Al-plated steel sheet for hot pressing and process for manufacturing al-plated steel sheet for hot pressing

A manufacturing method and a technology for steel sheets, which are applied in the field of manufacturing Al-plated steel sheets for hot pressing and Al-plated steel sheets for hot pressing, can solve the problems of reduced adhesion, deterioration of corrosion resistance, etc., and achieve excellent spot weldability and improved productivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

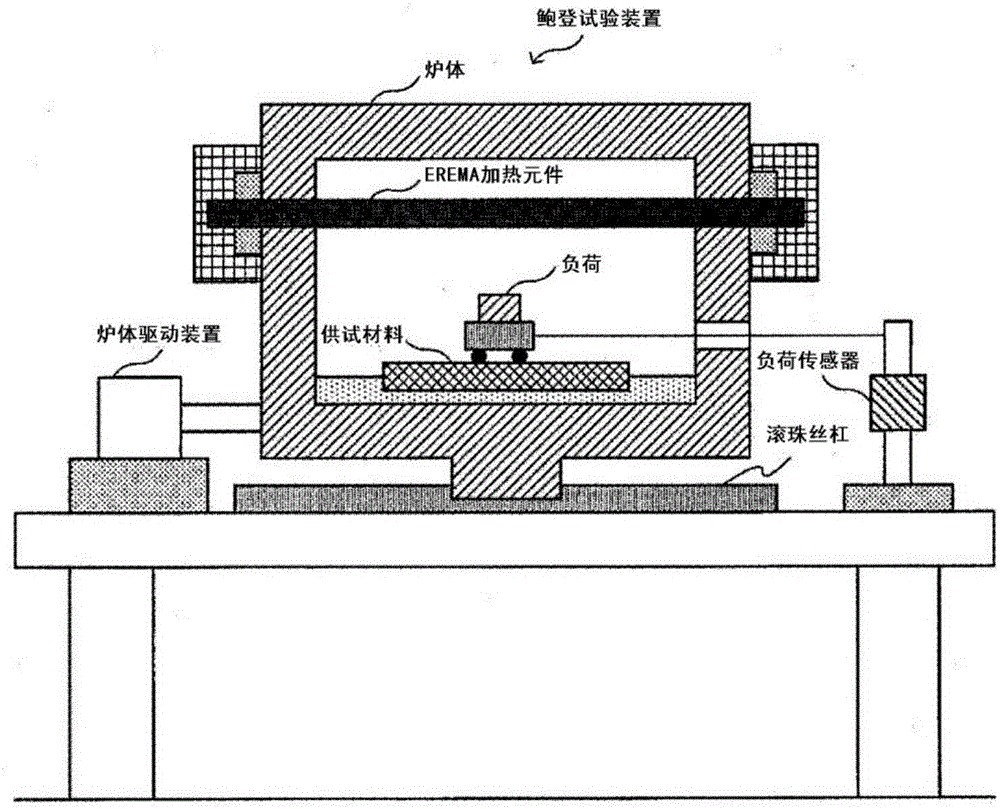

Image

Examples

Embodiment 1

[0104] In Example 1 described below, cold-rolled steel sheets (sheet thickness: 1.4 mm) having the steel composition shown in Table 1 were used, and the surface of the cold-rolled steel sheets was plated with Al by the Sendzimir method. The annealing temperature at this time is about 800°C. In addition, the Al plating bath contains Si: 9%, and also contains Fe eluted from the steel strip. The amount of adhesion after plating is adjusted to 80g / m on both sides by the gas wiping method 2 , After cooling, a coating solution containing any one of zinc oxide, zinc hydroxide, and zinc acetate was applied with a roll coater, and dried at the highest attained plate temperature shown in Table 2.

[0105] In addition, the contact angle, surface tension, and viscosity of the coating liquid used are shown in Table 1 below. Here, the contact angle, surface tension, and viscosity of the coating liquid were adjusted by adding water, Surfynol 104E, and / or Aron B500 to the coating liquid.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesion amount | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com