Tire forming machine

A technology for tire building machines and building drums, which is applied in the field of tire building, and can solve problems such as transmission and positioning accuracy affecting tire building quality, weak adhesion of apex rubber bead rings, and poor composition ratio of capsule components, etc., to achieve novel structure, Improve the scope of application and design reasonable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

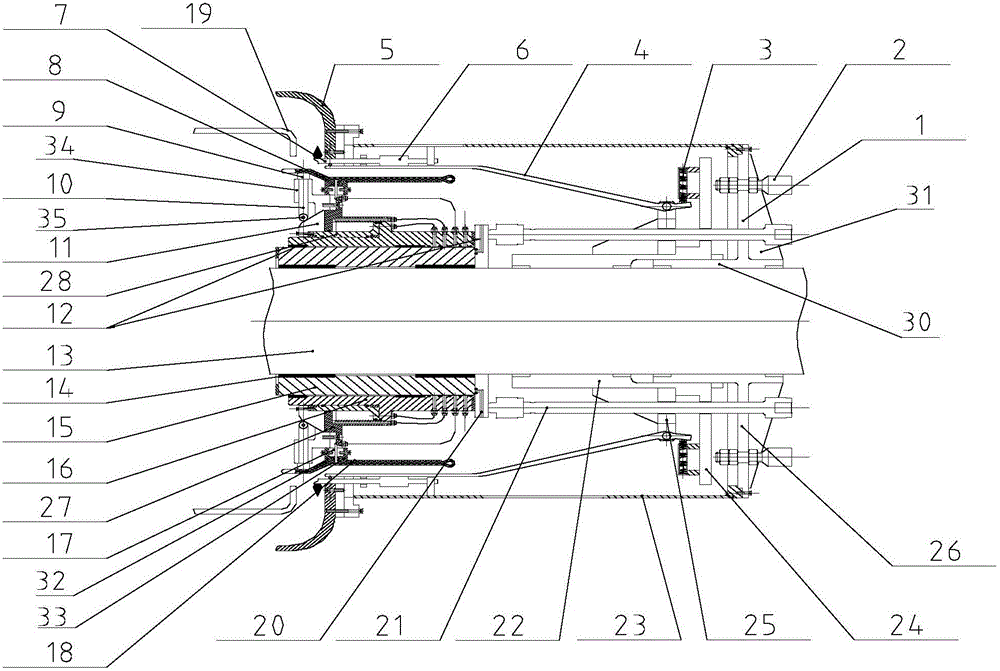

[0071] The present invention will be further described below in conjunction with the accompanying drawings.

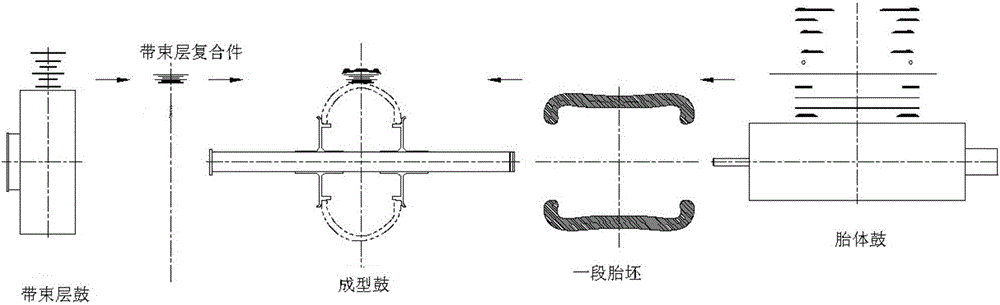

[0072] 1. Tire building machine

[0073] 1. Overall structure

[0074] A tire building machine, comprising: a carcass drum 19, a belt drum and a building drum, and the building machine also includes:

[0075] The first carcass transfer device, which is located between the carcass drum 19 and the building drum, realizes the transmission of the first carcass assembly between the carcass drum 19 and the building drum; the first carcass transfer device can rotate, and it includes a reverse package device;

[0076] a second carcass transfer device, located between the building drum and the belt drum, enabling the transfer of the second carcass component between the building drum and the belt drum;

[0077] The belt drum, the second carcass transfer device, the building drum, the first carcass transfer device, and the carcass drum 19 are sequentially arranged on the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com