Cell fixture pushing device and automatic welding machine using the pushing device

A push device and cell clip technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of affecting the production efficiency of lithium batteries, the large volume of ultrasonic welding machines, and difficulty in ensuring moving accuracy, and simplify ultrasonic welding. process, optimize the production layout, improve the welding accuracy and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

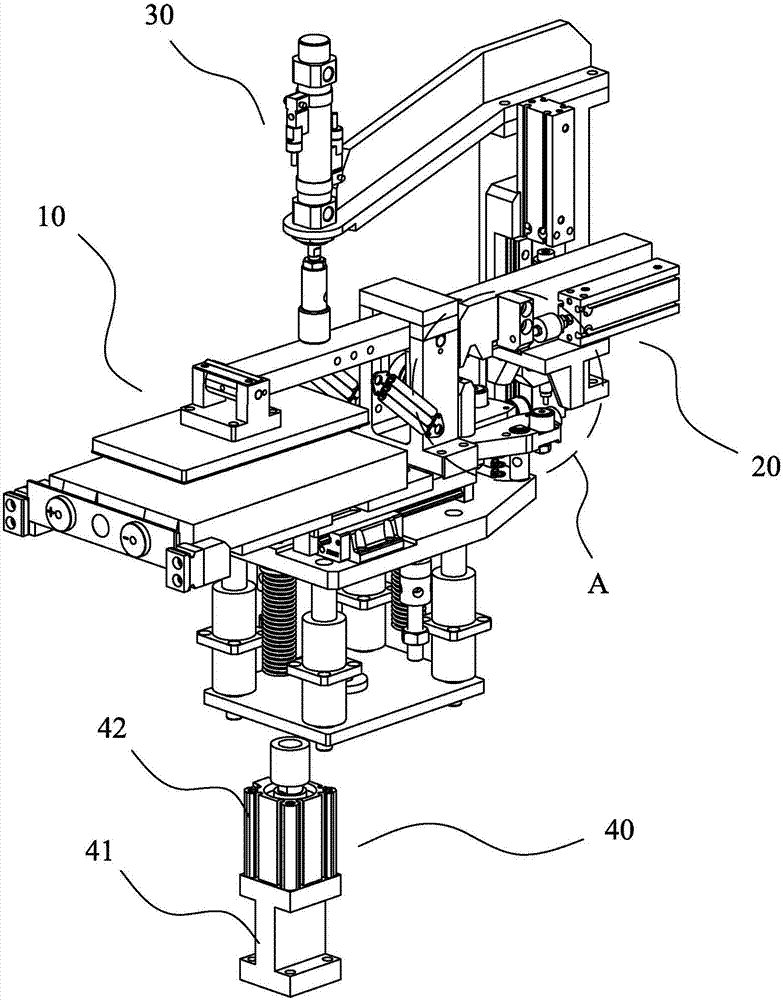

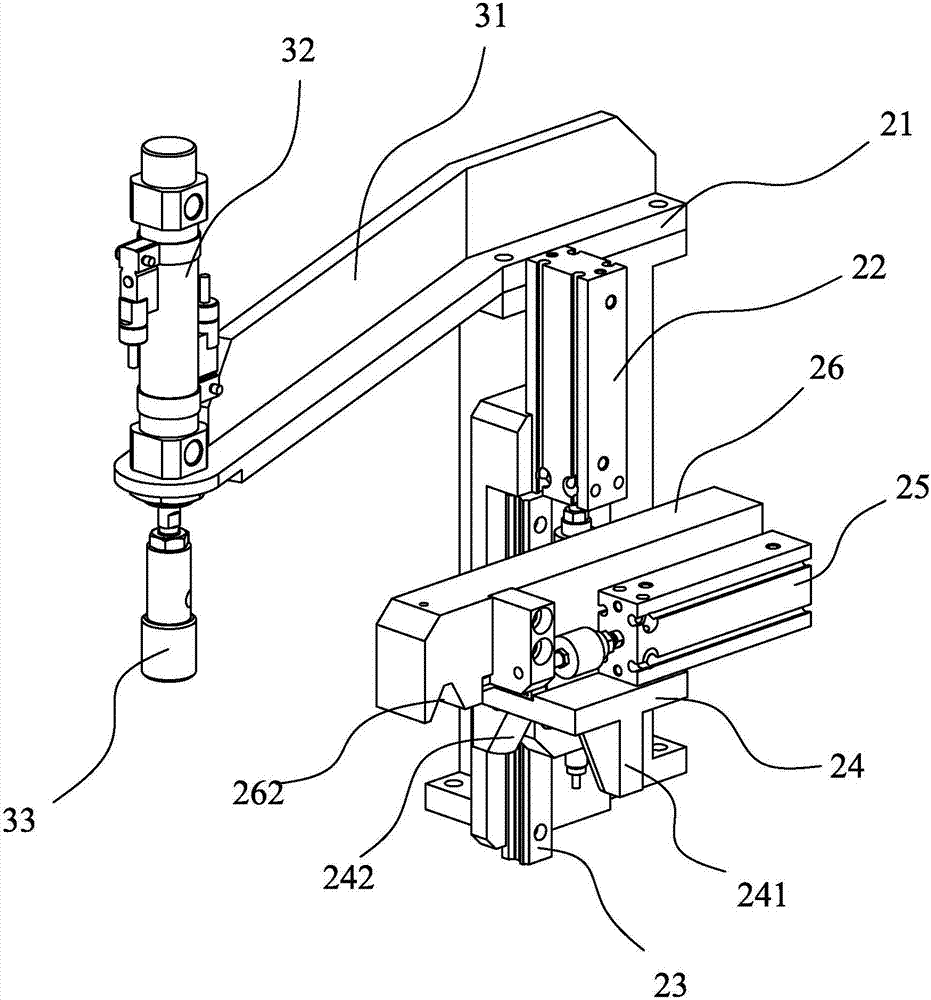

[0024] First, please refer to figure 1 As shown, a cell clamp pushing device includes a cell clamp 10, a pressing mechanism 30, a jacking mechanism 40 and a clamp pushing mechanism 20. The clamp pushing mechanism 20 is arranged behind the cell clamp 10 and is used to push The cells 50 on the cell fixture 10 are pushed forward; the pressing mechanism 30 is arranged above the cell fixture 10 for pushing the cells 50 on the cell fixture 10 downward; the lifting mechanism 40 It is arranged below the cell clamp 10 to hold the cell clamp 10 when the pressing mechanism 30 pushes the cell clamp 10 downward to prevent the position of the cell clamp 10 from shifting. The jacking mechanism 40 includes a telescopic rod. Push the cylinder 42 and the cylinder fixing seat 41 upward.

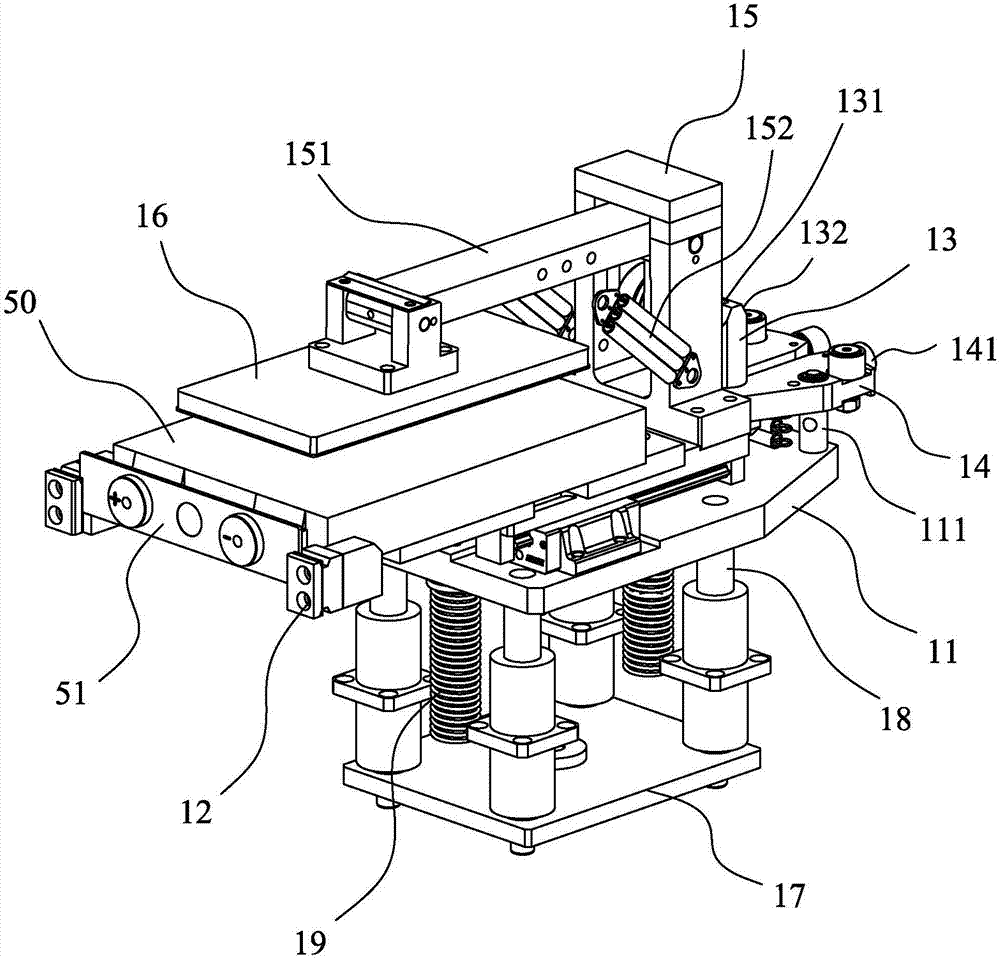

[0025] like figure 2 As shown, the cell fixture 10 includes a fixture bottom plate 17, a tray base 11, a cell pressure plate 16 and a cell tray 12. The tray base 11 is movably mounted on the fixture bottom p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com