Special-shaped metal cantilever weighing device

A cantilever beam and metal sheet technology, applied in the field of weight sensors, can solve the problems of large size, large scale thickness, sensor installation, etc., and achieve the effect of high output sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

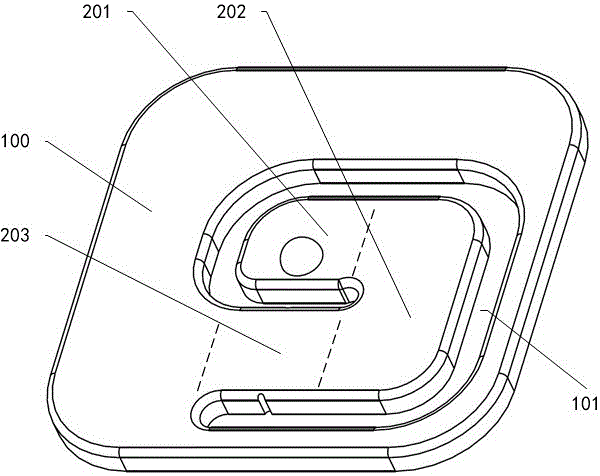

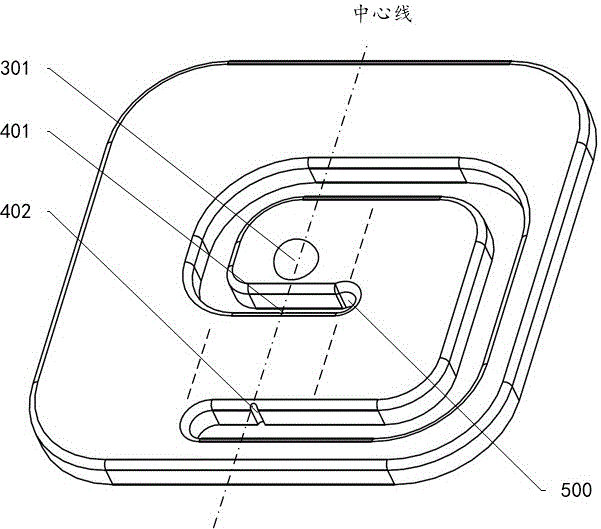

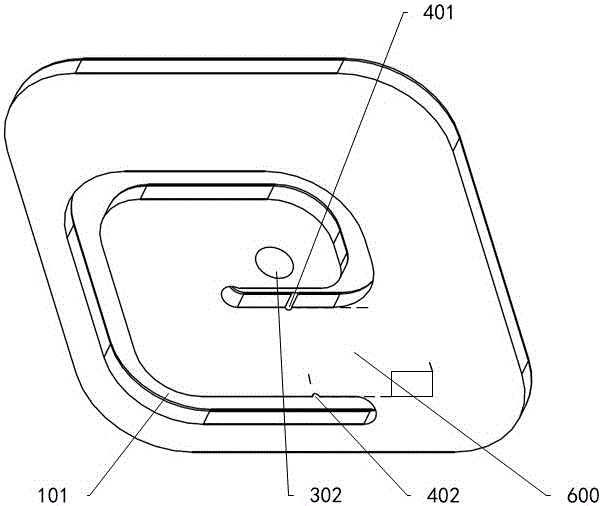

[0039] likefigure 1 As shown, the present invention provides a weight sensor for a scale, which is simple in structure, easy to install and manufacture, and improves the measurement performance of the scale. Formed, the metal sheet 100 and the hollow part 101 together form a cantilever beam shaped like a letter C, the hollow part 101 and the middle part of the metal sheet 100 form the cantilever beam front part 201, and the part perpendicular to the cantilever beam front part 203 is the middle part 202 of the cantilever, the rest of the cantilever is the rear part 203 of the cantilever, and the front part 201 of the cantilever is the free end, which has a front protrusion 301 and a corresponding front recess 302 .

[0040] Specifically, the width of the cantilever front part 201 is 10% wider than that of the cantilever rear part 203, so that the front protrusion 301 and the corresponding front depression 302 are formed at the same time as the cantilever front part (203) , with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com