. The processor core 1 also includes a coprocessor core 2 and an integrated multi-channel PWM controller 3, and a shared memory 4, the PWM controller 3 and the coprocessor core 2 jointly complete position tracking; the shared memory 4 1, the main processor core 1, the PWM controller 3, and the coprocessor core 2 are sequentially connected to form a closed loop.

[0022] The main processor core 1 and the coprocessor core 2 work in parallel, have their own independent running memory spaces, and exchange data through the share...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com