A multiphase flow non-separation on-line measuring device and its measuring method

A measuring device and multi-phase flow technology, applied in the direction of detecting fluid flow by measuring differential pressure, volume/mass flow generated by mechanical effects, etc., can solve problems such as radioactive contamination measurement accuracy, save operating costs, and facilitate installation and handling. , the use of a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

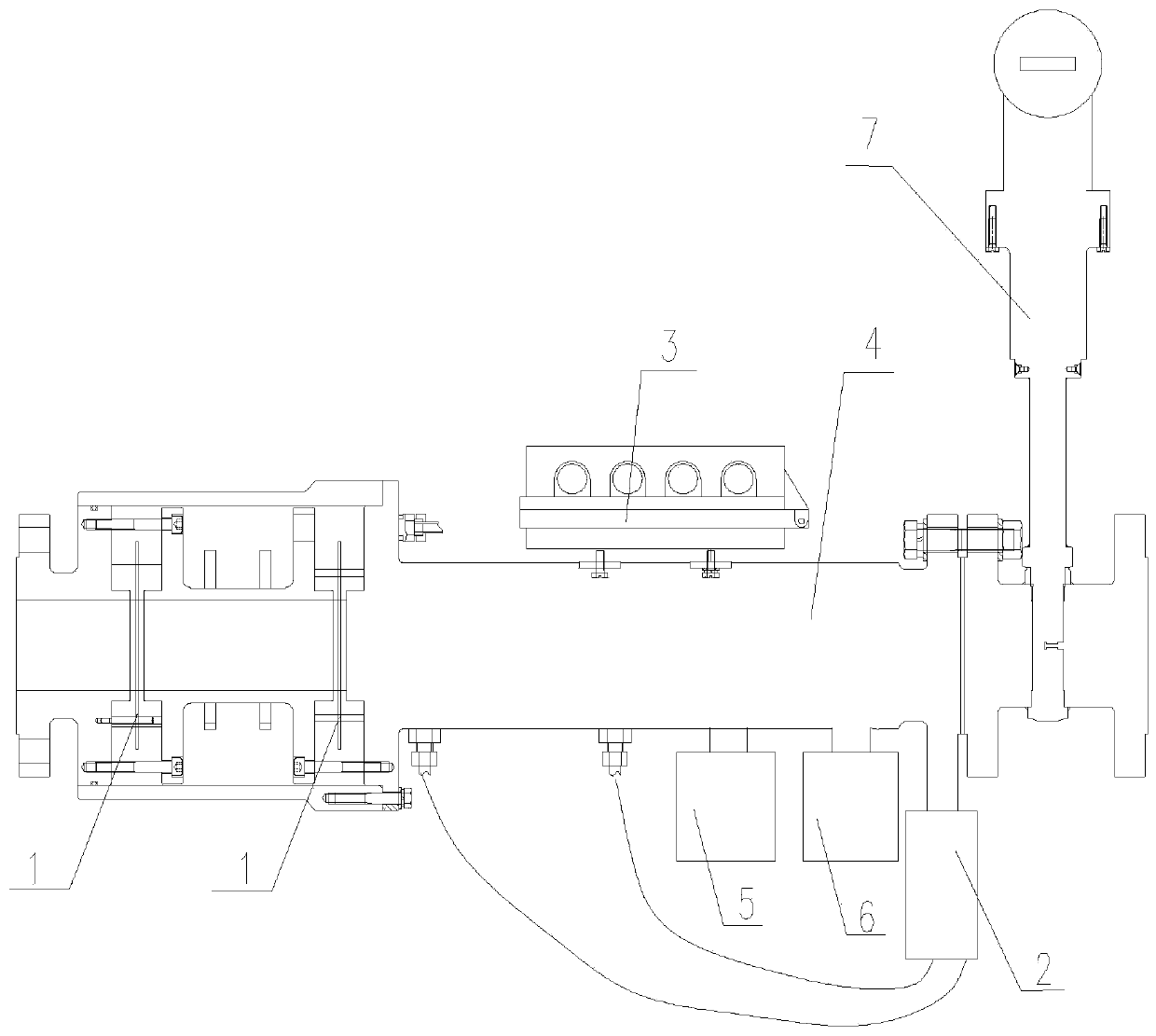

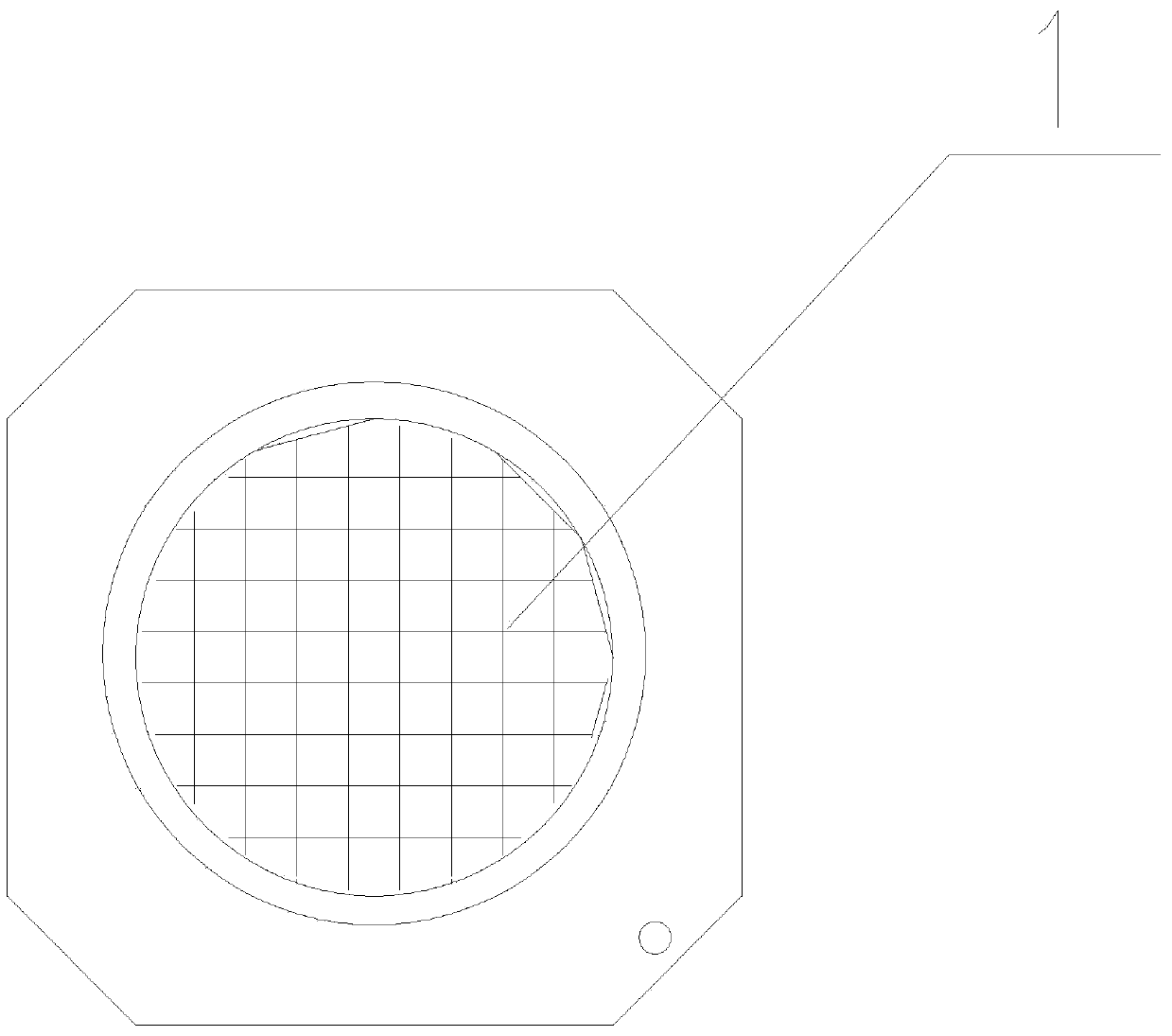

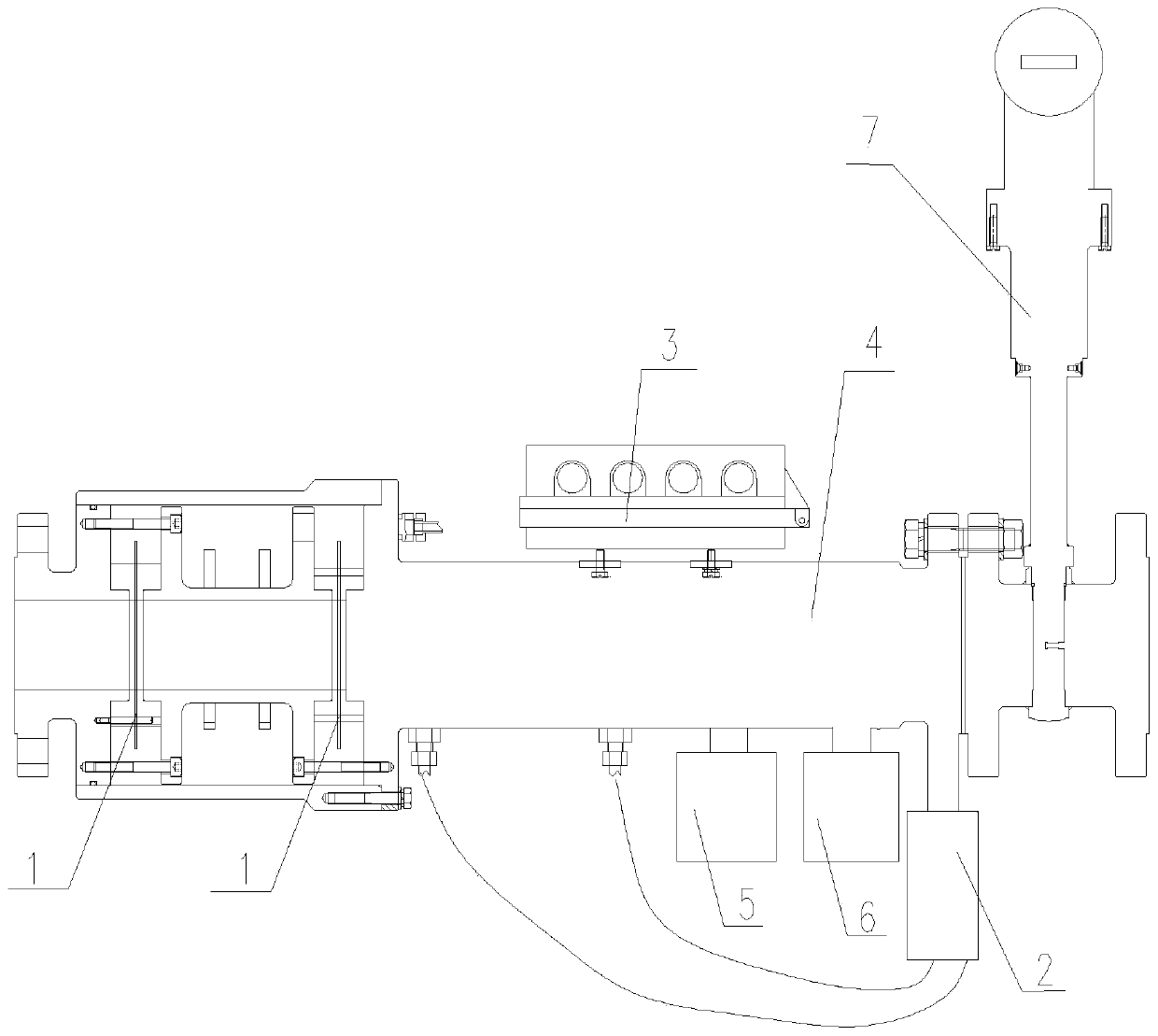

[0036] Such as figure 1 and figure 2 A non-separated on-line measurement device for multiphase flow is shown, a non-separation on-line measurement device for multiphase flow, including: a sensor module, a data acquisition processor 3, and the sensor module connected to the fluid pipeline includes: two or two The grid capacitive sensor 1 above is arranged in the fluid pipeline. The grid capacitive sensor 1 is composed of a number of excitation electrodes and a number of detection electrodes that are not connected. The excitation electrodes and the detection electrodes are arranged in a grid shape. It is used to measure the holdup and velocity of oil, gas and water phases; the data acquisition processor 3 is connected to the sensor module, and the data acquisition processor 3 is used to receive the measured fluid data and perform sorting and calculation.

[0037]In this embodiment, the sensor module also includes: a pressure sensor 5, a temperature sensor 6, a water content me...

Embodiment 2

[0047] According to the measurement method of a multiphase flow non-separation online measurement device described in Embodiment 1, the implementation process is as follows:

[0048] S1: When the fluid passes through a grid capacitive sensor 1, the grid capacitive sensor 1 transmits the measured data to the data acquisition processor 3, and sorts out the oil-gas-water phase fraction of the fluid;

[0049] S2: When the fluid passes through the two grid capacitive sensors 1 continuously, the two grid capacitive sensors 1 transmit the measured data to the data acquisition processor 3 to sort out the fluid velocity;

[0050] S3: When the fluid passes through the differential pressure measuring device, the differential pressure measuring device transmits the measured data to the data acquisition processor 3 to sort out the differential pressure of the fluid;

[0051] S4: When the fluid passes through the pressure sensor 5, the pressure sensor 5 transmits the measured data to the da...

Embodiment 3

[0060] According to the device described in Embodiment 1 and adopting the method of Embodiment 2, twelve groups of fluids are measured, and the measurement data are as follows:

[0061]

[0062] It can be concluded from the above table that the error of water content is within 2%; the error of liquid volume is within 5%; the error of gas volume is within 10%. The measurement with more accurate results and more convenient operation is realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com