Tunnel siphon water drainage system and construction method thereof

A technology of drainage system and construction method, which is applied in the directions of drainage, earthwork drilling, safety devices, etc., can solve the problems of water seepage, increased water pressure, increase, etc., and achieves a small damage slope, simple construction method, and convenient maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

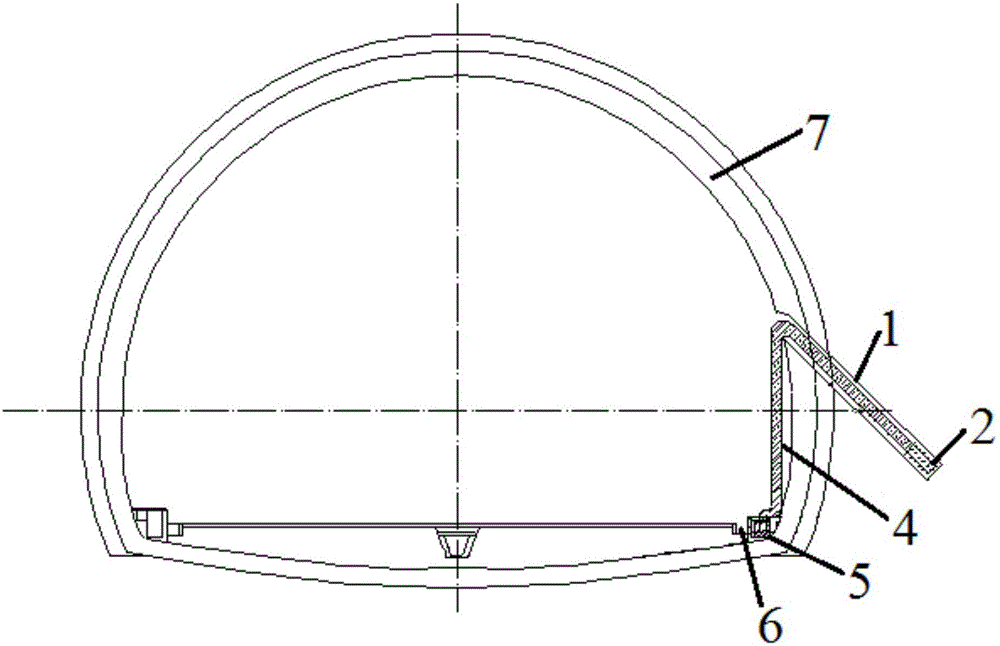

[0033] A tunnel siphon drainage system, the drainage system includes a borehole 1 set at the seepage point of the tunnel wall 7 and inclined downwards, a water reservoir 2 arranged at the bottom of the borehole 1, and a siphon sleeve connected to the water reservoir 2 in sequence Pipe 4, water storage barrel 5 and longitudinal drainage ditch 6, the angle between the borehole 1 and the vertical direction is 45°, one end of the siphon sleeve 4 is inserted into the borehole 1 and communicated with the water storage 2, and the other end is connected to the borehole 1 One place is drawn vertically and placed in the water storage barrel 5, and the water outlet of the siphon sleeve 4 is 40cm lower than the position of the water reservoir 2.

[0034] The borehole 1 is opened at the side wall of the tunnel cross section at the water seepage point of the tunnel wall 7, and the borehole 1 is 1.0m higher than the bottom of the tunnel. The borehole 1 has a diameter of 35mm and a length of ...

Embodiment 2

[0049] A tunnel siphon drainage system, the drainage system includes a borehole 1 set at the seepage point of the tunnel wall 7 and inclined downwards, a water reservoir 2 arranged at the bottom of the borehole 1, and a siphon sleeve connected to the water reservoir 2 in sequence Tube 4, water storage barrel 5 and longitudinal drainage ditch 6, the angle between borehole 1 and the vertical direction is 75°, one end of siphon sleeve 4 is inserted into borehole 1 and communicated with water storage 2, and the other end is connected to the borehole One place is drawn vertically and placed in the water storage bucket 5, and the water outlet of the siphon sleeve 4 is 60cm lower than the position of the water storage tank 2.

[0050] The borehole 1 is opened at the side wall of the tunnel cross section at the seepage point of the tunnel wall 7, and the borehole 1 is 1.5m higher than the bottom of the tunnel. Borehole 1 has a diameter of 45 mm and a length of 2.0 m.

[0051] The sip...

Embodiment 3

[0062] A tunnel siphon drainage system, the drainage system includes a borehole 1 set at the seepage point of the tunnel wall 7 and inclined downwards, a water reservoir 2 arranged at the bottom of the borehole 1, and a siphon sleeve connected to the water reservoir 2 in sequence Tube 4, water storage barrel 5 and longitudinal drainage ditch 6, the angle between borehole 1 and the vertical direction is 60°, one end of siphon sleeve 4 is inserted into borehole 1 and communicated with water storage 2, and the other end is connected with the borehole One place is drawn vertically and placed in the water storage bucket 5, and the water outlet of the siphon sleeve 4 is 50cm lower than the position of the water storage tank 2.

[0063] The borehole 1 is opened at the side wall of the tunnel cross section at the seepage point of the tunnel wall 7, and the borehole 1 is 1.2m higher than the bottom of the tunnel. The borehole 1 has a diameter of 42mm and a length of 1.8m.

[0064] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com