steam generator

A steam generation device and vaporization chamber technology, applied in steam generation, steam generation method, valve device, etc., can solve the problems of uncontrollable water volume and delivery frequency of the digester, uncertain working frequency and force of water pump, and inability to realize uniform motion, etc. , to achieve the effect of unmanned automatic operation, stable structure, and avoid dry burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

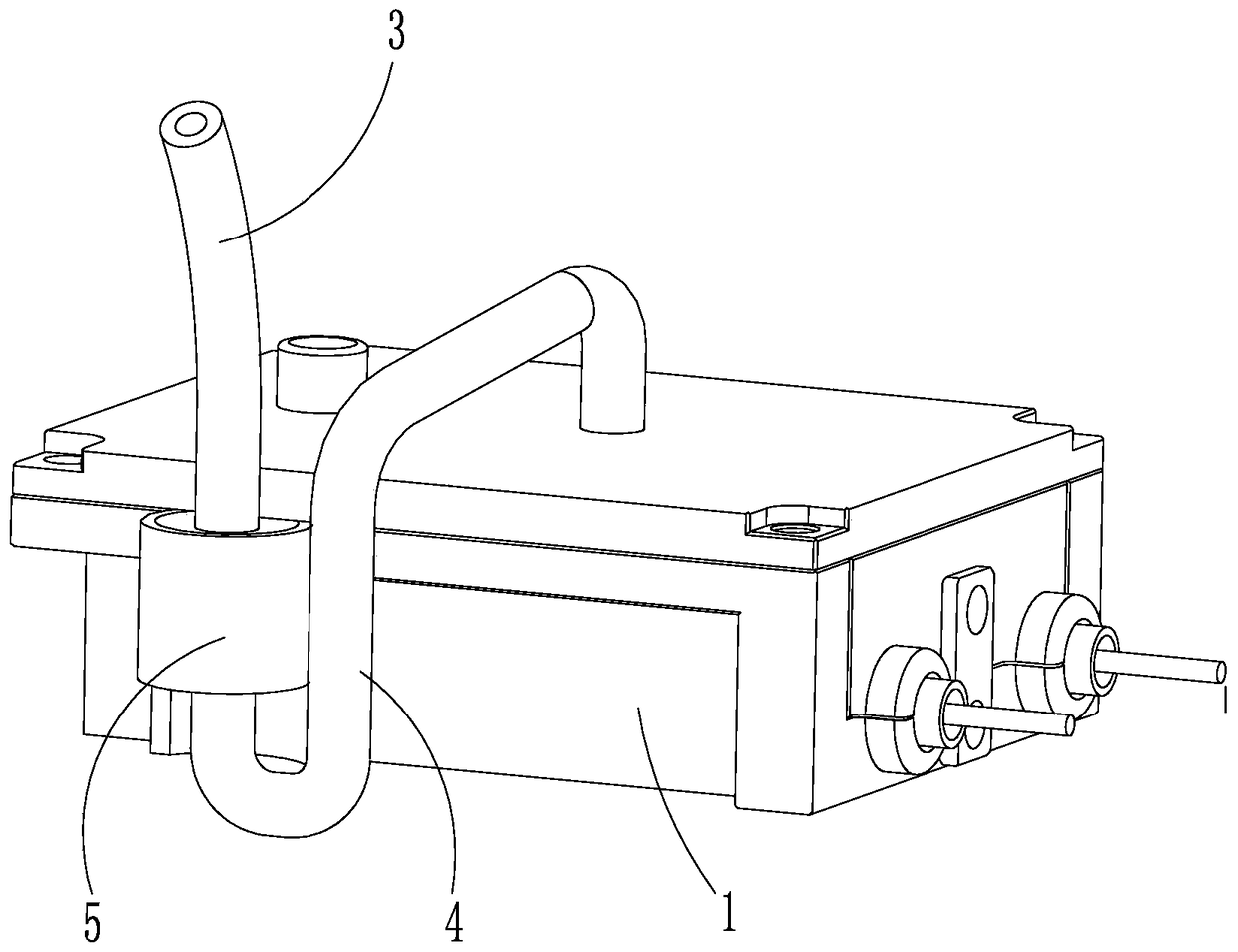

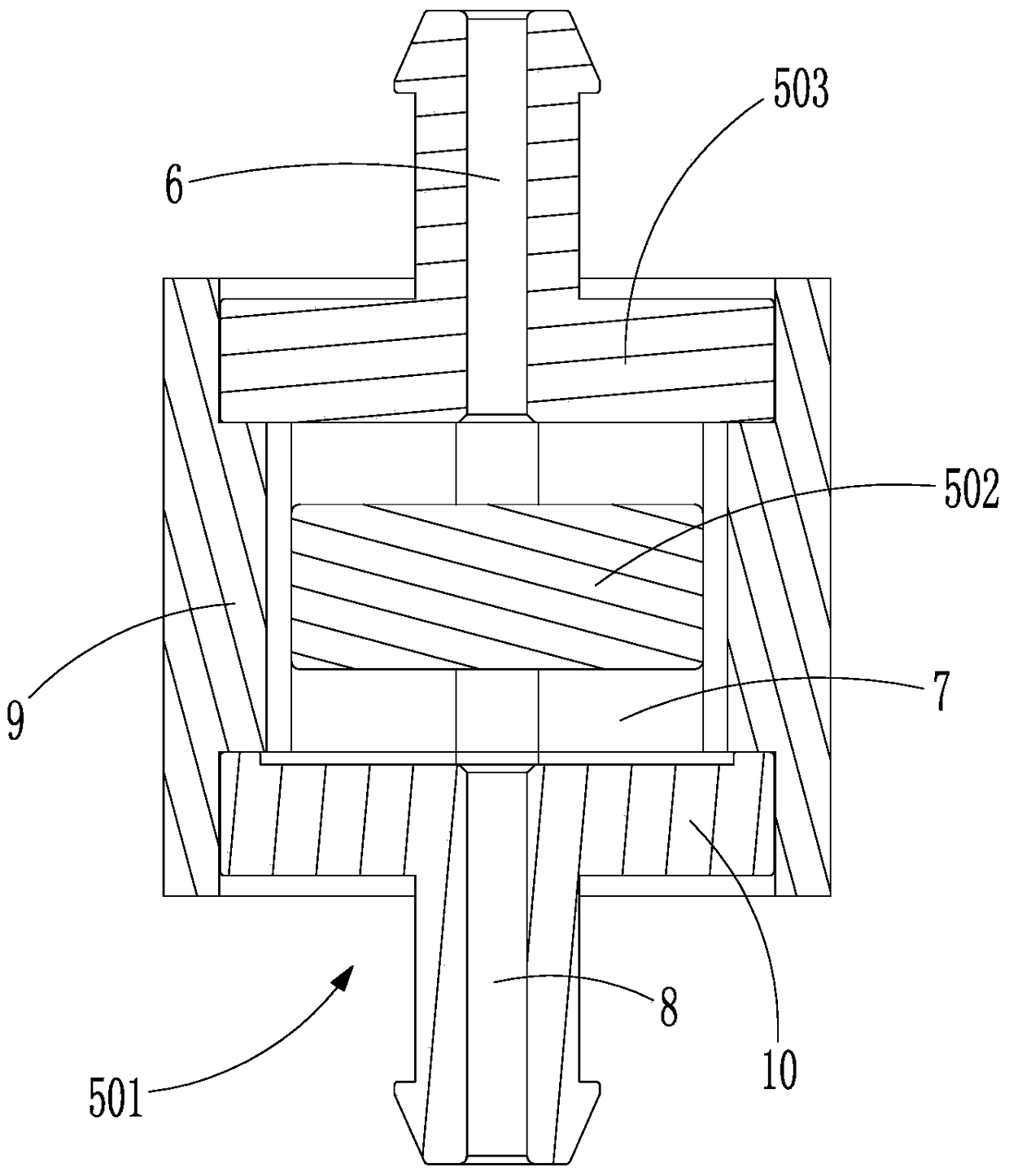

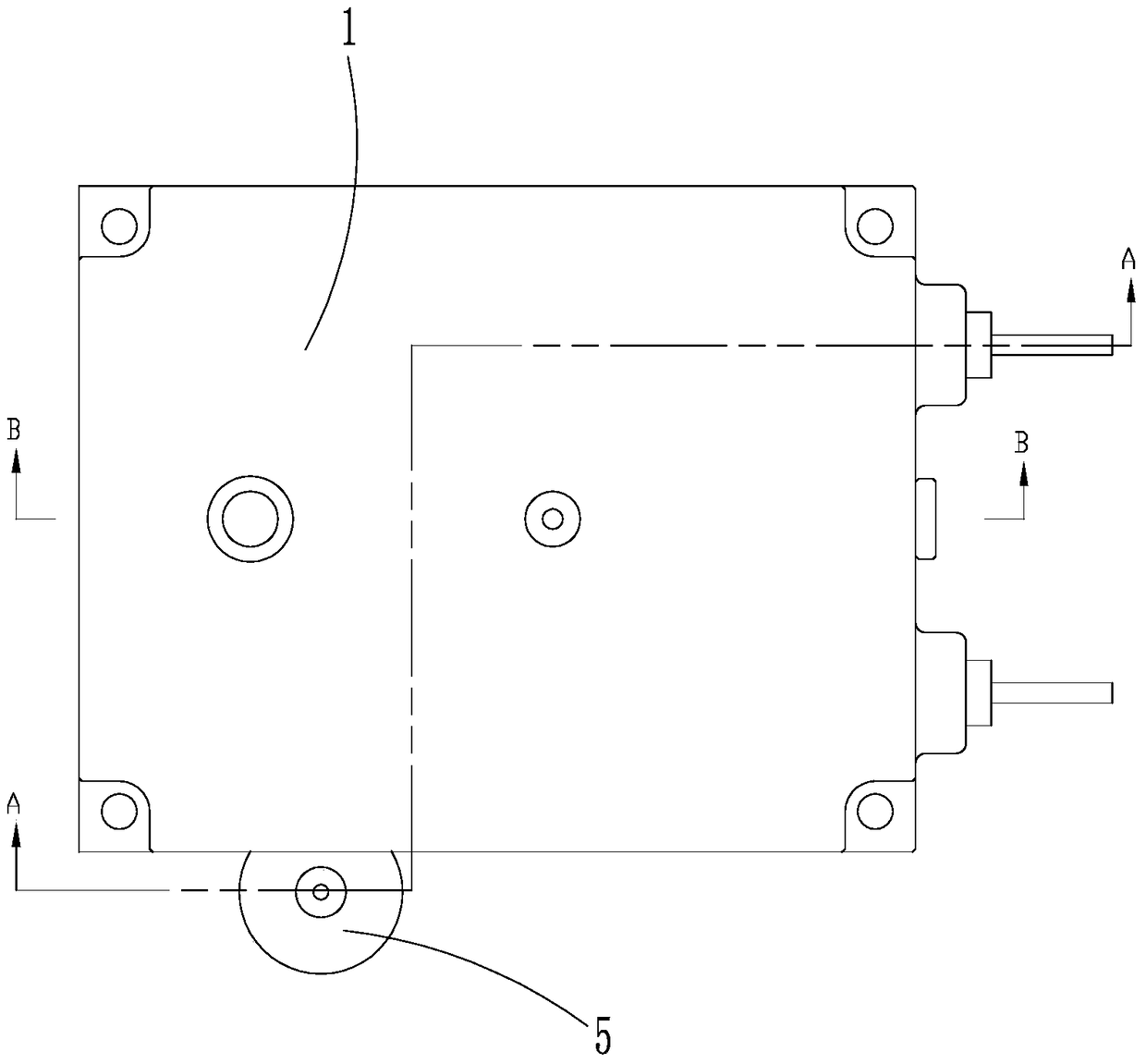

[0018] Example 1: as attached figure 1 , 3 , 4 and 5, a steam generating device includes a heater, the heater includes a heating body 1 with an electric heating wire embedded therein, a vaporization chamber 2 is arranged inside the heating body 1, and a vaporization chamber 2 is arranged on the heating body 1. 2. The water inlet channel and the steam discharge channel are connected. The water inlet channel is used to connect with a water supply source. The water inlet channel is provided with a magnetic valve 5. The water inlet end of the magnetic valve 5 is connected with a water inlet pipe 3 and a water outlet end. There is a water outlet pipe 4, that is, the water outlet pipe 4 is connected between the magnetic valve 5 and the heater, as shown in the appendix figure 2 As shown, the solenoid valve 5 includes a valve seat 501 and a valve core 502, the valve seat 501 includes an upper cover, a middle hollow cylinder 9 and a lower lower cover 10, the valve core 502 is made of...

Embodiment 2

[0023]Embodiment 2: A steam generating device, including a heater, the heater includes a heating body with an electric heating wire embedded therein, a vaporization chamber is arranged inside the heating body, and a water inlet channel and a water inlet channel which are all communicated with the vaporization chamber are arranged on the heating body. The steam discharge channel, the water inlet channel is used to connect with a water supply source, a magnetic valve is arranged on the water inlet channel, the magnetic valve includes a valve seat and a valve core, and a part in the valve seat and the valve core is at least partially made of permanent magnet material At least part of the other part is made of a material that can be attracted to the permanent magnet, and at least part of the part made of the permanent magnet material is in gas communication with the vaporization chamber, that is, the operation of the solenoid valve is controlled by the steam generated by heating St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com