Spinning, vacuumizing and mixing extruder of dacron waste cloth

A technology of mixing and extruding polyester waste, which is applied in the field of polyester waste spinning vacuum mixing extruder, can solve the problems of reducing the tensile strength of polyester yarn, failing to meet the use requirements, and low recycling rate. To achieve the effect of improving the mixing effect, ensuring the tensile strength and improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0057] When in use, the first step is to clean up the recycled variegated polyester waste cloth to remove debris and dust for later use;

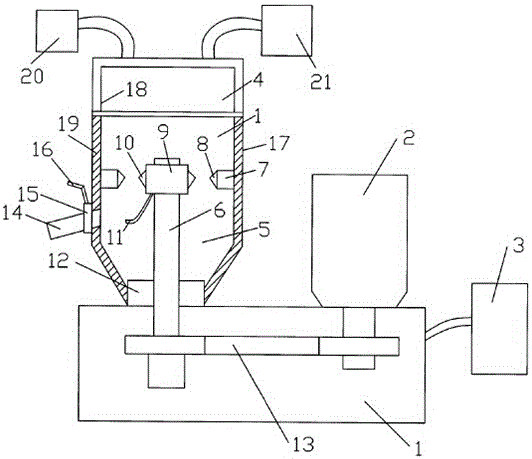

[0058] In the second step, put the cleaned variegated polyester waste cloth into the agglomerator 21, start the granulator 21 to work, and crush the variegated polyester waste cloth into tiny flakes. With the high-speed rotation of the granulator 21 blades, the When the temperature of the polyester material rises to 180°C or 200°C or 220°C (preferably 200°C), the softened polyester material is shrunk by spraying liquid nitrogen through the cooling liquid nitrogen supply device 20 to become pellets, which are crushed in the variegated polyester waste cloth During the process, the water vapor and dust generated by the polyester material are pumped out by a blower; this can reduce the degree of hydrolysis in the post-processing process;

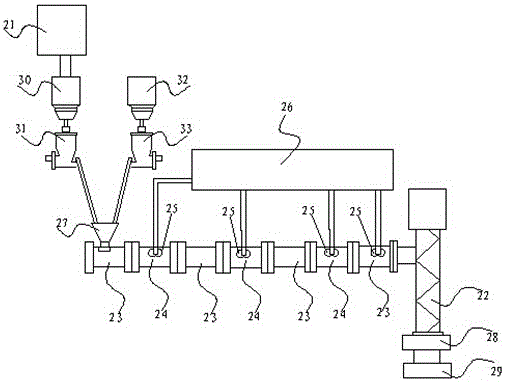

[0059] The front end of the extrusion mixing system is an extrusion section 23 and is provided with a mixt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com