Inclined trough type 2D electro-hydraulic high-speed switching valve with variable transmission ratio transmission mechanism

A technology of high-speed switching valve and transmission mechanism, which is applied to engine components, valve details, multi-port valves, etc., can solve problems such as damage to the overall structure of the valve body, difficulty in processing the valve core, and reduce the rigidity of the valve core, so as to achieve low processing costs. , Improve reliability and stability, increase the effect of area gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

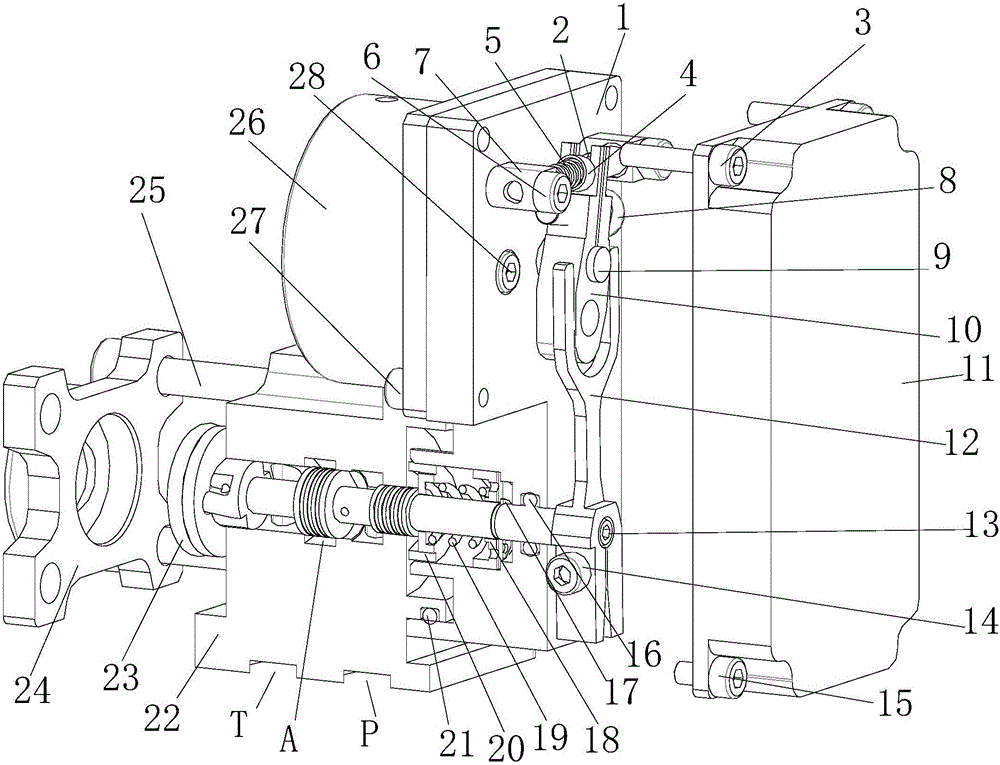

[0042] As shown in the figure, a chute type 2D electro-hydraulic high-speed switching valve with a variable transmission ratio transmission mechanism includes a valve body, a transmission mechanism that drives the valve body to open, and a zero position holding mechanism that drives the valve body to close;

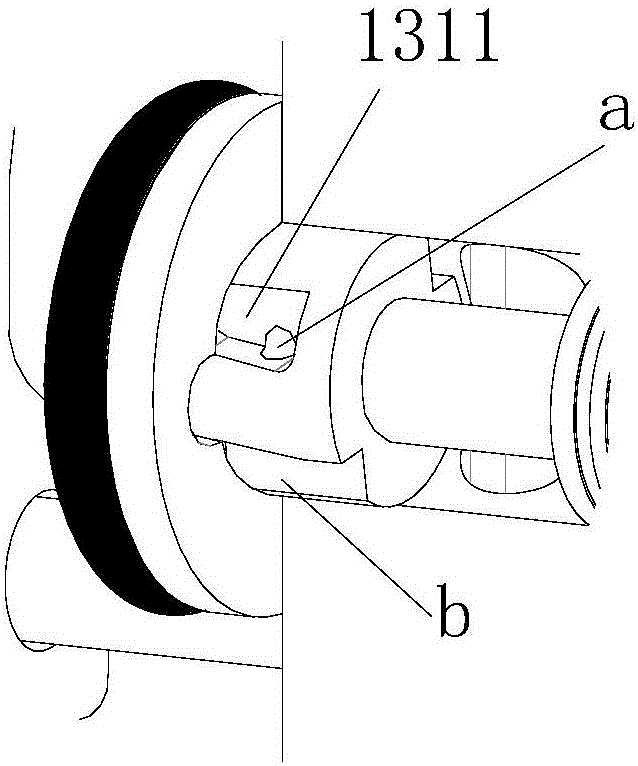

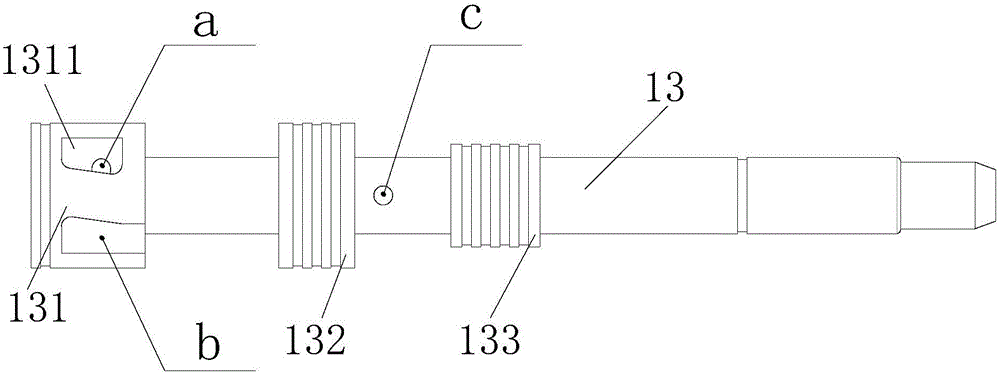

[0043] The valve body includes a servo screw mechanism composed of a valve body 22 and a valve core 13. The valve core 13 is rotatably arranged in the valve body 22. The valve core 13 is sequentially provided with a first shoulder 131 and a second shoulder from left to right. 132 and the third shoulder 133, the left end cap 24 of the valve body 22 and the first shoulder 131 airtightly separate the inner cavity of the valve body 22 into a sensitive cavity f, the first shoulder 131 and the second shoulder 132 separate the valve body The inner cavity of 22 is airtightly partitioned into an annular oil outlet cavity m surrounding the valve core 13, and the second shoulder 132 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com