Closed switch blade switching type reversible switch for two-phase motor

A reversing switch, closed technology, applied in the field of two-phase motor closed knife switch reversing switch, can solve the problems of low safety, increased friction, poor electrical contact, etc., to improve electrical contact performance, reduce Small operational resistance and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

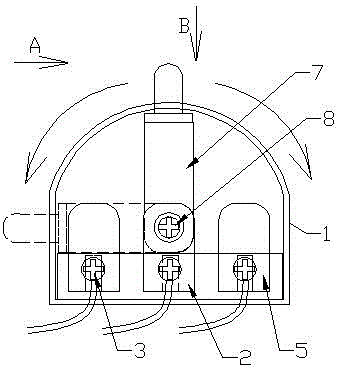

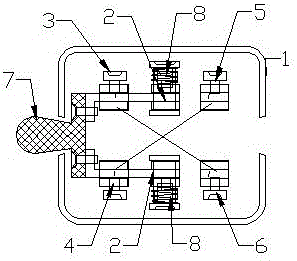

[0013] exist figure 1 , figure 2 , image 3 , Figure 4 In the middle of a closed arc-shaped shell 1, two middle contacts 2 are arranged horizontally, and the inverted contact A3 and the inverted contact B4 are horizontally arranged at the left end thereof, and the forward contact C5 and the forward contact are horizontally arranged at the right end thereof. D6. All the contacts are arranged horizontally in two rows and three columns. On the two middle contacts 2, a double-connected movable switch knife 7 that can be moved left and right by 180 degrees is movable. On the two middle contacts 2 and the double-connected movable switch knife A compression spring 8 is arranged horizontally on the movable connection shaft of 7, and the inverted contact A3 is electrically connected with the forward contact D6, and the inverted contact B4 is electrically connected with the forward contact C5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com