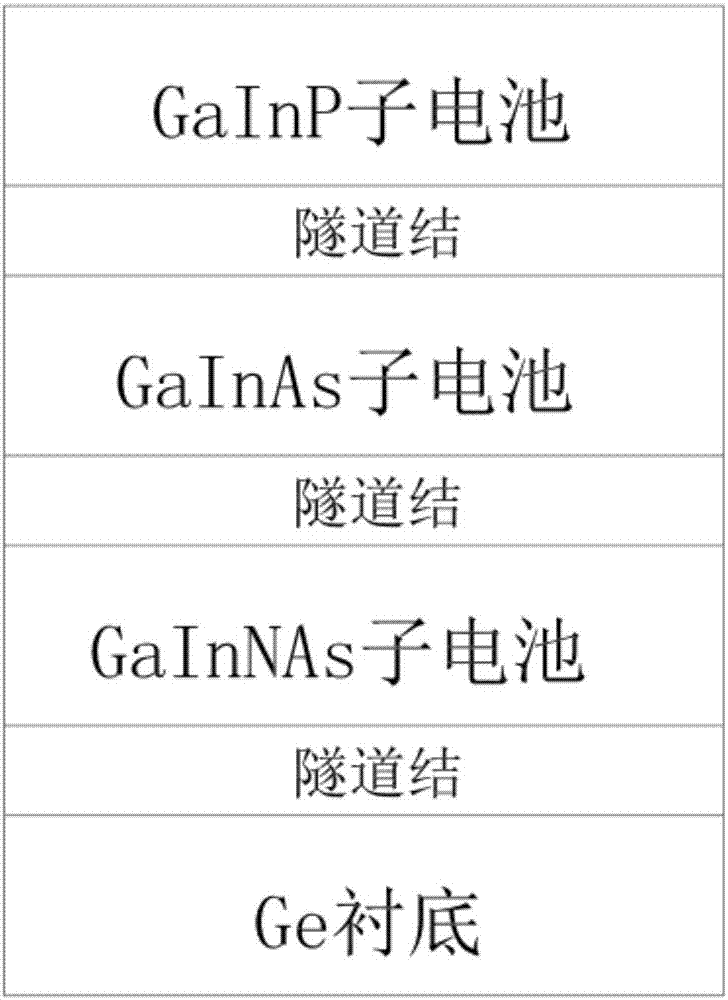

Method for growing high-quality gainnas sub-battery at high temperature by MOCVD

A high-temperature growth and sub-battery technology, applied in circuits, electrical components, gaseous chemical plating, etc., can solve the problems of increased difficulty in nitrogen doping and low utilization of nitrogen sources, so as to reduce the difficulty of doping and improve the overall performance, the effect of reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

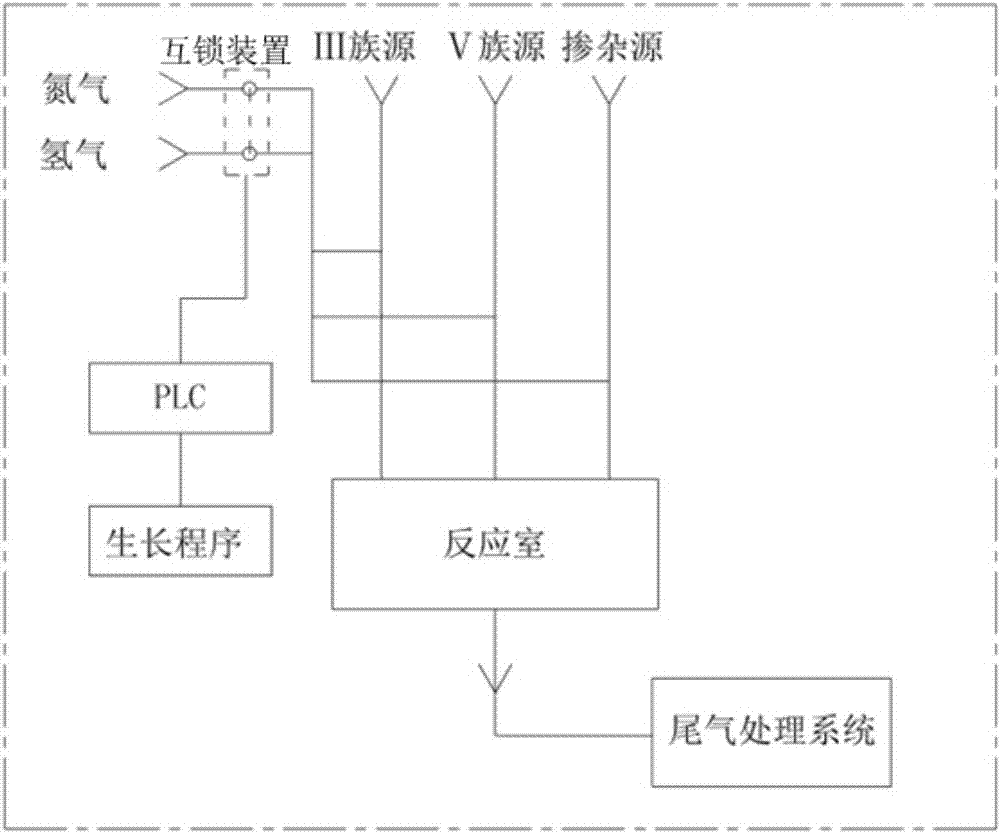

Method used

Image

Examples

Embodiment 1

[0020] The raw materials are prepared as follows:

[0021] Ga source: trimethylgallium (TMGa), saturated vapor pressure 113.64Torr;

[0022] In source: Trimethylindium (TMIn), saturated vapor pressure 2.58Torr;

[0023] C source: carbon tetrabromide (CBr4), saturated vapor pressure 0.82Torr;

[0024] Te source: Triethyltellurium (DeTe), saturated vapor pressure 9.33Torr;

[0025] N source: dimethyl trap (DMHy), saturated vapor pressure 165.9Torr;

[0026] Nitrogen (N 2 ) Purity: purity and volume percentage greater than 99.999%;

[0027] Hydrogen (H 2 ) Purity: purity and volume percentage greater than 99.99999%;

[0028] Arsane (AsH 3 ) Purity: purity and volume percentage greater than 99.9999%;

[0029] Silane (Si 2 h 6 ) Purity: purity and volume percentage greater than 99.9999%;

[0030] The above-mentioned different raw materials are put into the MOCVD reaction chamber according to the set procedure, and the high-temperature growth of the GaInNAs sub-cell of th...

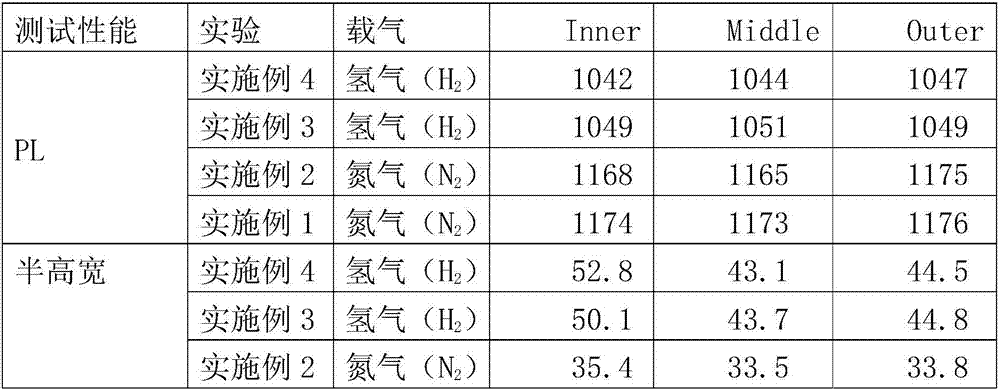

Embodiment 2

[0036] 1) Before growing the GaInNAs sub-cell, the carrier gas is hydrogen, and a layer of tunnel junction GaAs / AlGaAs needs to be grown to connect the Ge substrate and the GaInNAs sub-cell. The tunnel junction growth pressure is 30Torr, the thickness is 24nm, and the growth temperature is 540°C , the amount of hydrogen used is 80L / min, and the growth time is 90s.

[0037] 2) When growing GaInNAs sub-cells, the carrier gas is quickly switched to nitrogen, and the usage rate is 2.8L / min. When growing the GaInNAs sub-battery, the growth pressure is 39Torr, the thickness is 0.98um, the growth temperature is 590°C, and the growth time is 30min.

[0038] 3) After growing the GaInNAs sub-cell, the carrier gas is quickly switched to hydrogen, and a layer of tunnel junction GaAs / AlGaAs needs to be grown to connect the two sub-cells. The tunnel growth pressure is 30Torr, the thickness is 24nm, the growth temperature is 540°C, and hydrogen is used. The volume is 80L / min, and the growth...

Embodiment 3

[0040]1) Before growing the GaInNAs sub-cell, the carrier gas is hydrogen, and a layer of tunnel junction GaAs / AlGaAs needs to be grown to connect the Ge substrate and the GaInNAs sub-cell. The tunnel junction growth pressure is 30Torr, the thickness is 26nm, and the growth temperature is 550°C , the amount of hydrogen used is 90L / min, and the growth time is 90s.

[0041] 2) When growing GaInNAs sub-batteries, the carrier gas is hydrogen, and the usage rate is 3L / min. When growing the GaInNAs sub-battery, the growth pressure is 39Torr, the thickness is 1um, the growth temperature is 600°C, and the growth time is 30min.

[0042] 3) After growing the GaInNAs sub-cell, the carrier gas is hydrogen, and a layer of tunnel junction GaAs / AlGaAs needs to be grown to connect the two sub-cells. The tunnel growth pressure is 30Torr, the thickness is 26nm, the growth temperature is 550°C, and the amount of hydrogen used is 90L / min, the growth time is 90s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com